ECO3, Formerly Agfa Offset Solutions, Celebrates 20 Years of Apogee with Most Feature-Rich Release Yet

Press release from the issuing company

Mortsel, Belgium – After two decades of success, Apogee automation workflow continues to lead the market, allowing customers to stay ahead of their competition and maximize opportunities in offset print production. Version 13, which is available as of today, builds in even more value with the introduction of user-specific upgrades that include extended support for product versioning, a multi-step online approval process, and more functionalities for packaging production.

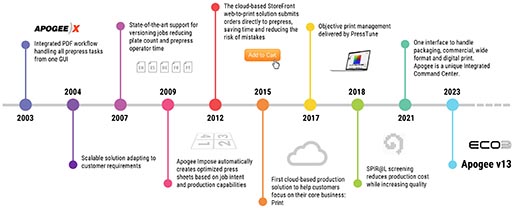

Sitting at the heart of offset operations across the world, ECO3's Apogee software solution has gone from strength to strength, supporting printers to deliver the best outcomes for their customers. Since ApogeeX 1.0 was first launched in 2003, the company has continually invested in the automated workflow in answer to general market trends and particular customer needs by introducing innovative improvements and new functionalities.

"The enduring success of Apogee is founded on our ongoing commitment to enhancing our solutions as we work side by side with our customers to help them meet the changing demands of the market," says Andy Grant, ECO3's Global Head of Software. "This latest update homes in on the specific needs of users in industries such as pharmaceuticals and FMCG (Fast Moving Consumer Goods) with new advanced automation and approval features that will help them simplify processes while safeguarding product quality and end users."

Adapting to market requirements

Offering automatic calculation of optimal imposition schemes, Apogee Impose was first introduced in 2012 to give printers more innovation and more value and to make their prepress process fit for the future. The solution is still being optimized in response to individual requests from customers and supported by new sustainable innovations such as the SPIR@L screening technology, which enables printers to achieve picture-perfect print quality while lowering ink consumption.

Meanwhile, the ever-expanding need for versioning capabilities gets a boost with v13. While already leading the market with the most advanced power, ECO3 has introduced support for automatic job setup based on CSV data from applications like Microsoft® Excel. Key job metrics specified in the spreadsheet can now be imported automatically to save operator time and avoid costly errors.

Simplifying user interactions

Approval tools have played a huge part in the user interface for print buyers for many years, with ECO3 responding to new technologies and demands by ensuring Apogee remains at the forefront of innovation.

The latest release sees a continued expansion of Apogee WebApproval with the introduction of multi-step online approval. Extending the existing functionalities, print jobs can now be set up to require the approval of multiple stakeholders in the value chain, helping to centralize, safeguard and simplify the process. Within this function, a new 'force approval' option is available, allowing customer sales representatives (CSRs) to override the approval process and instantly make the job ready for plating.

Apogee – the competitive advantage

Leading the market for 20 years, Apogee was the first workflow software on the market to embrace the PDF format, introduce FM and XM screening, and integrate color management tools, among many other breakthrough moments. Its Integrated Command Center concept is even more relevant today than when the first iteration, ApogeeX 1.0, was launched in 2003. This scalable solution is available for every size of prepress and printing operation whether it is for just one box or for 12 servers, for commercial offset, offset packaging production, proofing or digital printing. Depending on the printers' requirements, Apogee runs as a cloud-based solution or is deployed on-premise.

Grant states, "Over the past 20 years, more than 10,000 print operations globally have reaped the benefits of Apogee. By implementing the most agile software workflow on the market, they have gained a competitive advantage that allows them to deliver exceptional print quality to their customers while reducing costs and waste for highest productivity and better sustainability."

"Apogee's strength is in its simplicity. It was easy to use and required minimal effort to train operators. This allowed me to successfully manage my department and not run it. In the early days, proficiency was learned through trial and error. Apogee was different. You could take it out of the box and run with it with minimal training. It was like a tradesman developed it instead of a programmer writing it for the trade. Many disruptive technologies have influenced the printing industry, such as composite workflows, electronic imposition, CTP and JDF automation. Apogee continues to adapt with these technologies to help me stay ahead of my competition in print production."

BRAD CLARK, PREPRESS MANAGER - BURKE GROUP

"When digital prepress tools began to replace film-based stripping, ECO3 recognized that the PDF imaging model is robust and rich enough to serve as a digital master format for graphic art jobs," says Mark Lewiecki, Senior Product Manager at Adobe. "Based on this understanding, ECO3 built Apogee, one of the first PDF-based prepress solutions. Now, 20 years later, Apogee customers will enjoy the benefits of the latest release of Adobe PDF Print Engine – version 6. Happy 20th anniversary Apogee! I am happy to see that ECO3 is once again leading the industry, with new cost-saving automation features and collaboration tools built into Apogee v13."

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.