UFlex Exhibits a Wide Range of Innovative and Sustainable Printing and Packaging Solutions at Plast India 2023

Press release from the issuing company

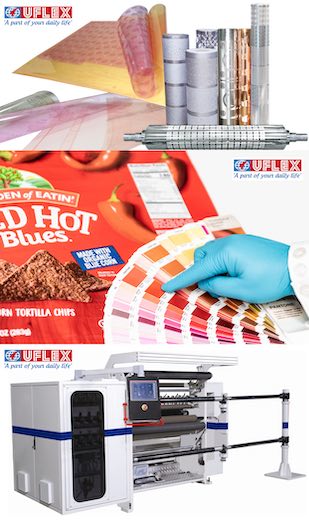

Noida: UFlex Limited, India’s largest multinational flexible packaging and solutions company, is exhibiting its wide range of Printing Cylinders, Inks, Adhesives, Coatings, Advanced Printing, Laminating, and Slitting Machines from February 1-5, 2023 at booth no A-06, Hall No 11, at Plastindia 2023, Pragati Maidan, New Delhi.

At the show, UFlex’s Engineering Business will unveil its Single Station ELS printing machine with an enhanced feature that reduces the changeover time considerably. The Engineering Business will display its innovative solvent-less lamination machine ‘Standard SPL’, which allows simultaneous lamination of printed laminates at the speed of up to 400 meters/minute on different substrates having heterogeneous mechanical and chemical properties. The Engineering Business will also showcase its robust slitting machine Ecoslit 600, a high-speed compact duplex slitter and re-winder with wide web width ranging from 800 mm to 1300 mm, which enables seamless slitting experiences for converters.

The UFlex Chemicals Business will showcase its complete range of solutions catering to the multiple Flexible Packaging application, offset, narrow web, and corrugated packaging applications such as green inks, adhesives, and coatings that play an instrumental role in the development of packaging applications and enhance sustainability.

The UFlex Printing Cylinders business will display a wide range of embossed rotogravure laser engraved cylinders, printing cylinders, and flexo plates for water-based inks that deliver razor-sharp print finesse on multiple substrates. The business will also showcase other premium printing solutions such as its Flexcel NX Flexo plate that delivers 100% pixel-for-pixel accuracy in imaging with Kodak’s squarespot imaging technology to deliver supreme print quality. A Flexcel NX Flexo plate, when combined with Thermal Imaging Layer (TIL) film, unleashes accurate image reproduction from file to finished plate with the highest resolution mask in the graphic arts industry so far. This film requires 3 to 4 times less energy when compared to a traditional laser ambition mask (LAMS) layer and eliminates inconsistencies in mask imaging.

Meet with the UFlex business teams at A-06, Hall No 11 at Plastindia 2023.

For any questions, please email us at: [email protected] / [email protected]

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Only verified members can comment.