Arti-Bau Invests in 2nd Mark Andy Digital Series Press

Press release from the issuing company

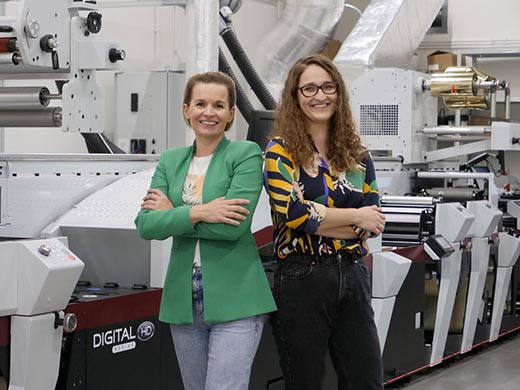

Arti-Bau President Monika Stefanska (left) and Urszula Lewandowska with the company's second Mark Andy digital hybrid press, the DSHD model.

It was in 2017 that Arti-Bau, the Polish label converter based in Sleza, near Wroclaw, became the first European user of a Mark Andy Digital Series hybrid press. Monika Stefanska, President of the printing company, believes that the investment was a milestone in the company’s development. It enabled Arti-Bau to print and finish highly advanced, sophisticated labels, including peel-off in one-pass - and peel-off labels have since become a company specialty.

The new press brought a massive growth in orders, and when Arti-Bau decided to extend its capacity, it once again turned to Mark Andy. The result was that in February ’22, it moved to a new site and started production with the latest highly efficient Digital Series HD hybrid press, equipped with numerous additional options.

LEARN MORE on the video https://youtu.be/uJjiudXuk4A

European pioneers of Mark Andy digital hybrid printing technology

This year marks the 10th anniversary of Arti-Bau, and its print capability has always been based on digital printing, specialising in self-adhesive label production. The company has systematically built and strengthened its position in the Polish and European markets, while investing in new, modern solutions.

Monika Stefanska explained: “We have always been aware that labels are an essential part of everyday life – but they can be very demanding of technology. We have noticed many market changes: decreasing orders, growing demand for versioning, and variable data printing, as well as customers’ growing requirements in terms of quality and punctuality. We have also tracked different technological solutions and paid special attention to hybrids. But, as a manufacturer of all components in a hybrid press, Mark Andy stood alone.”

This first Digital Series hybrid press increased Arti-Bau’s capacity by up to 50% and enabled it to manufacture more sophisticated labels that had been impossible previously. This allowed Arti-Bau to develop business with a new group of customers. “Printing and converting labels in one pass moved us to a completely new level of quality and effectiveness,” confirmed Urszula Lewandowska, who is responsible for production planning at Arti-Bau. “So, when we looked for a new press, we opted for the more developed version that has additional flexo units and corona treatment.”

Mark Andy for the second time

“Time goes so quickly, and recent years have shown us very clearly how labels are central to our lives. The past two years have brought us major growth from the food and cosmetic industries. The first Digital Series has been a very reliable and stable press, but even after establishing a second shift, we felt we needed to purchase a quicker and more efficient solution. Five years is almost an era in digital technology, so we asked Mark Andy to help us choose the best new solution,” said Monika Stefanska.

Lukasz Chruslinski, European Sales Manager at Mark Andy commented: “I have been working with Arti-Bau since the company started and it’s been enormously satisfying to see how dynamic its development has been. We are very proud that the Digital Series we delivered in 2017 has been a key stimulus for Arti-Bau’s progress and market success. And because it was the first in Europe, it also has a special significance for us.”

Close cooperation with a supplier, based on a mutual trust, is an essential part of each printer’s success, according to Monika Stefanska. “Mark Andy is a manufacturer of top-class equipment, but what’s equally important is that it is a reliable advisor and business partner.” She says that the company’s Warsaw-based service hub was crucial to Arti-Bau’s decision to buy both hybrid presses from Mark Andy. “I guess it’s the right time to thank everyone at Mark Andy for the help and support they gave us at every step of the way: installation, staff training, and daily production.”

Mark Andy Digital Series HD: faster, better, more efficient

“To be honest, we were forced by the market and our customers to buy a new press, as their expectations of quality, efficiency, and on-time delivery have increased,” she explained. So, when the company decided to move to a new site, it decided to buy a new press instead of relocating the existing one. Production at the new location began in February, when the new Mark Andy was delivered.

Considering the type of work they do, and with five years’ experience of hybrid technology, the managers at Arti-Bau elected to equip the new press with additional options and functionalities. “Year on year we have produced an increasing number of highly processed, embellished labels, including peel-offs. We apply them to premium products, including eco-friendly food, so we equipped the new press with a flexo station after the inkjet unit and a corona treater for curing the ink,” said Monika Stefanska.

Mark Andy was also on-hand to oversee operation of the new press, according to Urszula Lewandowska. “Because the Digital Series HD applies much smaller ink droplets, the web control system and very intuitive software that drives the press and process files are a real success,” she said.

Lukasz Chruslinski added: “It’s worth mentioning that a technological upgrade of the inkjet unit that now prints in 5 colours, also offers far higher resolution. It applies smaller ink droplets to the web that is run on a curve and is equipped with a web reversal system and Gizmo module for peel-off production.” The simplified head-cleaning system is also an important part of the new press. Digital Series HD offers one more innovation when comparing it with the previous model: the colour registration in the digital unit is achieved without stopping a press. “This is a new feature that we introduced at the beginning of this year,” he added.

Mark Andy: partnership, advisory, professionalism

According to Monika Stefanska, choosing Mark Andy as a strategic partner was based on the technological advantages of its presses, innovative solutions, and the individual skills of Mark Andy’s local team. “We have always believed in the unwritten principle that business and business relations are created by people, not companies. This approach has enabled us to establish very close relationships with our customers, some of which have been with us from day one!” she said.

The same applies to suppliers. “We have worked with Lukasz Chruslinski for more than 10 years, so we knew we could expect a high level of professionalism from him. But, as another unwritten principle states, the second press is sold more by the service than the sales team. From this point of view, Mark Andy has excelled as a technical advisor. This was very important as we were the European pioneers of Mark Andy hybrid technology - so it was a kind of a breakthrough implementation.”

Lukasz Chruslinski agreed: “We were very conscious of how important this investment was and made sure we supported the customer at every stage. We were also able to gather information about the press from Arti-Bau’s press operators and managers. This kind of feedback is very important for developing the next generation of presses, and it applies to the Digital Series HD because some of its technology and upgrades were based on information brought to us by the users of the first-generation Digital Series.”

New site, new press, further development

Monika Stefanska says hybrid technology opened markets with new customers, some of which had no concept of what digital print could offer. What they quickly appreciated was its one-pass production capability. At a time when quality is ‘a given’, customers also demand efficient production of short and medium runs, where quality and punctuality are more important than price alone.

The new press has been fully booked almost from the first day and works two shifts. Besides streamlining the handling of Arti-Bau’s customers, it has also opened capacity for new orders. “So, we have intensified our sales activities,” said Monika Stefanska. “We participated in the Warsaw Pack trade fair with our own booth, and are planning more of this type of activity, including other trade fair and events that attract current and prospective customers. With Digital Series HD on a board, we have huge potential for further growth.”

Speaking for Mark Andy, Executive Vice President Tom Cavalco summed up: “Cooperating with printers who pioneer new technology is always special for us and seeing how a customer like Arti-Bau develops gives us great satisfaction. We’d like to thank Arti-Bau’s management for its trust in us when they decided to install our first Digital Series in Europe in 2017, and again in 2022, when they purchased our latest hybrid solution. We are convinced that the new Digital Series HD will be a major boost for Arti-Bau, driving its dynamic growth even further.”

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.