Konica Minolta’s MGI JETvarnish 3D Evo Sets Post Press Apart from Competition

Press release from the issuing company

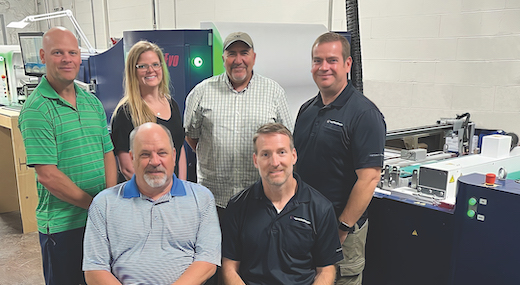

Post Press Specialties employees in front of their newly installed Konica Minolta MGI JETvarnish 3D Evolution (Evo) 75. Bottom Row (L to R): Andy Humble, President and Owner; Jacob Bagnell, Plant Manager. Top Row (L to R): Matt Jackson, Sales; Angela Graham, Accounting/HR; Dennis Robinson, Supervisor; Bowen Griffitt, Lead Estimator/Office Manager.

Finisher Increases Capabilities and Enhances Client Jobs with New Equipment

Ramsey, NJ -- Konica Minolta Business Solutions U.S.A., Inc. (Konica Minolta), a leader in industrial and commercial printing and packaging solutions, today announced the installation of its MGI JETvarnish 3D Evolution (Evo) 75 at Post Press Specialties (Post Press) in Independence, Missouri.

As a trade bindery, all of Post Press’ work comes from printers and marketing companies already printed and ready to be finished. Its impressive 170,000 square-foot facility houses dozens of die cutters and folders of various size and types, as well as film laminators, tippers, saddle stitchers, inserters, ink-jet systems and much more. The company produces high-end show pieces, from book covers and invitations to folded cartons and mailers, enhancing the work with its MGI Classic press. A huge advocate for MGI embellishment, Post Press educates its customers on what it can do for them on a job-by-job basis, such as using texture and depth to enhance their print.

Post Press was one of the first in North America to utilize MGI technology, and after reviewing other systems when looking to upgrade, chose Konica Minolta again, which resulted in the improvements they were seeking. The company can now take on work it previously had to turn away because its equipment was not a great fit for certain jobs. The MGI JETvarnish Evo’s scanner saves Post Press many hours in make readies, and with the help of the Corona Surface Treatment System (CSTS), it has fewer issues bonding to customer inks.

“At Post Press we strive to provide the best of bindery to our customer base. The MGI JETvarnish 3D Evo adds services I knew our clients could and would use, and we believe it sets us apart from other traditional trade binderies,” said Andy Humble, President and Owner of Post Press Specialties. “Customers have been very impressed with the detail that can be achieved with the foil and also how well it registers to their print. Our confidence in what the machine can do allows us to stand behind it when taking on new projects.”

“The versatility Post Press has created through its massive facility of finishing equipment is beyond impressive, and allows them to serve so many different types of customers. We are proud to be part of their operation,” said Bill Troxil, President, Industrial Print and Production Print Business, Konica Minolta. “Our ongoing partnership allows us to fulfill their needs as their business grows and evolves, and we couldn’t be more pleased at the awareness they are creating for embellishment by teaching their customers how it can enhance their printed products.”

Delivering dynamic performance for the most demanding applications, the MGI JETvarnish 3D Evolution (Evo) 75 gives extra added value and sensory dimensional textures to printed output. Available in two different widths – 52 x 120 cm/ 20 x 47” and 75 x 120 cm/ 29 x4 7” – the 3D printing series has been specially designed to offer digital and offset printers a scalable upgrade path for a full range of production environments and postpress applications. The MGI JETvarnish 3D Evolution employs the Artificial Intelligence SmartScanner (AIS), which uses AI to create an automatic varnish and hot foil registration for inkjet heads over the preprinted sheet.

Learn more about Konica Minolta’s MGI JETvarnish 3D Evolution (Evo) 75 here.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.