Raff & Wurzel Invests in High-Performance Printing Technology from Koenig & Bauer

Press release from the issuing company

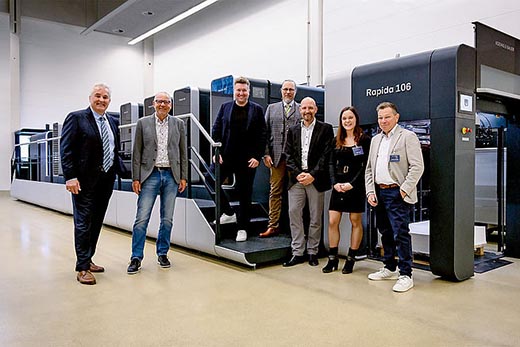

Photo call in front of a similarly configured press (left to right): Reinhard Marschall, managing director of Koenig & Bauer Germany; Peter Dankesreiter and Christopher Sommer from P2 MedienInvest Holding; Thomas Grübner, managing director of Elbe-Leasing; Markus von der Grinten, Koenig & Bauer Germany; Katja Lorenz, Elbe-Leasing; Thomas Uehling, managing director of Raff & Wurzel.

Rapida 106 X from Koenig & Bauer promises a clear technological advantage

- Up to 20,000 sheets/hr in 4-over-4 production as well

- Fast makeready and high process automation

- Extensive inline quality control

- Equally cost-effective for long and short runs

At the beginning of the month, Raff & Wurzel Druck from Riederich in the south-west of Germany ordered a new high-performance press from the Rapida 106 X series made by Koenig & Bauer. It is scheduled to enter production in the late summer. The company has celebrated a very successful first business year since its relaunch in February 2021, and views the investment as vital preparation for further growth and future market challenges.

The eight-colour perfector press with additional inline coater is replacing a six-year-old sheetfed offset press in a similar configuration for the 3b medium format. It also defines new benchmarks in terms of performance – with production speeds up to 20,000 sheets per hour, and this in perfecting mode as well, with significantly more automation, and with extensive inline quality control features. The resulting benefits will give Raff & Wurzel the major technological advance it desires.

Raff & Wurzel belongs to P2 MedienInvest Holding, established by Peter Dankesreiter and Christopher Sommer. Their declared aim is to realise synergy effects along the entire value chain within the print and media industry. This objective also guides all activities by Raff & Wurzel. In its role as a print service provider, it implements lean and essentially automated ordering, production and logistics processes, and manages the decentralised marketing activities of its customers if they so wish. Customers who require only one particular service from the comprehensive portfolio can nevertheless expect a similar welcome. Networking with Wurzel Digital and others enables expansion of the portfolio to include document creation and image processing, as well as CGI visualisations, animations and interactive applications as well.

Increased print capacity

Managing director Thomas Uehling is already looking forward to the arrival of the new press: “Our production has been running at its limits over the past months. The new press will give us capacity reserves – including ones for additional jobs.” Uehling’s priorities are maximum availability, significant advances in process optimisation, the highest possible quality and a similarly high level of production reliability.

Accordingly, QualiTronic PDFCheck with its functions for colour control, sheet inspection and comparison of the printed image with a pre-press PDF, DriveTronic SPC and CleanTronic Synchro for fast job changes, and the LogoTronic performance package with PressProduction and OEE reports, are among the most important items on a long list of press features. On this basis, offset printing becomes profitable for run lengths involving as few as 300 sheets.

Even short runs are expected to be produced at high speed in perfecting mode. Thomas Uehling: “If this allows us to handle three extra projects every day, that will be a great help.” Christopher Sommer adds: “At the same time, the press will close a few gaps and enable us and our customers to address new market segments.” Peter Dankesreiter is equally pragmatic in his assessment: “The Rapida will even allow a number of smaller jobs to be handled profitably which would otherwise be assigned to a web press. But it is also ideally positioned between digital and offset printing.”

Focus on ecology

Alongside the quality control systems, which serve to reduce waste and potential customer complaints, further equipment details contribute to environment protection and resource efficiency in the print process. They include the VariDryBlue dryer systems, which recirculate the only partially saturated hot air from the first dryer modules in order to minimise overall energy consumption. Thanks to water cooling, waste heat from the press can be used to heat offices and production spaces. Low-alcohol printing, on the other hand, has meantime practically become the standard in the print industry.

Successful cooperation on the commercial side

One particular success story is the cooperation between Raff & Wurzel, P2 MedienInvest Holding and Elbe-Leasing as their financing partner. Where larger financing companies tend to view business with SMEs solely from the perspective of opportunity and risk assessment and follow what are essentially standardised procedures, a specialist with a background in the graphic arts is often able to offer print companies a more compelling master plan. Despite the fact that Raff & Wurzel and P2 previously only knew Elbe-Leasing from social media, the three partners quickly established a basis for trustful cooperation.

The relationship with Koenig & Bauer grew in much the same way: “We simply got on well with each other,” Peter Dankesreiter recalls. “Our meetings were open and transparent from the very beginning.” Christopher Sommer points out that the technologies and features of the Rapida 106 X are a perfect fit for the business concept pursued by Raff & Wurzel. Thomas Uehling has only praise for his team, to which the company owes the success it has enjoyed over the past year: “I can sense a similar level of commitment at Koenig & Bauer.” Reinhard Marschall, managing director of Koenig & Bauer Germany, thanked his counterparts for the confidence they had shown in his company’s abilities. “Our companies can both point to long traditions and are quite similar in their approach. I am looking forward to our continued cooperation.”

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.