Koenig & Bauer Durst Delta SPC 130 Centerpiece for Rondo’s New Dedicated Print Production Plant

Press release from the issuing company

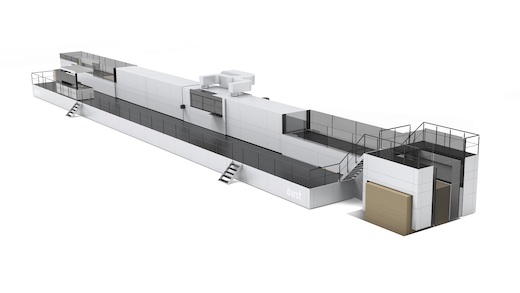

The Delta SPC 130 FlexLine is the heart of the new production hall for corrugated board

- Double celebration planned for corrugated box manufacturer

- Brands continue to drive transformation to meet changing market demands

- Koenig & Bauer Durst brings complete digital printing solution for food packaging

Würzburg, Germany–Rondo Ganahl, one of Europe’s foremost corrugated board and packaging manufacturers, has unveiled plans to celebrate its 50th anniversary milestone and official opening of a digital print production plant in a €25 million investment. The company in Styria, Austria, is determined to capitalize on continued business growth where digital production volumes continue to rise by 25 to 30% a year.

Taking center stage in the dedicated digital production facility is Koenig & Bauer Durst’s Delta SPC 130 single-pass press with water-based ink technology that is driving business growth and providing the food packaging industry solutions demanded by brands. The Delta SPC 130 has been successfully transferred across to the new plant and production has started as planned from the start of April.

The official opening ceremony for the new building together with the 50th anniversary celebration of Rondo St Ruprecht will be in September. The firm, which is part of the Rondo Group that has eight plants across Europe, invested in the Delta SPC 130 three years ago to start digital production – and has never looked back. About 90% of the Rondo digital printing business is for the food industry.

With lead times continuing to go down, Rondo says it must further develop the digital technology where the excellent print quality already matches litho production.

Karl Pucher, Managing Director of Rondo Ganahl St. Ruprecht, said: “It has been an incredible success story. Digital printing was a big step for us three years ago with an unknown future, but we have never looked back. The transformation is being driven by brands who need to get products to the market quickly, and with digital printing we are very fast from development to getting the products to customers, among them Lindt & Sprüngli who are very big in display products and have been with us on our digital journey from the start.”

“Digital printing is the future and is really helping us get a whole raft of new customers. Quality is no longer a topic of conversation. Digital is a very important development for us because we now have a total solution for our customers that has been integrated into our whole plant process. We are running the SPC 130 very well in a two-shift operation, sometimes even in three shifts. We have a lot of customers in the food industry and one of the main reasons for going with Koenig & Bauer Durst is because of its food-safe inks. They provided all permissions we need for the food industry.”

Mr Pucher added: “The interaction with Koenig & Bauer Durst is excellent – we are very happy with the support. We didn’t just buy a machine. We bought a complete system. The software is the main part because it helps us to optimize the printing and make the right decisions for customers.”

Robert Stabler, Managing Director, Koenig & Bauer Durst, said: “In a true partnership approach, we have been with Rondo every step of the way from its start in digital printing. Investing heavily in a dedicated digital production plant speaks volumes about where markets are heading – all driven by brands. “Converters increasingly recognise that they need a highly automated, reliable, versatile, and all-in-one digital solution for fast turnaround of jobs. Rondo is also a perfect example of how companies ensure jobs run seamlessly through their plants by investing in complete workflows and colour management systems.”

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.