Optimizing the Production of E-Commerce Packaging with Innovative Gluing Solutions

Press release from the issuing company

At this year’s CCE International, the focus at the Baumer hhs stand in Hall 4a (2440) will be on innovative solutions for applying pressure-sensitive adhesive in the production of e-commerce packaging.

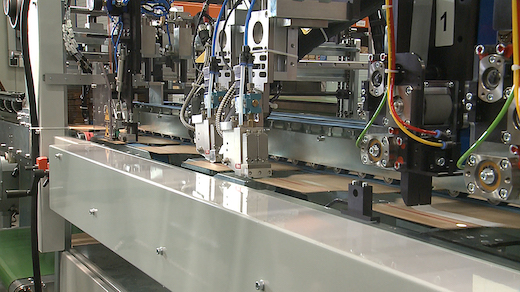

Krefeld – At this year’s CCE International (15 -17 March 2022 in Munich), Baumer hhs will be focussing on its new gluing systems developed for the e-commerce segment (stand 2440, Hall 4a). Solutions will be presented that meet virtually all requirements of the market for applying pressure-sensitive adhesive on e-commerce packaging.

“Baumer hhs is one of the specialists when it comes to developing high-performance gluing solutions for e-commerce applications. All over the world, machine manufacturers and packaging producers in the e-commerce segment put their trust in the flexibility and reliability of our equipment. We cordially invite visitors to CCE International 2022 to talk with our experts. We’re excited to show you how you can optimise the efficiency, quality and sustainability of your gluing process in the production of e-commerce packaging using the latest equipment from our company”, says Thomas Walther, head of Business Development at Baumer hhs.

Baumer hhs’s new solutions, optimised to meet the varied requirements of the e-commerce market, give packaging producers decisive advantages. For example, in the production of shipping boxes made of heavy-duty corrugated board, the tank on the new 100-kg Xmelt melter is designed to guarantee optimum, highly energy-efficient melting of the (pressure-sensitive) adhesives. The melter’s flow regulator feeds the adhesive very consistently, enabling exceptionally uniform gluing on heavy-duty corrugated board within narrow tolerances and across all speed ranges.

The fluid mechanics of the nozzle on the proven application head from Baumer hhs have been re-engineered to support homogeneous glue application from start to finish. Particularly at high application weights up to 500 g/m2, the head applies the adhesive even more uniformly. “The undulating surface of heavy-grade corrugated board requires consistent and high-quality application of between 250 and 500 g/m2 of adhesive to even it out, so that e-commerce packaging made of this material can be sealed easily and with little effort”, Walther explains.

With its new equipment, Baumer hhs also supports the trend in e-commerce of minimising material use and transport volume by opting for paper-based lightweight packaging and mailers made of folding cartonboard or micro-flute, the overall goal being to improve the sustainability of e-commerce business.

Because the surface of these materials is considerably smoother than that of corrugated board, applying 50 to 150 g/m2 of adhesive is more than sufficient to securely seal a box or package. For this application, Baumer hhs has developed the HP 500 SB, a new coating application head that guarantees top quality at application weights up to 150 g/m2. “SB stands for ‘snuff back’ and means that the nozzle closes against the direction of adhesive flow, creating a negative pressure. This in turn has the effect of cutting off the glue flow rapidly and cleanly, preventing any residual tailing from the nozzle”, says Walther, explaining how this innovative technology promotes superior quality when applying pressure-sensitive adhesive in the production of paper-based lightweight packaging and mailers made of folding cartonboard or micro-flute.

Baumer hhs likewise offers an optimised Xmelt hot melt unit for these applications. It has a high-quality flow regulator that adjusts the quantity of adhesive within narrow tolerances when speed changes occur, establishing the basis for high quality gluing. This new gluing system from Baumer hhs is rounded out by a mount with precision settings for accurately adjusting the position of the nozzle relative to the packaging material. This, too, is a key factor for achieving maximum quality in the gluing step. “At CCE International, we will be addressing how important flexible mounts with precision settings are for the quality of adhesive application. It’s an issue that has been underestimated all too frequently in the past.”

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.