ISRA VISION - Inspection System Efficiently Raises Productivity and Quality

Press release from the issuing company

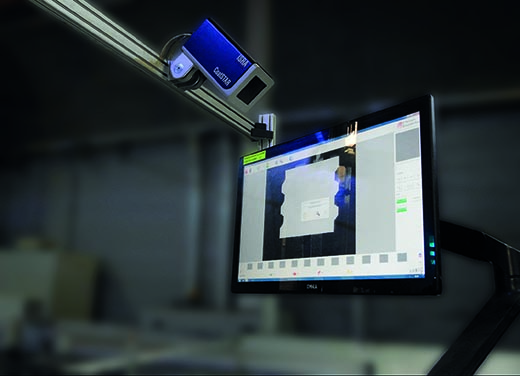

Cinbal, a leading Brazilian producer of metal packaging, has invested in automated quality assurance through ISRA VISION inspection systems. The CoatSTAR system is used to check coated metal sheets for printing defects and ensures their correct alignment on the conveyor belt in production.

Everything from a single source: 100% inspection of raw material and print decorations in high-quality metal packaging

Cinbal is one of the largest manufacturers of printed metal packaging in Latin America. The business volume is growing, particularly with consumers from the food industry, yet increasing price pressures in this highly competitive market are shrinking profit margins. In such a situation, it is particularly critical when additional production errors occur that cause costly scrap. Hence, Cinbal decided to invest in an automatic inspection system in order to improve process monitoring and guarantee continuously high quality to meet its customer demands. When choosing an inspection system, the company opted for the world-leading provider ISRA VISION and its two proven inspection solutions – CoatSTAR for 100% inspection of coated sheets before printing and DecoSTAR, the system for 100% print inspection of metal sheets.

The printshop experts at Cinbal faced a problem that older automatic inspection systems on some of their printing presses did not work as reliably as Cinbal required. . The company, therefore, relied on manual inspection by its press operators. Another problem was that defects not only occurred during the decoration process but often while processing the raw material as well. Consequently, Cinbal needed reliable quality control for all relevant processing steps. As a result, the company placed its trust in ISRA VISION, a manufacturer that offers all inspection solutions from a single source with the automatic CoatSTAR inspection systems for coated sheets and DecoSTAR for metal decorations.

Paint inspection as early as raw material processing

The CoatSTAR inline inspection system inspects coated metal sheets and thus identifies and rejects defective sheets as early as the raw material processing stage. After all, a perfect result can only be achieved if the utilized material is 100% free from defects. Since defective material does not reach the printing process, production costs are sustainably reduced, and the throughput of defect-free products is substantially increased.

To improve the workflow, CoatSTAR collects and documents information on the coating quality, weld seam areas, and dimensions throughout the entire production process. The collected data is used for internal process analysis and also serves as proof of quality for the customer. A new “Advanced Sheet Movement Compensation” algorithm is particularly useful here: It enables the inspection system to exclude false defects during the movement of metal sheets that were previously highlighted during the inspection. Due to the speed of production on the conveyor belts, the sheets can sometimes bend slightly. This material can still be processed without difficulty, where historically sheets were wrongly rejected from the production process. The new algorithm reliably detects these false defects, enabling production to continue without any interruptions and avoiding the unnecessary rejection of expensive metal sheets.

Fast integration into the production process

The press operators adopted the new inspection system quickly. Moreover, Cinbal decided on training additional company employees to use the system and to raise awareness of surface inspection. To this end, an application technology group was set up in the company that trained staff to act as ambassadors and multipliers for the ISRA VISION technology.

Thanks to its compact design and its enormous flexibility, the CoatSTAR inspection system can be integrated into virtually any machine. Likewise, it was seamlessly integrated into the production process at Cinbal and impressed with its fast return on investment. The system even reliably detects deviating color shades on metal sheets coated with transparent paints. The automatic system for rejecting non-compliant sheets enabled the quality in this area to increase considerably. A further positive effect is that employees who previously were occupied with time-consuming inspection work can now perform other important tasks in the printshop.

Perfect print quality for metal sheets

As a manufacturer with a rich history of printed metal packaging, Cinbal is a leading supplier for longstanding customers from the food packaging market... Alongside speed and flexibility, these clients expect their print jobs to free of defects. . This prompted Cinbal to make an additional investment in an automatic inspection system for printed metal decorations, thus guaranteeing end-to-end defect control.

The DecoSTAR inline inspection system now used by the company offers 100% quality control of printed steel and aluminum sheets. The compact system’s highly efficient LED lighting allows it to reliably detect color deviations as well as edge and material defects. Errors in the printed image are recognized immediately, regardless of whether these relate to register accuracy or missing color. The inspection system discovers and clearly classifies even the smallest splashes or streaks on the printed sheets with the greatest accuracy. Furthermore, the early warning of serial defects allows the operator to intervene at an early stage, sustainably reducing waste, lowering production costs and maximizing yield. Alongside inspection, DecoSTAR makes the workflow more efficient thanks to its intuitive multi-touch user interface, which allows the quick and simple configuration of new tasks.

Higher quality confirmed by regular audits

The automatic inspection system improves the operational reliability of the production process. System-generated error reports help Cinbal identify defects more clearly and measure them in order to make decisions when identifying causes. Cinbal has measured and quantified the inspection system's performance by conducting regular audits that include measuring critical deviations. The company observed significant improvements, as the ISRA inspection system allowed the reliable and reproducible detection of registration errors, color deviations, and spots. As a result, the report of non-conformity (RNC) now no longer lists any critical deviations.

From a sales perspective, the ISRA inspection systems used by Cinbal are now promoted as a unique advantage in the marketplace in order to generate benefit for its printing services with an enhanced quality promise.

Summary

With their 100% defect detection, the CoatSTAR and DecoSTAR inspection solutions significantly increase the efficiency of the production process for coated and printed metal packaging. At Cinbal, the realized material and process savings have more than justified the acquisition of the inspection systems, and a quick return on investment has been achieved. With the inspection systems, users strengthen their company’s market position and secure a crucial competitive advantage. Moreover, the systems conserve resources by contributing to the sustainability of Cinbal’s production.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.