Baumer hhs Introduces the FFG go, An Easy-to-Operate Solution Exclusively for Adhesive Applications in Flexo Folder Gluers

Press release from the issuing company

Krefeld – FFG go is the name of a new solution from Baumer hhs designed exclusively for glue application in flexo folder gluers. This latest member of the company’s “go” product line offers simple, intuitive operation, but meets a variety of sophisticated demands on non-contact gluing in the corrugated industry. Developed for applications requiring gluing only, all the “go” products achieve an excellent price/performance ratio. They give customers entry-level access to the world of Baumer hhs and its products, in operation in thousands of systems around the globe, demonstrating their capabilities and reliability every day. The FFG go is a perfect addition to this family.

Baumer hhs, thanks to the high performance of its proven glue application heads, has become the partner of choice for many packaging and machine manufacturers in the global corrugated industry. The FFG go can operate 2-bead application heads based on DLK go technology for simple applications, or a 3-bead configuration based on P-500 technology for more demanding tasks. These multi-application heads can be flexibly adapted to customer requirements and are currently in use in over 1,500 flexo folder gluers around the world, guaranteeing high productivity and quality in continuous operation.

The heart of the system is the Xact FFG go controller, backed by the latest software and hardware technology. Its range of functions is geared entirely to the gluing process—giving customers the option of applying dots or lines. Programming the individual glue beads via the intuitive menu-driven interface couldn’t be easier—or more reliable—for machine operators: All they have to enter on the touchscreen is the top flap dimensions and the flap length. The Xact FFG go also supports gluing on angled or slotted flaps.

With its Glue Save mode, the FFG go further ensures high-level sustainability and cost efficiency. This function converts the system from continuous to intermittent gluing, which can reduce adhesive consumption by up to 50%, without at all compromising the adhesive strength of the glued areas. Low pressure and contact gluing systems cannot incorporate a function of this kind. In other words, the Glue Save mode gives Baumer hhs customers a major advantage over their competitors.

Customers worldwide prefer adhesive application systems from Baumer hhs. In line with the company’s global orientation, machine operators can select one of 30 different languages from the Xact FFG go menu. The controller then shows all displays, help texts and error messages in plain text in the chosen language. In addition, the controller’s memory can store the settings of up to 99 orders. These functions combined guarantee simple operation—and short setup times.

“With the Xact FFG go, machine operators can limit setup to the most essential settings, but they don’t necessarily have to, because the new controller gives them the option of entering any additional settings required for a production order in subsequent menu levels. When it comes to programming glue patterns and parameters, the Xact FFG go basically offers all the functions of our higher-end Xtend range”, says Andreas Schneiders, Corrugated Business Development Manager at Baumer hhs, underlining the flexibility of automated gluing with the FFG go.

Baumer hhs is a pioneer of non-contact gluing with electric heads, a method that offers the corrugated industry a variety of technical and economic advantages. It minimises maintenance and cleaning, and eliminates the risk of glue smearing on the corrugated products. Because the nozzles never touch the surface of the corrugated board, they don’t suffer any wear and tear and dust doesn’t impair their function. Furthermore, the application heads need not be adapted to different material thicknesses. Similarly, the undulating surface structure has no influence on the quality of the application patterns. The beads of glue are applied uniformly every time. Light barriers from Baumer hhs make sure the position of applied glue beads meets standard quality criteria at all speeds.

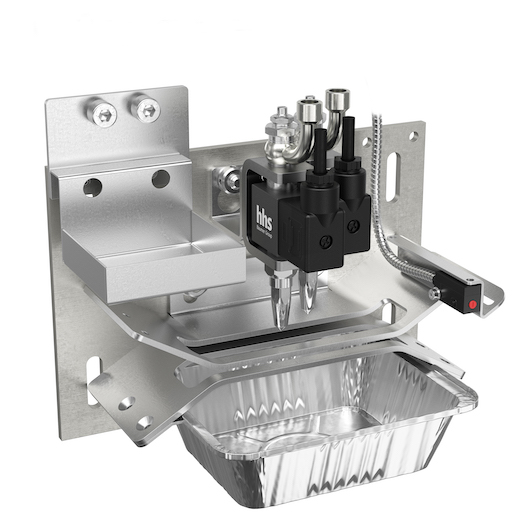

“There’s a persistent rumour in the market that non-contact gluing requires a greater investment than contact gluing. With the FFG go, Baumer hhs provides evidence to the contrary, which becomes even more convincing when you consider the total cost of operating a contact system, including maintenance, cleaning and wear”, says Schneiders, debunking the myth. The FFG go features an innovative automatic cleaning function: before gluing resumes after a brief interruption in production, a minimal amount of glue is ejected into a disposable aluminium or cardboard tray to prevent the nozzles from drying out. The application heads can start reliably applying glue to specifications right away, for instance after a job changeover. In other words, with the FFG go, glue never is dispensed from the nozzles at the wrong angle, never soils the flexo folder gluer, and no blanks pass without being glued. For extended interruptions in production, the application heads can be manually shifted into an optional water bath also from Baumer hhs. It reliably protects the nozzles from drying out for hours.

Baumer hhs supplies the FFG go as a complete package, including a pump with automatic or manual adjustment as an option. The automatically controlled pumps adjust adhesive pressure to the production speed, guaranteeing uniform glue application at all times. The lower-cost, manually set pumps are ideal for production machines with minimal speed variability. The FFG go standard package includes a pump with a maximum adhesive pressure of 30 bar. Pumps suitable for a higher adhesive pressure are also available. They provide a sufficient flow of glue to the application heads even at high production speeds.

“The products, solutions and services from Baumer hhs meet all the demands of industrial gluing. The FFG go, designed exclusively for gluing, gives our customers in the global corrugated industry an added option for their investment decisions—one that stands for maximum quality and reliability in automated gluing.”

The Xact FFG go controller is the heart of the FFG go solution from Baumer hhs for adhesive application in the corrugated industry. Programming the individual glue beads via the new controller’s intuitive menu-driven interface couldn’t be easier—or more reliable—for machine operators.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.