DSM’s New Polypropylene Powder Material Boasts Balance of Properties, Food Contact Approval in Europe

Press release from the issuing company

Geleen, The Netherlands – Royal DSM, a global science-based company in Nutrition, Health and Sustainable Living, today announced the release of Arnilene® AM6002 (P), an expansion of the company’s powder portfolio for additive manufacturing. The polypropylene material is ideal for 3D printing a wide range of applications across multiple industries.

Applications

Manufacturers are looking to utilize additive manufacturing to keep plants running during times of crisis. 3D printing production equipment parts locally helps save time and cost, as well as secure operations to avoid supply chain disruption.

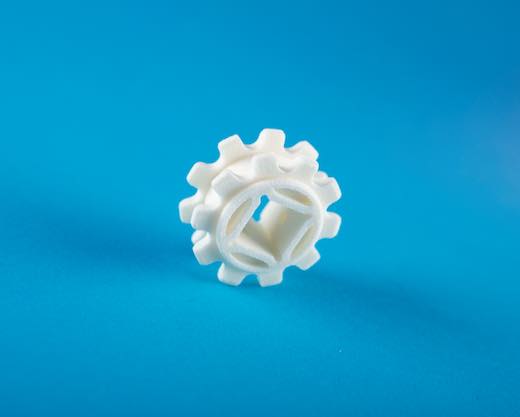

Arnilene® AM6002 (P) has food contact approval in Europe, making it ideal for applications in the food and beverage or nutrition industries, such as conveyor belt guides, sprockets, slides, dosing blocks and creepers. With polypropylene being used extensively in the automotive sector, DSM’s Arnilene® AM6002 (P) is an excellent choice for applications such as dashboard components, interiors and many others in this sector. Additionally, the material is suitable for prototyping polypropylene end-use parts.

Material specifications

To complement DSM’s recent launch of polypropylene for fused granulate fabrication, Arnilene® AM6001 GF (G), Arnilene® AM6002 (P) for powder bed fusion printing is now available to manufacturers looking to utilize 3D printing while also providing a familiar material they are used to handling.

Arnilene® AM6002 (P) offers robust mechanical, chemical and thermal properties, food contact approval in Europe and the ability to print complex designs. This easy-to-process material can be run on existing selective laser sintering platforms. The material is hydrophobic and can be used to print large batches of engineering grade, tough parts without compromising on economics or ease of post processing. Arnilene® AM6002 (P) can be post-processed via automated post-processing, as well as dyeing. With a 90% reuse rate, the material produces less waste, making it a sustainable solution.

Geoff Gardner, Innovations Director Additive Manufacturing at DSM, commented: “We are pleased to further extend material choices for 3D printing with this engineering-grade Arnilene® AM6002 (P) powder. This sustainable material is the type of material that manufacturers across many industries are looking for as they move from traditional manufacturing to additive manufacturing, saving production time and cost, as well as maintaining supply chain performance stability year-round.”

SLS 3D printed conveyer belt sprocket using DSM’s new Arnilene® AM6002 (P)

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.