Finewebtech Increases Production Capacity By More Than 20% With New Nilpeter FA-17

Press release from the issuing company

Finewebtech of South Korea has seen a 20% increase in production capacity following the installation of their new Nilpeter FA-17. The company has already signed on for two additional Nilpeter FA-Line presses to further expand and streamline the business.

Finewebtech was founded in 1987 in the South Korean capital of Seoul. The award winning label and flexible packaging printer primarily deals in cosmetics, household items, foods, pharmaceuticals, and more. After a comprehensive market search, Finewebtech decided to go with the Nilpeter FA-17 midst 2019, which decorated the first All New Nilpeter FA-line installation in the country. According to Erik Blankenstein, Sales Director Nilpeter Asia-Pacific; Nilpeter’s local representation by SCREEN Korea and in particular Mr. Johnny Lee, GA Company & Marketing Director, has played an important role in the Korean market development and business relationship with Finewebtech. The first press was installed in August 2019.

The Confidence to Quote Customers with Shorter Lead Times

“The flexibility on the All New FA has cut our production time significantly,” says Mr. Jang Tae-Soo, President & CEO, Finewebtech Label Solution System.

“For example, having the option to put Rotary Screen on the rail, with its own dedicated UV lamp system, has cut down our preparation time by at least 20% and increased our production capacity by more than 20%. With this, our 9-colour press is working as a 13-colour press as we do not have to compromise print stations to do rotary screen. The ability to put most of the embellishment options on the rail has given our production team the confidence to quote customers with shorter lead times,” he adds.

Print Quality from the All New FA is Uncontested

“Nilpeter’s dedication and development within flexo printing has brought our print quality to an absolute top-level. By keeping the impression and the chill roller separate, print quality from the All New FA is uncontested! Density levels are amazing. The longer web-path on each print station, and even longer web-path at the end for varnish, gives fantastic print and varnish results,” says Mr. Lloyd Jang, General Director, Finewebtech Label Solution System.

”We have many different flexo press brands in-house, and I have to say, the machine downtime on the Nilpeter press is incomparable. And we’ve experienced nothing but quick response times and solutions from the Nilpeter team. When faced with complicated new jobs, the Nilpeter application team is always of great help,” he continues..

Two Additional Nilpeter Presses on the Books

“We have just signed off on our 2nd & 3rd Nilpeter All New FA presses and we are looking forward to further expanding and streamlining our business. We feel very confident that the level of automation, efficiency and flexibility that our additional two FA-lines will bring, will allow us to make this happen,” Mr. Jang Tae-Soo, President & CEO, Finewebtech Label Solution System concludes.

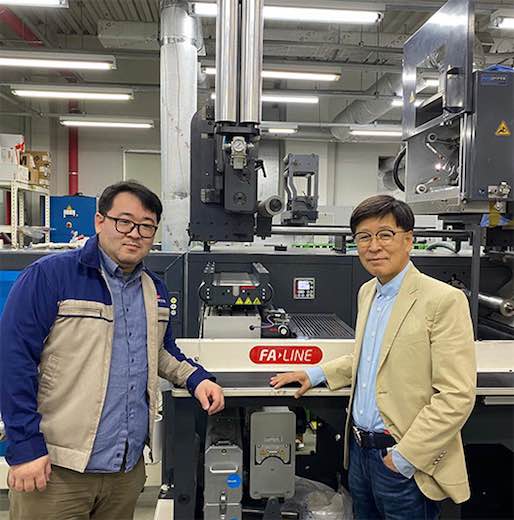

Mr. Jang Tae-Soo, President & CEO, and Mr. Lloyd Jang, General Director, Finewebtech Label Solution System in front of their new Nilpeter FA-17.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.