Luminer Introduces Dedicated Inspection Suite at NJ Labels Manufacturing Facility

Press release from the issuing company

Company inaugurates segregated 7,000-sq-ft space with a new back-number system and its third 100% inspection platform.

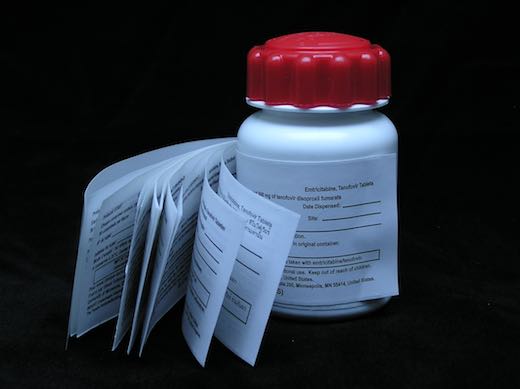

Lakewood, N.J. – Luminer, a labeling solutions provider specializing in extended content labels (ECLs) for pharmaceutical ethical and OTC packaging, clinical trials and various other narrow web applications for the cosmetics, F&B and chemicals sectors, has streamlined its precision product inspection capabilities by introducing a dedicated 7,000-square-foot inspection suite at its primary manufacturing facility in Lakewood, NJ. The quality management segregation also comes with an infrastructure investment: the company has added its third 100% inspection platform, as well as a back-number validation system.

The dedicated space will further improve Luminer’s comprehensive quality management processes. In particular, it is designed to optimize QA/QC oversight for the company’s specialty, extended content labels. Due to their inherently stacked, page-over-page nature, ECLs pose unique inspection challenges requiring niche-specific solutions.

Luminer provides 100% label inspection – a must for its broad set of pharma customers. For ECLs, this entails a complex process that involves, among other extra steps, precision vision systems inspecting individual sheets prior to folding, glue line monitoring to ensure all ECL pages are affixed properly and in correct order, and final inspection initiatives such as thickness monitoring to confirm label-on-label mounting veracity.

Luminer’s addition of a back-number validation system provides additional assurance for pharma customers, by helping to ensure labels are matched to their proper individual packages. Among other benefits, this helps simplify the label application process and, for prescription products, lends to easier compliance with unit-level serialization requirements.

“The new inspection suite helps reinforce Luminer as a medium-sized label manufacturer with big-shop production and quality control capabilities,” said Tom Spina, President & CEO of Luminer. “Extended content labels especially demand a thorough, multi-step inspection process. The dedicated quality management space and new infrastructure will further streamline our workflow, expediting turnaround time from initial quote to production to delivery.”

Luminer recently incorporated a new extended content label production line, a seven-figure investment that doubled its ECL manufacturing capacity. The new line’s exemplary production speeds foster both efficiency and cost-effectiveness, ROIs that Luminer will be able to pass on to customers.

For more information, call (732) 365-3673 or visit www.luminer.com.

- Questions to ask about inkjet for corrugated packaging

- Can Chinese OEMs challenge Western manufacturers?

- The #1 Question When Selling Inkjet

- Integrator perspective on Konica Minolta printheads

- Surfing the Waves of Inkjet

- Kyocera Nixka talks inkjet integration trends

- B2B Customer Tours

- Keeping Inkjet Tickled Pink

© 2024 WhatTheyThink. All Rights Reserved.