- New hardware investments are certainly important, but they won’t realize their potential without an equally upgraded workflow.

- Job onboarding can be a lengthy process that involves taking the customer’s intent, job specifications, substrate requirements, finishing requirements, approval requirements, and delivery requirements through codification to ensure that the job can be executed.

- As we move forward into 2020, your print business planning should include an in-depth review of every touchpoint from the point of sale to the point of delivery.

By Pat McGrew

Introduction

Another year is about to come to an end, and December is a great time for us to look back at what is happening in the world of production workflow. Although a number of new software innovations come to light each year, there is always additional work that can be done. 2019 ushered in new levels of interest in improving and automating workflows, but the level of actual implementation was not as high as we would have hoped to see by now.

What is Hindering Workflow Automation?

Many of us already understand the reasons that the implementation of workflow automation typically falls short of expectations. Some businesses report that the investments in current software solutions aren’t producing the anticipated results. Some cite the costs associated with upgrading their production workflows, often specifying the expense of professional services required to make it work rather than the cost of the software. Others say they are battling more pressing issues in other areas of their businesses, and all of these complaints are valid and understandable. It can be difficult to find the right path when working toward increased workflow automation. We also know that many of these same environments have increased capacity, improved print quality, expanded their product offerings, and grown their businesses by investing in new printing and finishing hardware solutions. As exciting as these new hardware investments are, though, they won’t realize their potential without an equally upgraded workflow.

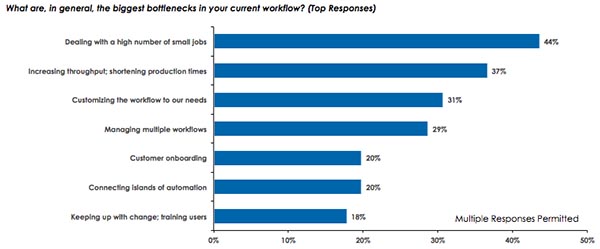

According to Keypoint Intelligence – InfoTrends’ research, the most significant bottlenecks between the sale of a print job and the act of printing of that job exist within the job onboarding and pre-production processes. Some of these steps include dealing with the high number of small jobs that come in and finding ways to increase throughput.

Top Workflow Bottlenecks

N = 101 Total Respondents

Source: NA Software Investment Survey; Keypoint Intelligence – InfoTrends 2018

Job onboarding can be a lengthy process that involves taking the customer’s intent, job specifications, substrate requirements, finishing requirements, approval requirements, and delivery requirements through codification to ensure that the job can be executed as that customer envisions. This means that the specified substrate must be appropriate for the print device, in stock, and available in the quantities required. To accommodate any customer’s requests, the print service provider must dive into the print and finishing specifications to verify that they can be accomplished with the equipment available. The printer must also schedule the job so that it meets the delivery requirements specified on the job order.

Completing the job onboarding process is a tall order, and it often involves multiple people sending many emails and making numerous phone calls while also checking on stocked supplies and chasing jobs that are already in process. This isn’t an effective path to the future. No matter how fast your printing and finishing equipment is, it will never realize its true ROI unless the front end processes have been automated as much as possible.

Planning for the Future

As we move forward into 2020, your print business planning should include an in-depth review of every touchpoint from the point of sale to the point of delivery. How many people touch each job? Is your quoting and estimating solution automated? Is it connected to the supply chain to accurately reflect the price of stock at the time of the quote? These are just some of the data points—there are dozens more. If you don’t set aside time to review your workflow now, you might find future growth to be out of reach. An inefficient workflow can lead to extended print shifts and delays in delivery, even when faster equipment has been installed.

As you review where you are right now, think about your internal production workflow as well as the connectivity to your business workflow. Future-proofing your business also involves ensuring that all work is charged accurately, evaluating change requests against billing options, and controlling discounts so that the quote used by management to control business costs is an accurate reflection of what is billed for the job.

The Bottom Line

For some companies, simply conducting a self-assessment of workflow automation can be enough to get the process going and drive a business transformation. For many others, however, a neutral third party may be required to accomplish an assessment that uncovers bottlenecks and offers sensible recommendations. Keypoint Intelligence – InfoTrends’ Production Workflow experts provide this service, leveraging industry surveys and on-site walk-throughs to provide high-quality feedback on the current state of workflow automation. If you’re unsure about your existing workflow and interested in future-proofing your business, contact ustoday!

Leveraging more than three decades as an evangelist for technology in communication, Keypoint Intelligence – InfoTrends’ Pat McGrew uses her technical and marketing background to lead the industry toward optimized business process and information workflows. She has worked with companies to help them define their five-year plans, audited workflow processes, and developed sales team interventions and education programs. She educates the industry in production workflows to promote effective communication. If you have stories to share, Pat would love to hear from you! She can be reached via Twitter (@PatMcGrew), LinkedIn, or e-mail ([email protected]).