- Through this partnership, Bürkle hopes to commercialize its decorative solutions in the woodworking industry using EFI’s Cubik inkjet printers, Inks, and Fiery workflow suite.

- EFI will be responsible for the full integration of its systems, including sales and maintenance. Meanwhile, Bürkle is responsible for upstream and downstream processes.

- Bürkle plans to create a testing and demo center in Spain that integrates its equipment with EFI’s printing technologies. Clients will be invited to test and develop new applications and processes.

- EFI highlighted several applications at LIGNA 2019, including thermoforming, that represent the full breadth of EFI solutions that can be used in woodworking production.

By Ron Gilboa

Introduction

In the leadup to LIGNA 2019 toward the end of May, EFI announced a partnership with Robert Bürkle GmbH, a surface finishing technology company based on Germany. Through this partnership, Bürkle hopes to commercialize its decorative solutions in the woodworking industry using EFI’s Cubik inkjet printers, Inks, and Fiery workflow suite.

During LIGNA 2019, Ron Gilboa of Keypoint Intelligence – InfoTrends caught up with José Luis Ramón Moreno (Vice President and General Manager of EFI Industrial Printing) and Olaf Rohrbeck (Bürkle Chief Sales Officer and Chief Technology Officer at Ligna) to learn more about this new collaboration. InfoTrends also hoped to gain greater insight into Moreno’s and Rohrbeck’s perspectives on digital printing and other important industry issues. A written transcription of the interview that occurred at LIGNA 2019 is provided below.

Meeting at Bürkle booth (left to right):

Olaf Rohrbeck, Ron Gilboa, and

José Luis Moreno.

Interview Transcription

Ron Gilboa (InfoTrends): We’re grateful for the opportunity to chat with you at LIGNA. This partnership between Bürkle and EFI represents a new industry relationship. What motivated Bürkle to enter the world of digital printing?

Olaf Rohrbeck (Bürkle): As you know, Bürkle has been an industry pioneer since 2006 or 2007. We’ve been a part of the LIGNA event ever since Bürkle’s digital printing partnership with Durst. That partnership was ongoing until 2012, when the management decided to invest more heavily in solar technology and not as much in core businesses. When I came to Bürkle in 2014, we ended the corporation contract with Durst and re-focused our business on its core elements using a “back to the roots” tagline. We began concentrating on developing a blueprint for our core business, and I’d estimate that this initiative was ongoing until 2017.

As time went on, we were receiving more and more demands related to digital printing. We have a small footprint in the United States in the display graphics areas. Our customers started asking about Bürkle’s digital printing offerings. We’ve seen a number of innovations in this space from businesses like Barberan, Cefla, Durst, and Hymman, but we were no longer contracted with any of these companies. That’s when we knew that we needed to find some new partners. Sometimes in life and in business, you get lucky…and that’s what happened to us. We met EFI in Valencia when the company announced its acquisition of Cretaprint, and the time just seemed right for both of us. EFI wanted to enter the woodworking market, and we at Bürkle were looking to expand our digital printing know-how. We started doing business together.

From the very first moment, all of the discussions that we had with EFI were very constructive. We had a chance to visit EFI in its Valencia facility and soon came to understand that the technology is outstanding because they offer the ink technology software on board. EFI has a new Research & Development department, and its Cubik S1800 is a fantastic device. From the start, we were very clear that we didn’t want to make the same mistakes that we’d made in the past. This meant that we wanted EFI to be responsible for the full integration of its systems, including sales and maintenance. Meanwhile, those of us at Bürkle are responsible for upstream and downstream processes. This is going to be our new mode of operation after LIGNA. I was so excited to see the activity at our stand during the show—the response from the market has been unbelievably positive!

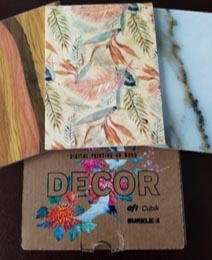

EFI’s Cubik on display at Bürkle’s booth during LIGNA 2019.

You might be wondering what the next step for Bürkle will be. We’ve decided to create a testing and demo center in Spain that integrates Bürkle’s equipment with EFI’s printing technologies. We’ll invite our clients to test and develop new applications and processes. The development of this center will occur in stages over the next one or two years.

Ron Gilboa (InfoTrends): Now let’s move to the EFI side. We’ve already seen proven technologies in multiple segments, including ceramics, textiles, sign and display, and now woodworking. What makes EFI’s technology unique in relation to that of its competitors? How much of EFI’s technologies and knowledge can be applied to the woodworking segment?

José Luis Ramón Moreno (EFI): Well, that's a very interesting question. In the past few months, we’ve conducted several internal summits to review our go-to-market strategy. Although EFI’s team members are experts in a number of technological areas, woodworking is not one of them. Instead, we have a broader expertise in the many segments of digital printing. Partnering with Bürkle was complementary for us because its staff members really understand the woodworking industry and its multiple segments. Through our partnership, Bürkle can serve as a bridge to what makes sense for a unique area like woodworking. For our part, we can bring greater value to Bürkle’s customers as well as the industry at large. Our first collaborative product line will soon be ready to go, and of course we’ve got a longer-term strategy on our road map as well. When we’re lucky enough to partner with companies that already have industry know-how, we’re better positioned to integrate new technologies into our business and move fast in a very competitive landscape. Some of our solutions are almost completely ready, so Bürkle and EFI have been able to make an impact on the industry in less than a year.

So far, we have mastered digital printing as a key component of our new offerings, but a full solution will require further investments in ancillary pieces of equipment. This is the strength that Bürkle brings to the table. EFI is very happy about how this partnership has unfolded over the past few months. There is a lot of intensity on both sides to bring a solution to market in a way that make the result greater than the sum of its parts, and that’s how it should be!

Ron Gilboa (InfoTrends): EFI announced plans to introduce its new Cubik S1800 and water-based mineral ink at LIGNA. Tell me a little about that.

José Luis Ramón Moreno (EFI): Yes…we ultimately decided to move to a joint booth that was closer to Bürkle’s space so we could create a branding umbrella of sorts. We have two technologies on display at the show, UV and LED single-pass, and we are also demonstrating mineral ink that is water-based and compatible with multiple substrates.

Mineral ink print samples produced on EFI’s Cubik.

Ron Gilboa (InfoTrends): You say this mineral ink is compatible with a number of substrates. Are you thinking about digital staining?

José Luis Ramón Moreno (EFI):That’s the idea. Of course, we also have all of our core EFI technologies, including color management, workflow solutions, ink chemistry, and manufacturing capabilities. We collaborated with Bürkle during LIGNA in a joint booth to demonstrate real solutions for the industry in action. Although we don’t have our EFI VUTEk multi-pass equipment on display at the show, we are highlighting a number of applications, including thermoforming, that represent the full breadth of EFI solutions that can be used in woodworking production.

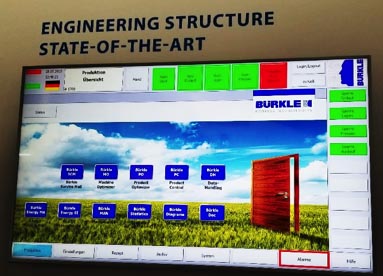

Ron Gilboa (InfoTrends): Our industry is also embracing the topic of Industry 4.0. Supporting interconnectivity between applications is becoming more important, so we’ve seen solutions using Digital Twin technologies to create digitally simulated scenarios before final implementation of manufacturing lines. In Bürkle's booth at LIGNA, I noticed that Digital Twin technology was being used to create commissioning scenarios. The solution was also being demonstrated for production tracking. Does Bürkle expect the EFI Cubik to become one of the resources for planned Digital Twin simulations, so customers can have an up-front idea of how their system will operate in real life?

Olaf Rohrbeck (Bürkle): Under the Industry 4.0 umbrella, Bürkle is following a road map and implementation strategy that encompasses the entire company. Industry 4.0 is a highway with a multitude of components that need to be implemented, and one of these is Digital Twin. Digital Twin is used by our planning department and, eventually, these plans will join the physical world via the use of mechatronics. In fact, Bürkle recently merged these two departments into one. With our design architecture based on Siemens control, the digital and physical can be in full synchronization.

Bürkle’s Industry 4.0 user production dashboard.

As a key Siemens partner, we conducted several pilot project programs using their Digital Twin solutions, which we are introducing at LIGNA. This solution is used to commission woodworking solutions before they are installed on the production floor. This will reduce risks and lower the time to productivity. It will also create a “win-win” situation for us and the client, and this is only one of the directions that we’re following. The second one will tie in these reporting capabilities to be used in preventive maintenance. With sensors in the machines, we can track production and avoid a catastrophic breakdown. Intelligent algorithms are added to the software so customers can monitor their equipment. For example, if a printing head goes down, we can alert the operator using a production dashboard. We will also be developing these solutions for our joint manufacturing lines.

Ron Gilboa (InfoTrends): One more aspect of EFI’s capabilities is its knowledge in proofing paper samples of the final production. This can be a critical tool in demonstrating the basic design to architects before raw materials are used for production. How do EFI and Bürkle plan to address these capabilities as you develop awareness in the influencer community?

José Luis Ramón Moreno (EFI): We’re currently focusing on the early adopters who are already using this technology, so we’re not yet ready to promote these integrated solutions to the influencer community. That said, this set of tools is available to us to help customers accelerate the time to market, as well as collaborate between producers and the creative community. All of this is still very new, and a lot of the interactions that we’ve conducted over the past few days are helping us understand customers’ needs. We’re working to create an active dialogue where our customers learn about what digital printing can do for their businesses in terms of creativity, time to market, and other efficiencies. It's all super exciting!

Ron Gilboa (InfoTrends): Well, thank you both for spending few minutes with us to discuss the existing news from Bürkle and EFI at LIGNA 2019. We are all looking forward to seeing what comes next!

As Group Director at Keypoint Intelligence—InfoTrends, Ron Gilboa is responsible for a team of seasoned professionals covering industry segments including print on demand, packaging, wide format printing, industrial printing, and production workflow. He conducts market research, market forecasts, custom consulting projects, and strategy and planning engagements. Ron has been involved in the graphic arts, publishing and industrial printing industries since 1980.