- The theme of this year’s event was Success with Automation, and the concept of automation was featured widely across the two halls.

- Agilox, an Intelligent Guided Vehicle (IGV) from AGILOX Services of Germany, moved print during the event. Agilox followed programmed instructions to make pickups and deliveries between vendor stands.

- In a trade show setting, there are many more people moving in random directions without the regularity that is normal in a typical print shop, but the Agilox IGV at Hunkeler Innovationdays was able to navigate the floor and do its job.

By Pat McGrew

Introduction

During odd-numbered years in February, the digital printing industry looks toward Luzern, Switzerland, for the Hunkeler-sponsored Innovationdays event featuring finishing solutions for the transactional, commercial graphic arts, and book industries. Innovation is the place to be seen for digital print hardware providers, and it’s a place to have meaningful conversations for those offering auxiliary solutions, software, and paper. Print service providers from around the world come to Hunkeler Innovationdays with a shopping list and checkbook, and for good reason!

This Year’s Theme: Success with Automation

The theme of this year’s event was Success with Automation, and the concept of automation was featured widely across the two halls. Although the coming weeks will likely bring many articles and videos discussing the details of the announcements and the innovations on display from the Hunkeler team and its partners, there were some stories out of the mainstream that enhanced the event.

Starting with the basics, the Who’s Who of printing hardware brought their presses to supply rolls of printed paper that would then be finished throughout the halls. Big names like Canon, HP, Konica Minolta, Nipson, Ricoh, RISO, Screen, Xeikon, and Xerox all showcased their very capable digital presses, and print enhancement devices from companies like Scodix and MGI Solutions were on display to truly take print beyond CYMK.

The rolls and sheets of paper were used to demonstrate a wide variety of finishing capabilities, including punching, perfing, and folding to full bookbinding lines. In earlier editions of Innovationdays, moving the materials across the floor during the show proved to be quite a challenge. This year, Hunkeler had an innovative piece of equipment on the show floor to automate the process and provide help.

Introducing Agilox

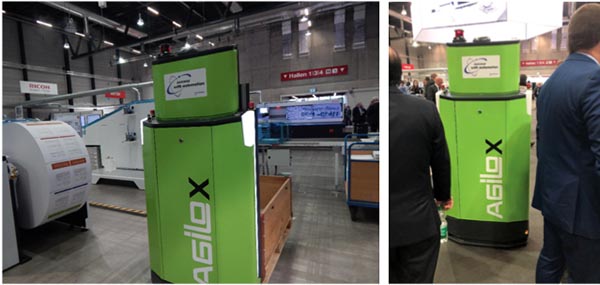

In keeping with this year’s Success with Automation theme, Hunkeler brought Agilox, an Intelligent Guided Vehicle (IGV) from AGILOX Services of Germany, to the event. Serving as a Sherpa for moving print, Agilox moved gracefully across the show floor. In addition to keeping a respectful distance from the human population, Agilox followed programmed instructions to make pickups and deliveries between vendor stands. Teams of Agilox IGVs can work together to keep materials moving from a warehouse to a shop floor, and from a shop floor to shipping. As the printing industry seeks more and more efficiency, IGVs like Agilox can become part of the production floor workflow to free people from tedious tasks.

Agilox at Hunkeler Innovation Days 2019. Photo by Pat McGrew

One of the most interesting things about IGVs is that people tend to give them space. Paper-moving robots are not uncommon in European print shops; workers soon develop a sense of where the robots are and how they move. In a trade show setting, there are many more people moving in random directions without the regularity that is normal in a typical print shop, but the Agilox IGV at Hunkeler Innovationdays was able to navigate the floor and do its job. Price points for IGVs have been coming down even as the intelligence that can be programmed in continues to expand, so the Agilox example is an interesting element as we all continue on the path toward success with automation.

The Bottom Line

The next drupa event in Dusseldorf is fast approaching—we’re now only 15 months out! The hardware and software vendors who practiced their talk tracks for Hunkeler Innovationdays have some work to do before heading out to drupa in June 2020. This upcoming event might very well become the Automation drupa. If this proves true, the ability to speak about automation within machines, between machines, and within the infrastructure workflow that is the framework of end-to-end print production will be essential. If you need help preparing your talk track for the next drupa event, Keypoint Intelligence – InfoTrends can help!

Leveraging more than three decades as an evangelist for technology in communication, Keypoint Intelligence – InfoTrends’ Pat McGrew uses her technical and marketing background to lead the industry toward optimized business process and information workflows. She has worked with companies to help them define their five-year plans, audited workflow processes, and developed sales team interventions and education programs. She educates the industry in production workflows to promote effective communication. If you have stories to share, Pat would love to hear from you! She can be reached via Twitter (@PatMcGrew), LinkedIn, or e-mail ([email protected]). For more information on how to gain access to InfoTrends’ content or to subscribe to our consulting services, contact Deanna Flanick at [email protected].