- Most commonly, printers cite the inability to cost-justify the investment or being uncertain of the benefits as top reasons for not implementing a greater degree of automation.

- According to InfoTrends’ European research, average annual labor costs for 12 identified workflow tasks surpass €1.4 million.

- If you’re looking for ideas on how to get started, identify a specific, addressable point of automation that can be a quick win.

By Ryan McAbee

Introduction

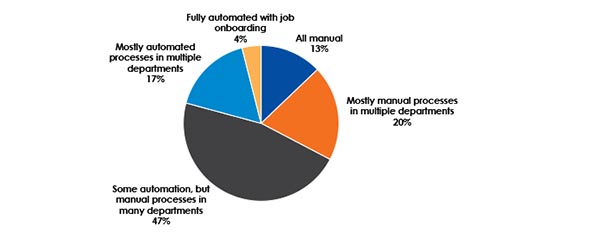

Most printers will readily admit if they’re struggling with their workflow, and they’ll specify the areas, too. According to Keypoint Intelligence – InfoTrends’ 2018 North American Software Investment Outlook, 44% of printers reported that dealing with a high number of small jobs was their biggest workflow bottleneck. At the same time, however, only 4% of these printers had fully automated processes that offered job onboarding. The greatest percentage of respondents stated that their workflow processes were partially automated but remained manual in many departments.

Figure 1. Which of the following best describes the level of automation with your workflow processes?

Base: Total Respondents in North America

Source: North American Software Investment Outlook; Keypoint Intelligence – InfoTrends 2018

Barriers to Automation

If printers recognize this business challenge, why have they not put more automation in place to aid employees and benefit customers? In the course of its survey work, InfoTrends has posed this question multiple times to printers using various types of software. Most commonly, these printers cite the inability to cost-justify the investment or being unconvinced/uncertain of the benefits as top reasons for not implementing a greater degree of automation. The cost justification component may be the key to unlocking this mystery, as it is hard to justify the expense of software implementations if you aren’t fully aware of the labor and process costs that will be incurred from doing the work.

For 2019, InfoTrends has set out to discover the labor costs and more metrics associated with twelve workflow tasks required for many types of print jobs. Those workflow tasks are as follows:

|

Artwork and Design |

File Corrections for Content |

Hard Copy Proofing |

|

Document Scanning |

File Corrections for Artwork/Color |

Data Preparation for VDP |

|

File Retrieval & Job Onboarding |

Imposition |

VDP Document Design |

|

Preflighting |

Electronic Proofing |

VDP Logic Programming |

The results from our 2019 European Software Investment Outlook are already in, and the North American version will be launching soon with publication anticipated in April. According to our European research, average annual labor costs for all twelve of the workflow tasks outlined above surpass €1.4 million. The three tasks with the highest average annual labor costs included artwork and design, data preparation for VDP, and preflighting.

Quick Wins

There are many paths toward automating your print workflows, and not all of them require huge investments or long implementation times. If you’re looking for ideas on how to get started, my suggestion would be to identify a specific, addressable point of automation that can be a quick win. Trying to automate your entire workflow often leads to information and decision paralysis—you start out with all the best intentions, but you become overwhelmed and nothing gets done in the end. Here are three quick wins that are affordable, easy to implement, and can provide immediate improvement:

- Stop accepting customer files through e-mail and FTP! Switch to tools that provide online file submission methods that can also push those files to the next workflow step, typically preflighting.

- Stop inspecting files manually using a checklist, or even a preflight tool that requires a person to open the file and click a button. Instead, use an automated preflight solution that processes files as they hit a hot folder or can be scripted via API calls.

- Stop manually creating impositions or tweaking premade imposition templates…and if you are still imposing in a creative layout program, stop that immediately! Find a smart imposition tool that can create dynamic, even combo/ganged, impositions using data from a spreadsheet or your print MIS and information about your equipment mix.

The Bottom Line

What should print shop owners, managers, and other staff members do with this information? Start by auditing your current workflow processes to establish a baseline for what tasks are performed, by whom, and with what technology. This type of assessment is often eye-opening; the reality of what is occurring is typically far from the expected or ideal. It also increases the communication and understanding between management and staff, as well as between departments who can then work together to make improvements.

A workflow assessment will provide insight into the workflow areas that will have the biggest impact (or return on value) and cause the least disruption. As noted earlier, there are several types of software solutions that can provide “easy wins” and a quick payback. Just get started!

Ryan McAbee is a Director for Keypoint Intelligence – InfoTrends' Production Workflow Consulting Service, which focuses on providing technology, business, and market insights to clients in the Digital Marketing & Media and Production Workflow markets. In this role, he is responsible for conducting market research, market analysis and forecasting, content development, industry training, and consulting with print service providers.