Even in the industry's most profitable and growing years, the mantra “there's too much capacity in the industry” was always heard. It's been a misplaced and inaccurate portrayal of the business, yet it persists.

What is the easiest way to increase capacity utilization? Simple: keep old and inefficient equipment in use. It will always be busier than new equipment, you'll never make money, but your utilization will always be high. It also assumes that prices and profits are solely dependent on production capability. I wrote about this in 2004 and also in 2010.

Data are paradoxical: there are numerous instances where utilization was low and profits were high. Why? The calculation does not reflect the unit costs of goods (not all equipment is the same), the selling prices of output (some printed goods are more profitable than others), or the effects of wise management or skillful workers. The quality control movement of the 1980s taught us how important that is; skillful workers can reduce unproductive utilization and increase profits.

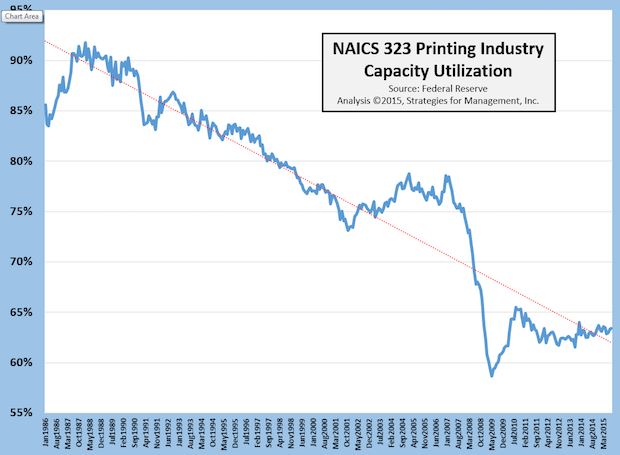

Data for the chart come from the Federal Reserve and are published monthly. The biggest drop in utilization was in the 1980s, when the value of printed goods rose because of cost reductions from digital prepress and the growth of process color printing, which had greater ROI than black and white. So profits were good even though utilization was going down. The calculation of breakeven for individual equipment, departments, and the entire business are much more important than that of capacity utilization. What's even more important? Making your clients more productive and profitable because of what your company does for them.