1

Failure to See Print Software as a Critical Infrastructure Investment

When print was king, all you had to do was keep investing in new production equipment and have good customer service. Now that print has some serious digital alternatives to communication, the landscape has changed. Print software in all its forms (web-to-print, Print MIS, pre-press tools, production automation, CMS, CRM, etc.) is now part of your infrastructure spend. You can’t produce print without a building and presses; you can’t successfully compete in the modern economy without a solid software infrastructure. Your investment and implementation of print software has tremendous influence on your overall business success. Nothing about software is “nice to have” anymore, it is as important as your print production equipment. Successful printers are studying software, becoming experts in the same way they studied presses.

2

Still Believe Print Manufacturing is Your Differentiator

The print manufacturing process has evolved to the point that many competitors can create similar quality. The differentiation is not in your printed piece, it’s in how you sell, how you go-to-market, and how you solve customer challenges leveraging software technology.

3

Refusal to See that Print Software is Required to Reach Customers

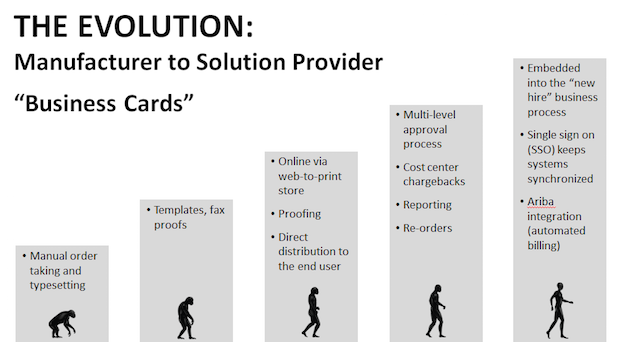

Customers want convenience. This goes beyond self-service into embedding the offer for print inside the customer’s business process. We have been printing business cards for a long time; the evolution of the business card is more about how the customer buys it and less about how it’s manufactured. This evolution is enabled by software and human resources in your organization that have the technical skills to embed the offer for print in the customer’s business process.

4

Lack of Internal Print Software Expertise

We would never run our print business without a press operator, yet many print businesses are currently operated without any technical resources (internal or external). Software is something you have to invest in both in purchasing and having the resources to properly care and feed it.

No matter what the technology vendors say, print software takes labor to manage, maintain, and continually evolve with your business.

5

Buying Software is the Easy Part

Most print software is purchased and then only partially implemented. The reasons are diverse, the frustrations are high, and the finger pointing is extensive. The purchase of software doesn’t solve any of your challenges. Proper implementation of software to fit the unique needs of your business is where all the ROI happens. Print software implementation is often left to the vendors; they know only one side of the equation (their software). A successful implementation requires two sides coming together 1) knowledge of your business, 2) knowledge of the print software solution. This requires at least two parties; you and your vendor. My biggest frustration is that most print software vendors focus on training during the implementation phase instead of doing. Most software implementations take a tremendous one-time effort to implement, why do you spend so much time training me how to do something that I’ll do exactly once? Why not just do it for me and teach me how to edit, maintain, customize, and iterate after the software is up and running? A massive dose of training upfront is usually wasted because it is focused on a very small resource pool (sometimes a single person) and nobody can retain that much knowledge in a short period of time.

Get the software implemented then teach me how to drive it once it’s running. I don’t want to know how to build the car (some Print MIS installations feel this complicated); I just want to be able to drive it.

Discussion

By Bill Knepper on Jun 24, 2015

Amen to all of the above!!!!!!!!!!

By Jennifer Matt on Jun 24, 2015

Bill,

We are in the middle of a very big transition in our industry. We have made it through big transitions before (desktop publishing, digital printing, etc.)

The transition is often messy and crossing that divide between how its always worked and the new realities can be uncomfortable.

I don't think there's an option here, all the trends are pointing to a more connected, more informed buyer, who needs partners instead of vendors, and to reach them you need to leverage technology.

I'm confident that those printers who engage with software as part of their infrastructure investment will survive and thrive on the other side of this.

Jen

By Gerald Walsh on Jun 24, 2015

You may not want to know how the car is built, but you definitely want to know what happens when you push that red button!

Jennifer makes the point that proper implementation is where the ROI happens. She's absolutely right and I would go further to say that (1) selection of a management system should include an analysis of the process necessary to implement and (2) the selection of the implementation team is almost as important as the selection of the system itself.

One of the biggest pain points in the implementation of a management system is the "We've always done it this way" syndrome and if the person or team responsible for the implementation of the system is not fully versed (and immersed) in why your business has selected a new system, their implementation goals will be different and your opportunity for success will be greatly diminished.

Ask Udi Arieli at EFI (developer of the Theory of Global Optimization or TGO) - he'll tell you that the global optimization of a printing business requires the right people, process and plan. You may not need to know how the car is built, but you definitely want to know how a decision you make during implementation will impact global performance. A good decision can eliminate thousands of touches, improve accuracy and reduce waste while a bad decision can eliminate process and profit potential before you've entered your first job.

By Jennifer Matt on Jun 24, 2015

Gerald

Thanks for building on the ideas - very helpful. We often get put right into the middle (between the printer and the vendor of the Print MIS). And we often get brought in when things have gone "off the rails".

Because we're brought in by the printer, we often listen to lots of frustration with the software and the vendor. Nobody's perfect and Print MIS implementations are a very challenging project for any company. Your points are right on - the printer has to have resources and a vision for how they want their business to run post-implementation.

Here's what we all want to avoid:

1) Moving bad data and bad processes from their legacy Print MIS to their new one (total missed opportunity to re-define your business based on the current realities and a powerful new system)

2) Implementing a 'generic' version of the Print MIS that doesn't really meet the needs of your print business. This will lead to low adoption by your people, lots of frustration and worst case scenarios like starting to develop processes outside the system (Excel, post-it notes, napkins, white boards, and writing on your hands ;-)

3) You partially implement the new solution and then dump it and go back or just stay in a state of limbo of messiness. Yuck. You spent bucks on the new system, you diverted resources, you disrupted the flow of your business - for what?

Get your vision and your resources lined up (it takes more thought and more effort than you think to do it well but its WORTH IT). A beautiful Print MIS implementation is a marriage between the software provided by the vendor and your business vision.

Printers need to be data-driven. This requires a trusted system of record. The proper implementation of your Print MIS sets the data-driven foundation for almost every decision you make moving forward.

Jen

By Jane Mugford on Jun 24, 2015

Gerald you are so right that one of the biggest pain points is the "we've always done it this way" syndrome. In fact, I would go so far as to say it's not just a pain point but it can completely derail an implementation. If people really wanted to run their Print MIS the way they always have, they would never bother to invest in new technology. However, human beings are creatures of habit and it often makes the "initial" implementation feel easier if we attempt to clone what we have always done. However, that quickly makes the new technology feel like a failure because the new print MIS system is put in to a "garbage-in, garbage-out" situation. When we encounter this (which is quite often), this is how we try to coach printers in to rethinking their implementation approach:

1) What if there was no time barrier?

Most often the reason printers end up trying to replicate their current processes and legacy data in a new Print MIS is due to lack of time. They have the best of intentions but after the purchase is done, the pressure to get the system implemented is extreme. Something has got to give and usually it's taking time to rethink how your new print MIS should work FOR you. People immediately start cutting corners due to lack of time and start skipping critical points like evaluating data structure and process improvement opportunities etc. Having a conversation around 'if there were no time barriers' often leads to some very constructive conversations around doing things differently and committing to investing time to improve processes and data structures.

2) Will how you plan to set this up work for you 2 years from now?

This is a very telling conversation and usually the admission is that 'no, we might have to re-work this down the road' often comes up. I cannot tell you how many times we get called in to 're-implement' aspects of an implementation 18-24 months post go-live. I have three projects right now that are re-implementations with the printers of each openly admitting they should have taken more time up front to implement properly in the first place. It's just like production rework. People always feel rushed to get a job out the door in the first place skipping quality checks, but they always find time to do the re-work properly. It ends up taking a lot more time and costing a lot more money.

3) What would wild success look like?

This is one of Jennifer's favorite questions to ask and I also ask it all the time now. When people are asked that question they get excited, creative and energized rather than feeling overwhelmed. People then start to fight for some of the 'wild success' elements rather than sticking with the "we've always done it this way".

Implementing a new Print MIS system is just about the hardest thing a printer can do, but it has the biggest potential for increasing profit within your company. It is really worth considering whether you want to burden it with the "we've always done it this way" syndrome.

By Robert Godwin on Jun 24, 2015

"We've Always Done It This Way" and the Human Condition

Anyone who has had the role of Change Agent in an organization has heard this excited utterance. It is the first line of defense for those responsible for producing results.

It took me a while to understand what was really being communicated: "I depend on a system I know and the information I use from it."

Change Agents need their own Hippocratic Oath along the lines of "First, do no harm". It is prudent to transition methodically and bring the stakeholders along at an acceptable pace.

The legacy methods yielded results and need to be addressed so that the new workflows and practices deliver the results and useful data those stakeholders require. This assurance should be at the forefront of introducing change. The efficiencies of a well implemented MIS are then less of a threat, and more readily perceived as a benefit.

No change is easy. Everyone hates street repair and the detours that go with it. And nobody likes rough pavement and potholes. Are we humans ever going to know happiness? Perception drives the resistance to the changes, the same changes that inevitably spawn the cry “We’ve Always Done it This Way”.

By Brady Manthe on Jun 24, 2015

As someone responsible for change, I have had to take an honest look in the mirror. As a bit of reference, I was hired to make changes and was forewarned that "everyone would resist change". What I have found is completely the opposite. Everyone realizes that changes are part of the landscape today and look to investments and improvements to remain competitive. What people won't tolerate, and shouldn't, is a horrible implementation of the proposed changes. If your a leader in your organization that is trying to implement changes, ask yourself if you are meeting resistance because of the assumed human nature to resist change, or is the implementation just mishandled. I suspect if you're honest in your assessment you will find it's more often the latter. I think the human nature to resist change is often an excuse for why a mishandled implementation met resistance.

By Corry Casler on Jun 25, 2015

#5 Love!!!

By Jennifer Matt on Jun 25, 2015

Brady,

I think one of the most common mistakes with large scale changes is assumptions made about how much your people care and how interested they are:

Not enough context is provided for the initiative - people who are asked to change want to know "why?" and then specifically how this change is going to impact them.

When you deliver the context its prudent to talk about the overall business goals THEN you have to take the time to translate the change to each functional area in your business.

For Print MIS implementations we like to ask questions of each area (e.g. shipping, bindery, pre-press) like "when you come in each day, where do you go to see what your day looks like?

You engage with the individual in their role and then you say, "what if everything that needed to be shipped that day appeared on one screen in the order in which you need to act on it? How would that change your day? What if when jobs came out of finishing/bindery you were alerted that they are ready to be acted upon in shipping?

This helps them understand how their specific jobs will be easier when the new system is fully implemented.

Ask then what else could the system do to make you more efficient?

Then you have to do the MOST important thing - ask them what they could do for the company with the extra time they will have due to this increased efficiency. This will get them thinking about all the things they would like to improve but don't have time to improve because they are bogged down in inefficient daily processes.

Jen

Discussion

Only verified members can comment.