In Q3, 2012 I.T. Strategies surveyed Wide Format Print Converters and buyers in the US to gauge output-selling price for wide format printed output. We excluded billboard output and super-large format display graphics, which has highly variable drivers regionally. We interviewed over twenty-five converters and buyers in order to cover the spectrum of wide format output offerings. Each resource represented a different perspective on the selling price of wide-format output. We interviewed sellers and buyers of output produced on low-end, high-end, flat-bed and roll to roll printers, and all ink chemistries-UV, solvent, eco solvent, and latex to get a sense of current retail output prices.

Interviewee's responded with retail output selling from $0.38 up to $6.00 a square foot, depending on substrate and many other variables. However, the most common response was almost always, "it depends". We know there are a lot of factors that go into pricing for digitally printed output. It is not as simple as, "the cost to print, plus X% mark-up" equals "$X per square foot". Of course the printer's cost is considered when quoting a sell price, but there are different cost models within equipment categories and ink chemistries. For example, newer equipment is often more efficient than older hardware, so the job spends less time on press, which reduces the cost and therefore selling price is more competitive. Another example: two converters, who purchased the same printer model, may have much different leasing and/or ink cost which affect their cost and in turn, affect the sell price.

Determining Price

How does a converter determine sell price of printed output? Many converters use an "hourly press rate" as a starting point for quoting a sell price. This rate encompasses all costs to run the printer for an hour-including hardware, ink, labor, rent, electricity, etc. A Converter can enter all of these individual cost equations into an MIS software program, and then automatically generate quotes based on the parameters of each job against the allocated cost per hour. Many converters do not use an MIS system, instead they have customized their own quoting system or maybe use an internally developed spreadsheet or just have an hourly cost calculation in their head. Using an hourly rate ensures that all of the converter's costs are covered in the sell price, if all overhead is included and actual costs are correctly assigned. The hourly cost ranges are based on overhead and what values the converter assigns to each component (i.e. do they amortize hardware over two or five years, for example?).

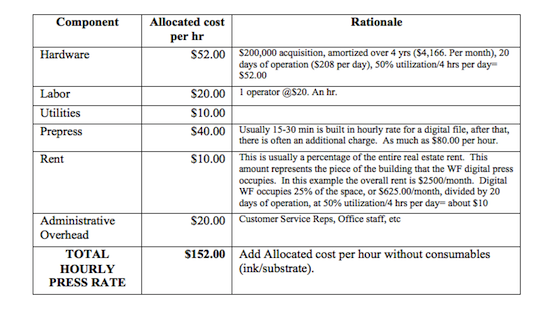

Here's a simple example of how a converter may come up with an hourly rate for his press: Let's say this converter has a $200,000 WF printer that prints 1, 48X70 sheet every 10 minutes (because the job requires very high print quality, which slows down the print speed). Potentially- this printer can print 6 sheets per hour. Without ink and substrate costs, the hourly rate for the press is $152.00 (see table below). In this example, it will cost $152. (without ink/substrate) to produce 6, 48x70 (equivalent to 23.2 sq ft) sheets or $25.00 per sheet or $1.07 per square foot. Remember, this is the converter's cost-but the sell price is built from this rationale.

Example of How a Converter May Calculate Hourly Press Rate

A converter may determine how long the job will be "on press" then calculate the hourly rate, plus substrate cost, prepress, shipping charges and any other "value-added" services (which is a big variable that we will discuss later) and then adds profit to come up with a quote. Many converters consider the details used to create their hourly rate a secret, as it is an expression of their expertise and not just arithmetic. There is a science to quoting a sell price but there's also the "relationship" factor. The price may be adjusted just because of the relationship the converter has or is trying to build with the customer. The converter may give a lower quote to a client who buys a high-volume of print annually, or if the converter is trying to win a new job, or this WF job will allow the converter to gain other pieces of print (like post cards, mailings, flyers, etc).

Of course, in most cases, the print buyer does not know or care which hardware is used to print the job as long as it meets his/her standards and deadlines. A converter may need to move the printed location of a job to another press to meet delivery deadlines. Usually the hourly press rates, for those presses that produce comparable jobs, are deliberately constructed not to be significantly different, to allow for this "load balancing".

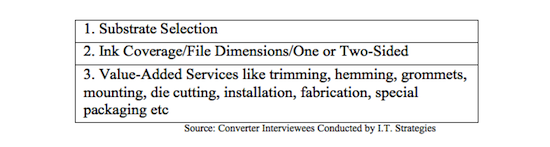

So-what is the current selling price of wide format printed output? Well-IT DEPENDS! A converter may use a "per square foot" calculation to determine selling price but the square foot rate is variable and determined by many factors. Interviewees said the top factor that influences the sell price of wide format print is substrate selection, followed by ink coverage/file dimensions/one or two-sided print, and then value-added services.

Major Factors that Influence the Selling Price of Wide Format Print

Converters also consider other factors when pricing wide format printed output. A list of secondary (value-add) factors that may increase the retail output price:

- Quick-turn/last minute request

- A converter may charge 25%-100% more for a rush order.

- Specialized Installation: travel, hardware, etc required

- This is sometimes considered a value-add service.

- 5%-100% depending on the complexity

- Printer is really busy

- 5%-25% more

- Ability to offer VDP or versioning

- 5%-25% more

- Prepress: prepping file and/or any edits, hard proof

- Proof can cost the customer $20-$100

- Prepress: often 15-30 min is built into hourly printer cost, additional prepress/edits can cost the customer $40-$100 for each hour.

- Shipping/Courier

Correspondingly, the following is list of secondary (value-add) factors that may decrease the retail output price:

- Loyalty to the customer

- Discount per job of 5%-100%

- Annual Print volume of a big customer or contract pricing

- Discount per job of 5%-100%

- Printer is idle/Business is slow

- Discount per job of 5%-15%

- Opportunity to capture additional jobs (higher volume/profit print)

- Discount per job of 5%-100%

- The Economy/Competition

- Quantity

Some converters may provide a slightly lower price per piece as order quantity increases to entice a larger order from the customer. However, many converters do not think quantity is a major factor in determining the sell price for digitally printed wide format because their print cost does not come down with volume. The converter may get a discount by purchasing a larger amount of a particular substrate, and this discount may be passed on to the customer for volume quantity savings.

Converters may offer discount based on total square foot purchased for larger jobs or over multiple contracts, and particularly if their equipment has higher throughput ability.