Remaining Nimble in an Ever-Changing Industry Landscape

The commercial printing industry is undergoing rapid transformation, especially in label and packaging printing, as sustainability, digitalization, and automation reshape the landscape. Today’s market dynamics present both challenges and opportunities, pushing companies to adopt new technologies and leaner workflows to remain competitive. SnapPress, with its innovative label printing solutions, is positioned perfectly to meet these evolving demands, helping commercial printers embrace small-run flexibility and advanced production techniques to attract emerging brands and maintain profitability. Leveraging the proven HP FI-1000 aqueous pigment ink print engine, the SnapPress LP-1 addresses critical needs voiced by the label community.

A Shifting Landscape: Sustainability and Innovation at the Forefront

One of the most significant shifts in the label and packaging industry is the ongoing push for sustainability. Companies are facing pressure from both legislative bodies and consumers to reduce environmental impact. This drive toward a circular economy has led to innovations in removable adhesives, material identification, and recovery systems. Sustainable printing materials—such as recycled and biodegradable substrates—are gaining traction. These developments enable better recyclability and the reuse of label materials, helping brands comply with evolving mandates for eco-friendly packaging.

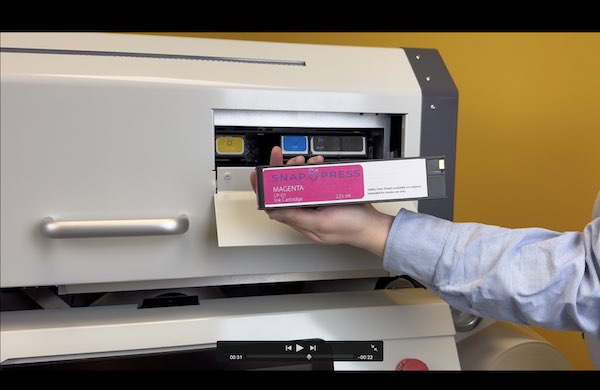

At the same time, the SnapPress LP-1 is uniquely suited for this eco-conscious shift. Designed for short-run opportunities, the LP-1 minimizes excess waste and energy consumption, aligning with sustainability goals and enabling brands to meet mandates for more environmentally responsible production. This emphasis on efficiency is complemented by SnapPress’ compatibility with high-capacity, aqueous pigment ink cartridges that reduce waste and environmental impact without sacrificing print quality.

Labor Challenges? Embrace Automation and Digitalization

Is the availability of skilled press operators impacting your ability to grow? Automation technologies for digital printing make it possible for printers to produce more precise, efficient outputs and help offset the rising costs of materials, inks, and coatings that challenge the industry today. In an environment where skilled machine operators are becoming harder to recruit, automated, user-friendly solutions are vital. Here, SnapPress proves invaluable. Our user interface is the simplest in the industry (“it runs like my iPad/tablet”), requiring minimal operator training. Almost any employee in your shop can run jobs on the LP-1 without being a highly skilled press operator. This reduces operational complexities and allows for high-quality, cost-effective production runs. See for yourself how simple it is to make labels with SnapPress in our virtual Demo Presentation with our CEO, Kevin Davis.

Additionally, digital printing advancements enable on-demand printing, a key aspect of customization and shorter turnaround times. As brands look to differentiate themselves through unique packaging, the ability to fulfill short-run, specialized label orders offers a competitive advantage. SnapPress LP-1, purpose-built for high-quality, small-run printing, supports label printers in shifting focus from large-volume orders to smaller, high-margin jobs, accommodating the custom needs of niche industries that seek personalized and immediate label solutions.

Long-Term Profitability Amid Market Challenges

While these new technologies provide immense growth potential, achieving long-term profitability in label printing remains a complex challenge. Rising costs for materials, labor, and business operations, coupled with uncertain legislation, put pressure on commercial printers to stay efficient without sacrificing quality. The consolidation of supply chains—both from manufacturers and brand owners—further squeezes printing businesses in the middle, driving a need for agile, cost-effective solutions.

SnapPress addresses these concerns by supporting label businesses in optimizing short-run jobs, minimizing waste, and reducing labor dependency through automation. By offering smaller, customized print runs, SnapPress enables commercial printers to maintain profitability even with low-volume orders, providing a model that makes smaller production both feasible and financially attractive. This is especially valuable as more brands embrace short-run labels, where custom, eco-friendly, and high-quality printing aligns with consumer preferences and regulatory expectations.

Challenges and Opportunities in Adopting New Technologies

Of course, transitioning to new technologies is not without its challenges. Financial investment, staff training, and changes to workflows are common barriers to adopting innovations in label printing. Smaller printing companies, in particular, face difficulties in financing new equipment and justifying the expense if demand for shorter runs is uncertain.

However, these same technologies present an opportunity to stand out in a crowded market. By incorporating solutions like SnapPress, label printers can offer high-quality, customized printing that caters to specific customer needs, creating a point of differentiation. Partnering with providers like SnapPress can also alleviate some of the burden by ensuring the technology is cost-effective, easy to implement, and equipped to handle the specific demands of custom label printing.

Actionable Insights for Industry Professionals

To remain competitive in this rapidly changing landscape, commercial printers must take a proactive approach to technology, sustainability, and strategic partnerships:

- Invest in Technology: Prioritize equipment tailored for short runs and niche orders, like the SnapPress LP-1, to keep upfront costs manageable and maximize operational flexibility.

- Sustainability as a Standard: Implement sustainable practices with energy-efficient, compact machines that support eco-friendly materials, reducing the environmental impact of smaller runs without large-scale infrastructure changes.

- Serve Niche Markets: Capture new revenue streams by offering smaller, customizable label runs, ideal for challenger brands in specialty industries. SnapPress’s compact label printers provide the agility and precision needed to meet the distinct demands of these emerging market segments.

- Collaborate with Technology Partners: Leveraging partnerships with technology providers like SnapPress can be essential to adapting to rapid changes and staying at the forefront of industry innovation.

Looking Ahead: Innovations Driving the Next Decade

The coming years will likely see continued emphasis on automation, digitalization, and sustainable practices in label printing. SnapPress is well-positioned to help commercial printers meet these trends head-on, enabling them to deliver innovative solutions to clients while maintaining operational flexibility. The label printing industry can thrive in a market that values agility, efficiency, and environmental responsibility through smart investments in technology and a focus on sustainable, short-run printing.

SnapPress stands as a trusted partner in this evolving journey, empowering label printers to navigate the challenges and leverage the opportunities of a rapidly changing industry landscape. With SnapPress, commercial printers can move confidently into a future defined by adaptability, efficiency, and environmental responsibility, helping brands connect with consumers in meaningful, memorable ways.

Get complimentary label samples or email your existing label files to [email protected] to discover the quality and functionality of the SnapPress LP-1 Inkjet Label Press.