(Image courtesy of Texintel)

By Marwa Zamaray, European Climate Pact Ambassador, European Commission

The Ecodesign for Sustainable Products Regulation (ESPR) is in force from July 18th 2024.

What’s ESPR?

It's the EU’s new rulebook to make products more durable, reusable, repairable, and recyclable. The rules proposed under ESPR will apply to all products placed on the EU market, whether produced inside or outside the EU. So, what does this mean for you?

At its core, ESPR demands transparency, responsibility, and a commitment to reducing environmental impact. This means redesigning products for longevity and recyclability, implementing robust traceability systems, and ensuring full transparency in your supply chains.

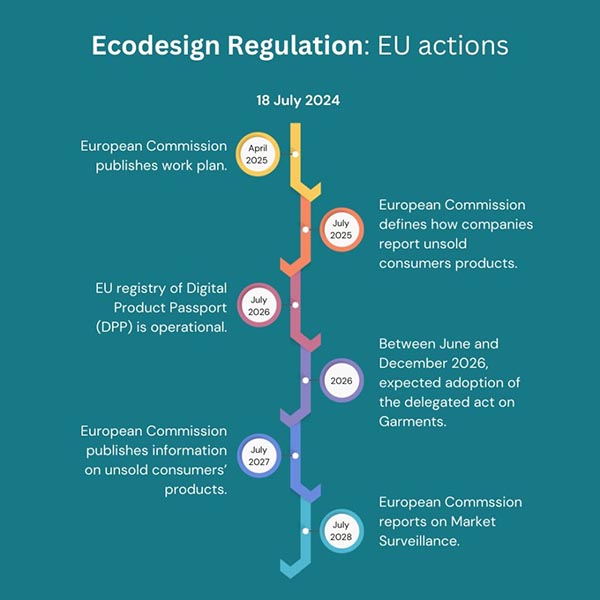

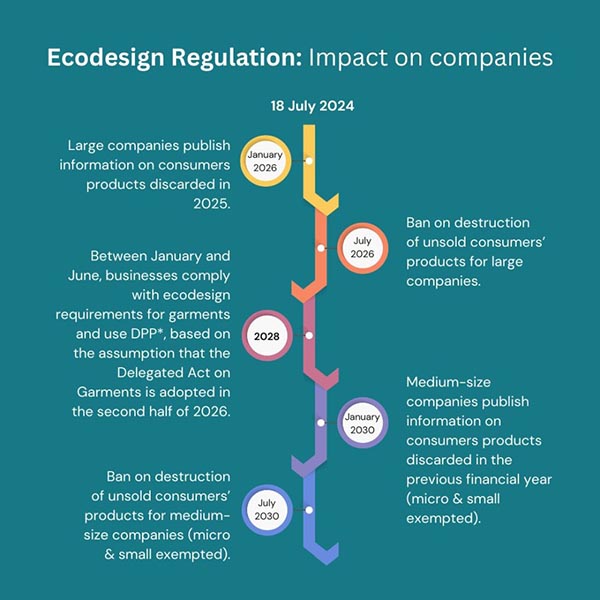

Mark your calendars for these crucial dates (Thank you, EURATEX - European Apparel and Textile Confederation for visualizing). Understanding the timeline of EU actions is important. These steps will shape the regulatory landscape and guide companies on compliance. Here’s what the EU has planned:

EU Actions Timeline

Key deadlines and requirements for large and medium-sized companies under the Ecodesign Regulation

As you work through those upcoming deadlines, don’t forget that just meeting these dates isn’t the whole picture. It’s not about scrambling to fix one issue at a time. Think of it this way:

“Taking a piecemeal approach to regulatory compliance is like trying to patch up a garment with mismatched fabrics—sure, it covers the holes, but it lacks the cohesion and quality of a well-planned design.”

Many companies tend to handle regulatory compliance one regulation at a time, especially as deadlines approach. However, this reactive strategy can have significant downsides, particularly for brands sourcing from high-risk regions and their suppliers in industries such as manufacturing, footwear, apparel, and consumer goods. It often leads to rushed, inefficient, and costly compliance measures, creating gaps and overlaps in adherence. Internal resources become strained due to continuous adaptation, pulling focus away from core activities.

This misalignment can cause strategic disconnects between regulatory requirements and business objectives, ultimately hindering the achievement of ESG goals. Therefore, it's crucial to adopt a strategic, holistic and long-term approach to regulations to stay ahead of your competitors, ensure business continuity and reduce legal compliance costs.

The Core Pillars of ESPR

1. Digital Product Passports (DPPs)

Think of DPPs as detailed resumes for each product, listing its origin, composition, and environmental impact. These passports provide consumers with the transparency they crave and regulators with the data they need to ensure compliance. And the stakes are high:

“By 2030, over 62.5 billion DPPs are expected to be issued globally, driving revenues of around $1.59 billion in software and IT designed to boost traceability and foster positive change in the fashion industry”. (Research from ABI Research)

2. Rules Against Destroying Unsold Products

ESPR bans the destruction of unsold goods, pushing brands to find sustainable alternatives like reuse and recycling.

3. Green Public Procurement (GPP)

This is about leading by example. EU authorities will now prioritize buying sustainable products, creating a ripple effect that boosts demand for eco-friendly goods.

Now, here’s the big question:

How can this ambitious regulation be successful? The answer lies in a high level of traceability.

Understanding Traceability

Traceability is the ability to track every stage of a product’s journey, from raw material to the final product. It’s about knowing the who, what, where, and how of each component that makes up your garment. For fashion brands, it means keeping a detailed record of every material, process, and supplier involved.

Why Is Traceability the Key for ESPR’s Success?

Because it’s all about data—accurate, comprehensive data collected throughout the supply chain. This data isn't just for show; it forms the backbone of the Digital Product Passport (DPP), a key component of the regulation.

But why is this level of transparency so crucial? Here are some reasons:

Consumer Trust

Did you know that 64% of shoppers are more likely to buy from brands they see as responsible? So, how can you meet these expectations? The answer is simple: Show them you are responsible!

Imagine having transparency over your entire supply chain and providing your customers with access to the full history of the product they purchased—where it came from, what it’s made of, and its entire journey. That’s traceability in action. And the tool? DPP. With a DPP, you’re instantly providing the transparency customers crave. Transparency equals trust—simple math.

Regulatory Compliance

The traceability mechanism ensures that brands are able to comply with the standards set by ESPR. It allows for easier verification and enforcement of these requirements, making sure that non-compliant products do not slip through the cracks.

“Brand reputation and the threat of heavy sanctions for failing to conduct proper supply chain due diligence, drives brands to maintain high standards of compliance.”

Achieve Sustainability Goals and Manage Supply Chains Effectively

The more robust and evidence-based the traceability, the easier it is to spot risks in the supply chain and areas for improvement. Too many brands only see their tier 1 and, at best, tier 2 suppliers, which is just the tip of the iceberg. For those unfamiliar, tier 1 refers to the garment manufacturers, and tier 2 refers to fabric suppliers (mills). Brands often miss out on tier 3 and tier 4 suppliers, such as yarn suppliers (spinners) and raw materials at the farm level, as well as subcontractors and suppliers' suppliers. The fashion supply chain is incredibly fragmented.

By peeling back these layers, or alternatively, by tracking from the origin of raw materials, you get the full picture—giving you the power to take informed decisions. This also helps you to pinpoint and tackle environmental and labor rights issues, counterfeiting, and reputational risks. In short, if you want to stay ahead of the curve, verifiable and data-driven transparency is your best friend.

Getting Started: Collecting the Right Data

The foundation of any good traceability system is data. You need to know everything about your products, from the country of origin for materials and processes to certifications and compliance data. Start by collecting all the necessary data points. This means gathering information even before a product enters production. Start now and be relentless. Prioritize high-risk areas first and expand your data collection systematically.

Collaborate with Your Suppliers

Yes, gathering data can be a hassle. But you don’t have to go at it alone. Engage your suppliers in this process. Build strong relationships with them and make sure they understand the importance of continuous data collection. Trust me, it’ll make your life a lot easier in the long run.

Some suppliers will resist change. Address this head-on. Invite them to strategy meetings, share the benefits of compliance and highlight potential risks of non-compliance. Make them feel like partners, not just vendors. Make it clear: their success is your success. At the same time, don’t shift the burden of compliance onto them.

Incentives for Compliance

To motivate suppliers, offer rewards for those who meet ESPR standards. Consider bonuses or preferred partner status as incentives. Make compliance advantageous for them. Also, provide training to your suppliers, explaining the specifics of ESPR and offering resources to aid their compliance.

Now, let’s dig into the details of what data you need to gather. To make sure you cover all the essential bases, here’s a checklist to guide you.

Standardizing Your Data

Now that you’ve got your data, it’s time to standardize it. This is crucial for ensuring that your data is compatible with various systems and platforms. Think of it like speaking a common language that everyone in your supply chain understands. Adopt global standards like GS1 for product identification and data sharing. This will help you manage decentralized information.

With that comes ensuring interoperability across different systems. Interoperability makes it easier to exchange and utilize information across the global supply chain. This is especially important as ESPR expands globally and you need to adapt to varying regional requirements without losing data quality or consistency.

Building Your Centralized Database

With your standardized data in hand, you need a robust centralized database to store and manage it all. This database should be secure (think encryption and access controls) and scalable to handle the growing amount of data you’ll be collecting. Make sure it’s user-friendly too. An intuitive dashboard that provides easy access to key metrics and data will make your life—and your team’s life—a whole lot easier.

Real-Time Monitoring and Reporting

Once your database is set up, it’s time to put it to work. Use analytics tools to monitor your supply chain activities in real-time. This will help you stay on top of things and quickly identify any issues that arise. And don’t forget about reporting. Generate compliance reports and consumer-facing product information to keep everyone in the loop.

The Final Touch

User Interface and Experience:

A good traceability system isn’t just about data—it’s also about how you interact with it. Make sure your system has a user-friendly interface that’s accessible via mobile devices. This will allow you to monitor your supply chain on the go. And don’t be afraid to customize the interface to meet your brand’s specific needs.

Continuous Improvement

Finally, remember that ESPR is not a one-time effort. It’s an ongoing commitment to sustainability. Regularly review and update your practices to stay compliant with evolving regulations. Engage with industry stakeholders and participate in consultations to stay informed about future requirements. Regularly audit your supply chain to ensure compliance at every level. Use third-party auditors if necessary. This will keep everyone on their toes and maintain high standards.

The brands that jump on this now, the ones that adapt and comply, will be the ones to thrive in this new eco-conscious landscape. The timeline is tight, and the requirements are rigorous, but the payoff is substantial.

All the best on your ESPR journey!

Need a hand with ESPR compliance? I’m keen to help global brands navigate complex legislations and optimize supply chains to meet ESG objectives. If you're feeling a bit overwhelmed by the new regulations or just want to chat about the best way forward, don’t hesitate to reach out.

Marwa, engineer in Fashion Technology and a sustainability consultant, champions ethical sourcing and compliance in the global fashion industry, focusing on impactful, innovative, and digital strategies. A dedicated sustainability consultant and advocate for ethical sourcing, with extensive expertise in legislative policy and compliance within the global fashion industry. She has collaborated with global entities to combat forced labor, animal abuse, and deforestation through innovative strategies. Focused on transforming supply chains to align with EU/US laws and global standards, Marwa combines her deep technical understanding with a history of delivering tangible results.

Her approach includes tailored strategies and a commitment to transparency, guiding multinational companies through complex legal landscapes. As a frequent speaker and contributor at significant platforms, Marwa intensifies her efforts through educational programs, social media engagement, and public speaking, aiming to educate, inspire, and engage communities in sustainable and ethical practices. Through her work, she champions innovative compliance strategies that resonate with market needs for environmental and social responsibility, driving tangible change in the fashion industry.