This article is sponsored by atomyx as part of WhatTheyThink’s Print Software Product Spotlight series. In preparing this article, the WhatTheyThink Print Software Section editors conducted original, in-depth research on atomyx’s cloud based platform. This Product Spotlight describes what the editors feel are the product’s strengths in the marketplace. atomyx reviewed the final article for accuracy but had no editorial control over the content.

(Watch David Zwang’s video interview with Tom Peire here.)

Imagine a cloud-based platform that could both streamline the print business and production processes, while also reducing the skills needed to do the plant-wide automation integration to support production from Mass Production to Mass Customization. That is the goal of the Atomyx platform.

Print continues to evolve to keep up with the changes in markets and technologies. While there are lots of changes, the bottom line outcome is that run lengths and production time requirements are trending downward, even to a quantity of one. To better support these new market realities, business and production processes need to change, and the cloud is a great facilitator, with the right tools.

In our increasingly connected world, we rarely see orders that are not delivered through the cloud by email, W2P, FTP solutions, EDI, etc. At the same time, a lot of business and production software tools moving to cloud based subscription services.

Moving business and production workflows to the cloud not only saves hardware and maintenance costs, more importantly it also decreases the total time needed to get the approved order to the output device and delivered to the customer. This savings is especially critical if you are providing order of one mass customization services.

Located in Gent Belgium, Atomyx founder and CEO Tom Peire, evolved out of Four Pees, a software distributor in the print industry helping bring a range of software companies’ products to market. Their core strengths included finding appropriate reseller channels and integrators to implement these software solutions. It also included direct educational outreach to the market. This outreach provided them the opportunity to get more directly involved with the print service providers. This led to the realization that, in many cases, the internal skills and bandwidth of PSPs and even some of the integrators really couldn’t support the expertise needed to develop plant wide automation. Even if the tools existed.

They found that with their own internal expertise, they could probably do a better job than many of the resellers and integrators, so they added integrations to their portfolio of services. After doing quite a few PSP integrations they began to realize that they were seeing many of the same inefficient processes in all the companies they worked with. These included many manual repetitive data input and process tasks, but importantly, they saw they could also use an easier way to build the integrations as well.

An increasing percentage of the PSPs are desperate to find ways to address the skilled labor shortage and reduce the time and cost of producing short runs, especially to a run of one. They also found that with the amount of disparate software and hardware that needed to be integrated in a plant, they probably needed to find a way to automate their integration process as well! That is the genesis of Atomyx.

Atomyx

Atomyx is built on the vision of Connected Automation to enable the profitable production of individualized print jobs at scale. Imagine a cloud-based platform that could both streamline the print business and production processes while also reducing the skills needed to do the plant wide automation integration. That is the goal of the Atomyx platform. According to Peire, “With Atomyx we want to enable printers to move from mass production to mass customization and make a ‘print of one’ profitable.”

Atomyx is built on the vision of Connected Automation to enable the profitable production of individualized print jobs at scale. Imagine a cloud-based platform that could both streamline the print business and production processes while also reducing the skills needed to do the plant wide automation integration. That is the goal of the Atomyx platform. According to Peire, “With Atomyx we want to enable printers to move from mass production to mass customization and make a ‘print of one’ profitable.”

By using Atomyx to integrate and connect different software products you can create a complete workflow to seamlessly take orders from customer through production and even send the final product back out to the customer.

The Atomyx platform consists of three products; manage, prepare, and layout, all of them residing and communicating in the cloud. They can also be integrated into Enfocus Switch flows with free apps. This functionality significantly adds value to both new and existing Switch flows.

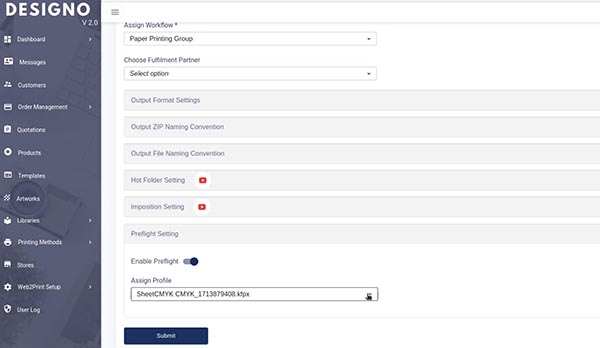

Atomyx Prepare has an API that can be integrated with external platforms to convert, check, optimize, and prepare files for onboarding. This is designed to work with on premise onboarding in conjunction with cloud based print procurement or MIS/ERP systems. At drupa, expect to see the self-onboarding functionality of Atomyx Prepare with OEM partners, DesignNbuy and Omikai, with others in the pipeline.

Atomyx Prepare has an API that can be integrated with external platforms to convert, check, optimize, and prepare files for onboarding. This is designed to work with on premise onboarding in conjunction with cloud based print procurement or MIS/ERP systems. At drupa, expect to see the self-onboarding functionality of Atomyx Prepare with OEM partners, DesignNbuy and Omikai, with others in the pipeline.

With this integration, Prepare processes and provides print ready files through the use of Callas pdfToolbox which is tightly integrated into the product. Since it can activate almost any of the pdfToolbox functionality, it can provide preflighting and fixes (if desired), color management and conversion, dieline awareness, etc. Of course it also supports industry standards like those from the Ghent Workgroup. Atomyx already has pilot customers in commercial print and self-publishing working with Prepare.

Prepare is a fully hosted and scalable SaaS solution which can seamlessly scale a print production processing capacity to manage seasonal and peak production without having to worry about software licenses and infrastructure.

Atomyx Manage connects “platforms and people.” It is designed to connect disparate software and hardware platforms, processes and people in the production process whether in the cloud, on-premise or spread across your customer and partner ecosystem.

Atomyx Manage connects “platforms and people.” It is designed to connect disparate software and hardware platforms, processes and people in the production process whether in the cloud, on-premise or spread across your customer and partner ecosystem.

The key elements in the Manage product are:

- Objects—Can be defined by any objects and its properties

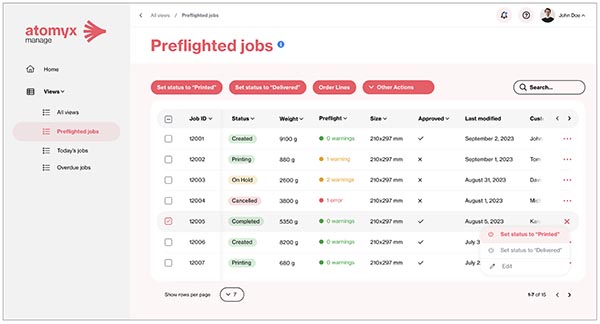

- Views—Configurable to specific workflow steps or insights

- Triggers—Start an automated series of actions

- Objects—Can be defined by any objects and its properties

- Views—Configurable to specific workflow steps or insights

- Actions—Apply individual or bulk changes on objects

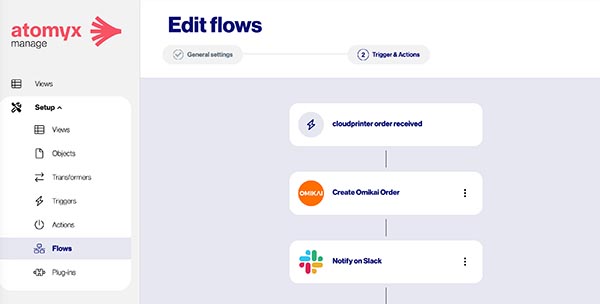

- Flows—A sequence of triggers and actions

- Plugins—Provides packaged add-on functionality

The “plug-in” architecture is an API to enable inter application communication. The functionality can coordinate the movement of business or production content through the end to end plant manufacturing process. Current plug-in categories are designed for file sharing, order platforms, web2print, MIS/ERP, CRM, prepress systems, local automation (Enfocus Switch, HP SiteFlow, etc.), RIPs, business platforms, payment platforms, accounting software and business analytics, as well as other types of API add on functionality. At drupa, expect to see Atomyx Manage integrations with Omikai MIS system, Slack, and Enfocus Switch.

Manage has a configurable dashboard to view and automatically or manually act on a process or status. This can include process times and can send that information back up to another connected system for analysis.

Atomyx Layout is designed to optimize paper and media usage by creating the most optimal print layout. You can also use it to quickly estimate jobs with different sheet sizes and presses, while using one imposition tool for all of your print jobs. It is designed to be easy to integrate with any MIS or production automation product. It will support pressready layouts for bound, flat and step-and-repeat work. It will also support automated ganging and true shape nesting all using a template-free imposition solution. The goal is to provide cost-efficient planning and evaluating make-ready, plates, press time, and materials.

Atomyx Layout is designed to optimize paper and media usage by creating the most optimal print layout. You can also use it to quickly estimate jobs with different sheet sizes and presses, while using one imposition tool for all of your print jobs. It is designed to be easy to integrate with any MIS or production automation product. It will support pressready layouts for bound, flat and step-and-repeat work. It will also support automated ganging and true shape nesting all using a template-free imposition solution. The goal is to provide cost-efficient planning and evaluating make-ready, plates, press time, and materials.

Pricing Structures

Since the Atomyx platform products are cloud based solutions, the current pricing model is based on usage. Each of the products has a different pricing model to provide competitive and scaled pricing for each.

The Manage product annual pricing is based on users, views, plug-ins and storage. Manage also has pricing for external users. These could be customers or perhaps even other applications.

The Prepare product pricing is based on “threads” and “credits.” Threads have a fixed charge to provide a dedicated processing channel, and depending on your usage you could need multiple threads. These are charged at a scaled rate dependent on volume. Credits can be used in conjunction with threads to manage your variable workloads. These are also charged at a scaled rate dependent on volume.

Layout is still in very early development and as such, a pricing model has yet to be determined.

Summary

This is a unique and ambitious platform of products and services. It could undoubtedly change the way many PSPs do business, and support the new realities of a connected world once it is fully implemented.

Today, the Prepare product is actually being used in production at a few PSPs while it is being further developed. The Manage product is in development and while not being used in production yet, is targeted at early user testing by the end of the year. Layout is currently in very early development.

Discussion

Only verified members can comment.