Since the theme of this issue of WhatTheyThink magazine is about finishing and embellishment, we thought it would be cool to embellish the cover. So, we asked our friends at Konica Minolta, sponsors of this issue, if they’d like to help us create it.

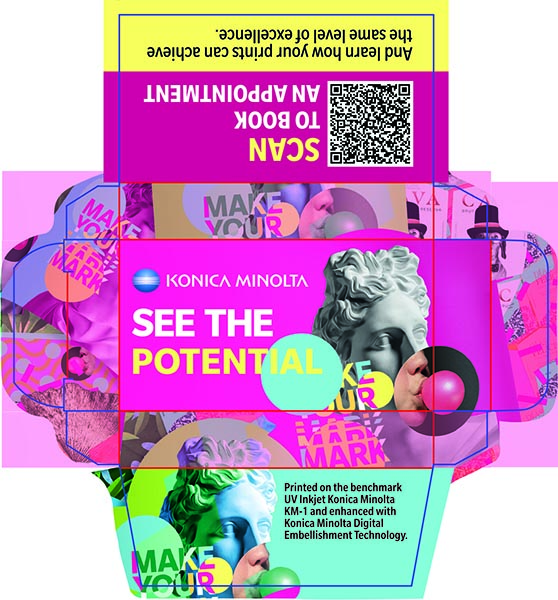

Sure, they said, but we have another idea. Instead of embellishing the cover, what if we attached an embellished piece to it? Something the reader could pull off and interact with? A design that demonstrates new techniques using texture, color, and form to inspire and show “the art of what’s possible.”

That was the beginning of the plan to create this fun and unusual cover, incorporating not just digital embellishments but plenty of other finishing treatments. Here’s how it was done.

The idea for the format of this piece came from a business card design developed by Konica Minolta client, Elite Print Finishing (EPF) out of Burlington, N.C. After installing an MGI JETvarnish 3D Evo, EPF created promotional business cards that could be folded into tiny, embellished boxes. For this project, the question was, could an embellished, folded card box be tipped onto the cover of a magazine?

Enter Royle Printing, the folks that print this magazine. After some testing with sample pieces, the Royle team found that the card boxes could be tipped onto the front cover. With that green light, the project started in earnest.

Once the Konica Minolta design team shared the artwork for the card box piece, the WhatTheyThink design team incorporated it into the front cover design. The artwork had to be placed at a reduced scale from the full-sized piece, to minimize the possibility of the background art peeking out from behind the box piece once it was tipped onto the cover.

Worth-Higgins and Associates in Richmond, VA printed the four-color box designs onto 10pt C1S sheets. The finishing and embellishment magic happened at EPF, where the pieces were laminated on a D&K high-speed laminator, 3D coated and silver foil stamped on a JETvarnish 3D Evo, then die cut and glued on Bobst finishing equipment.

The folded but flattened pieces went to Royle Printing where they were tipped onto the front cover with a dot whack of glue and then the magazine was placed in a polybag to ensure the card boxes remained intact during mailing.

We hope this cover ignites a spark for some great finishing and embellishment ideas of your own!

Discussion

Only verified members can comment.