It’s no secret, and not new, that many print service providers are diversifying their business to stay competitive and grow. Commercial printers are adding large-format offerings, and large-format businesses are moving into specialty print applications. Print operators are now managing a range of print jobs across multiple printers, presses, and finishing equipment from different manufacturers. One key to success is unifying print rooms with just one centralized job management workflow that transcends print technologies, printer brands, and models — consolidating all print production processes.

We sat down with John Henze, VP of Sales and Marketing at Fiery, LLC, the leading independent provider of digital front ends (DFEs), to discuss how PSPs can unite their digital print rooms as they expand into new markets with new equipment.

WhatTheyThink: As PSPs look to expand and grow their businesses, where are the biggest opportunities?

John Henze: By far, the most significant growth opportunities for PSPs lie in diversifying into print products that complement what they already produce or fall into strong-growth areas.

John Henze: By far, the most significant growth opportunities for PSPs lie in diversifying into print products that complement what they already produce or fall into strong-growth areas.

What I mean by “complement” is that if a PSP serves the healthcare sector by producing leaflets and flyers, chances are the same customer will need posters and signage to support the campaign or initiative. Most customers would prefer to deal with just one supplier, especially if color consistency is a priority for them. This is why many commercial printers have moved into large format print, it’s a logical next step.

Another growth area that remains very strong is personalized printed products and specialty production. That’s anything from printing directly onto garments to engraving onto merchandise, or printing labels, folding cartons and much more.

WTT: What should PSPs consider before entering new print markets using new technologies?

JH: Typically, PSPs do a great job assessing the market they are entering and the growth potential it will bring. Plus, they do a fantastic job researching the capabilities of a new printer to ensure that it can do what they need. These are essential business steps.

However, many print owners overlook how they will ‘drive’ their new technology investments and integrate them into existing workflows. No doubt the new printer, imaging, or finishing technology comes with software, but PSPs should go further and ask how the software or server maximizes their new investment. Will it integrate with their existing software investments and workflows? What is the learning curve of the software?

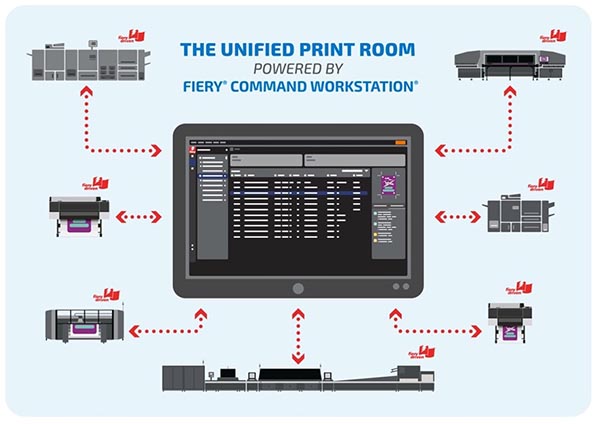

With so many different print technologies and manufacturers, another challenge PSPs face is figuring out how new print investments fit with their existing equipment to manage their print room efficiently. How can printers bring uniformity to their print room, making it easier for staff to manage print jobs across all digital print investments – especially as they expand into new technologies? At Fiery, we call this developing a unified print room.

These are important questions print owners need to think about in advance if they want to hit the ground running with new investments and start profiting right away.

WTT: How can a PSP unify their print room?

JH: The idea of a unified print room is about standardizing what manages your digital print job production—no matter what the print technology or manufacturer. This makes the introduction of new printers and presses easier.

If the workflow is known, then employee training is partly done. This is particularly important while we are still in the climate of limited skilled resources in the print industry. For example, if the software driving new printers is familiar (which Fiery technology tends to be), staff can focus on what the new technology can produce. Basically, the new printer can just slot straight in and do what it was purchased to do, which is expand the offerings of the PSP.

To achieve a unified print room, all print production is taken care of by the same RIP and workflow solution. Having one centralized interface to manage all print production makes it easier to onboard new staff, train employees on new press investments, and produce high-quality jobs almost immediately for maximum return on investment.

WTT: How is Fiery leading the way in unifying the print room? And what makes Fiery’s approach unique in the market?

JH: Fiery DFEs are the only RIP and workflow solutions that drive cutsheet toner presses, highspeed inkjet printers, plus wide to superwide devices. This makes us uniquely positioned to help unify the print room. No other software vendor has this same reach.

For example, alternative DFEs are provided by printer manufacturers, but they only work with their own equipment. The software is provided because it’s needed to make the equipment run. However, when PSPs need to expand into new areas or use different manufacturers’ print technology, this can lead to many different DFEs with different workflows in a single print room, or worse, PSPs being trapped into one-manufacturer solutions. As an independent provider that transcends manufacturers, Fiery offers unique advantages and enables PSPs to invest and grow their businesses while keeping familiar workflows.

Of course, print engines differ across technologies and print manufacturers. Each Fiery server leverages our core RIP innovation and is optimized for a specific print engine/manufacturer catering to different screening requirements, equipment innovation, ways to transfer print data, and more. What ties all our Fiery DFEs together and makes them uniform is Fiery Command WorkStation job management software.

Fiery Command WorkStation is the “window in and conductor of” production. It’s the central interface where you manage jobs for print, apply color management, and schedule jobs for the most effective use of your Fiery driven resources. It also gives you a bird’s eye view of all your production—from one location.

WTT: Are there other Fiery tools that work across different press types that can help streamline print room operations?

JH: There are. We know the end customer expects consistent color across printed products – regardless of the print technology used. It all has to match. Fiery Color Profiler Suite is the color management solution for all Fiery Driven™ printers. It’s basically the tool that provides integrated color management and control for anything that’s driven by a Fiery DFE.

There are big differences in printer gamuts across print technologies, and matching results needs good color management. Having Fiery Color Profiler Suite across all Fiery Driven technology doesn’t alter the laws of color science — it can’t make a printer’s gamut bigger. Instead, it provides one color toolset that works across Fiery driven devices to establish a unifying process for profile creation, inspection, editing, color quality assurance, and output enhancement. This makes everyday color management tasks easier and more routine, even for less experienced users, resulting in better color.

WTT: Lastly, what advice do you have for PSPs as they look to diversify to grow their businesses?

JH: That’s an easy one, “go for it”. If you think about it, diversifying is what Fiery continually does in terms of acquisitions, investments, and innovation to keep our business strong and at the forefront of where we sit.

Secondly, don’t underestimate the impact of how new technology fits into what you already do and how you do it. If you need to adapt your workflows to accommodate a new printer, incur extra training overheads, and develop new support agreements and procedures, this can take away some of the benefits of diversifying.

As PSPs look to expand, do your market analysis, printer research, and workflow fit. And remember, Fiery Command WorkStation can help unify job management and production workflows across all your Fiery driven servers to gain operational efficiencies and increase productivity. Most importantly, it can play a big part in the success of your business growth.

For PSPs who want to learn more about workflow fit or unifying their print rooms, we offer free resources available at Fiery Learning and Fiery Communities, and Fiery users can download the latest Fiery Command WorkStation today.

Discussion

Only verified members can comment.