We spoke with Patrick Keller, Division President, Baldwin Technology Co., about the history of the company, its broad set of solutions for a vast array of industries, including many aspects of print, and how being part of the new BW Converting Group benefits the company and its customers.

WhatTheyThink: Let’s start with a little bit of your personal background. How did you come to Baldwin?

Patrick Keller: I’ve been with Baldwin now for about three years. I came from a completely different industry, through a company called Eaton, a global electrical manufacturing conglomerate, and was heavily involved in the oil and gas portion of the business. I’m a mechanical engineer by education, but quickly went into different aspects of the business, focusing on our international expansion. I spent a lot of time across Europe, the Middle East and Asia, and ultimately had the opportunity to come to Baldwin to work on some of the initial efforts to integrate the business in a much more global way.

Patrick Keller: I’ve been with Baldwin now for about three years. I came from a completely different industry, through a company called Eaton, a global electrical manufacturing conglomerate, and was heavily involved in the oil and gas portion of the business. I’m a mechanical engineer by education, but quickly went into different aspects of the business, focusing on our international expansion. I spent a lot of time across Europe, the Middle East and Asia, and ultimately had the opportunity to come to Baldwin to work on some of the initial efforts to integrate the business in a much more global way.

WTT: Baldwin is more than 100 years old and is active in just about all aspects of print manufacturing, including packaging and labels and textiles. Talk a little bit about the company, its history, and where you stand now.

PK: Baldwin is a very well-rounded, mature business that started with our legacy surface cleaning technology. Part of what’s interesting about Baldwin, and why it’s tailored itself so closely to Barry-Wehmiller—which is our parent company—is that if you look at Baldwin over the past hundred years, we’re more than 15 different acquisitions, and the culmination of different businesses that bring unique solutions that deliver value to various print and industrial markets. We then are able to bring all those solutions together and be one of the most robust solution providers. And when we say a “solution provider,” we focus on enhancement equipment. We don’t manufacture the presses themselves—our sister divisions do—but we focus our efforts on enhancing any type of industrial equipment, whether it be presses or other equipment in the industrial space, such as the textile industry. Several examples of industries we service with various solutions include flexible packaging, commercial print, corrugated, as well as textile, EV battery, wood finishing and metal. No matter the industry, we focus on enhancing our customers’ processes to allow people to run more efficiently and reduce downtime. Our whole philosophy is, we change for the better. And that ties into the Barry-Wehmiller philosophy of creating a better world.

WTT: What are some of those “enhancement products” and some recent innovations?

PK: We really focus on three different value-driving categories. The first one being “speed and reduced downtime.”

One product that delivers on this value is our LED-UV portfolio. The advantages of LED-UV over conventional mercury and arc lamps for ink curing are too many to name. Our LED portfolio is tailored to meet specific needs of conventional offset, flexographic and digital press manufacturers and printers.

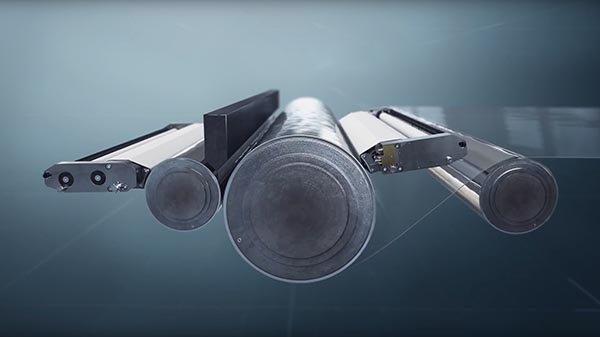

FilmCylinderCleaner

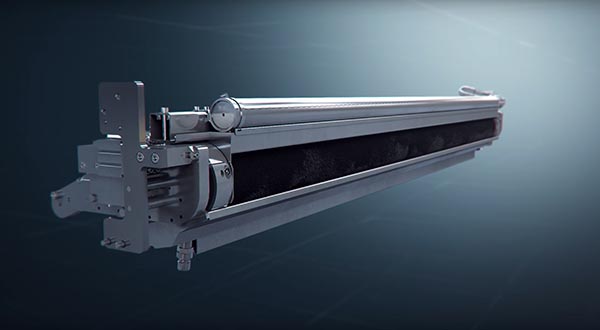

Speaking of the flexographic market, for the corrugated industry, we have a product called the FlexoCleanerBrush that takes the manual effort of cleaning plates and cylinders out of the equation when doing job changeovers and allows press operators to clean in-line during jobs. And it’s right in line with a product that does the same thing for film extrusion called FilmCylinderCleaner, that puts a roll of wet cloth onto the machine and automatically cleans the cylinder while in use. In addition to providing equipment, we provide the solvent-treated rolls for continuous use, which we call PREPAC. So our customers can rely on us to be a full solution provider with equipment, consumables, and service.

FlexoCleanerBrush

WTT: What is the second area you focus on?

PK: The second area we focus on is “efficiency.” A shortage of skilled labor is becoming an increasing issue across the industry. Print compared to a lot of other industries is really seeing the signs of an aging workforce. So how do we combat that with solutions and automation? Our goal is to automate our customers’ processes which provides them the most options on how to utilize their workforce. One of the product solutions we’ve focused on is our 100% inspection for print, spotting quality defects, verifying graphics and data (i.e barcodes) and being able to automatically ensure that the product going out the door meets expectations. Again, that reduces waste but also reduces any type of returns or reprints.

PREPAC

Another area that we’re involved in is color—and inks in general. We have a solution called Remote Ink Control that can automate a full closed-loop cycle where we analyze the color compared to what they’re trying to achieve and make automatic adjustments. For many years, a press operator would be required to manually adjust color by twisting each knob to get a color match by eyesight. Now, we have software solutions that tie back to automated control adjustments. So we’re reducing waste, but allowing efficiency to be maintained in the process.

WTT: And that’s the third area you’re involved in—reducing waste.

PK: Correct! “Reducing waste” plays right into the buzzword of sustainability. We have register control products that verify print and color are in alignment as it goes from station to station. We also have precision spray equipment that drastically reduce the amount of required chemicals to be utilized in the production process.

WTT: Baldwin is now part of BW Converting Solutions (BWCS), which launched at PRINTING United last fall. What is BWCS, how does Baldwin fit in, and what does it mean for Baldwin customers?

PK: I should start with our parent company Barry-Wehmiller, which is run by Bob Chapman. What he focuses on is both performing with excellence and caring for people—you can’t care for people if you don’t perform as a business, and you can’t perform as a business if you don’t care for the people in it. Barry-Wehmiller is made up of four different platforms currently, one of them being BW Converting Solutions, combining well-established businesses such as Winkler+Dünnebier, Hudson Sharp, PCMC, Northern Engraving and STAX. There is a large overlap in the customer bases we serve. So in an effort to get closer to our customer base and to be able to leverage our global footprint capacity with the people that we have, that was an opportunity for the division to come together. In early 2023, the decision was made to bring Baldwin into BWCS to further strengthen the converting platform. Not only do we add value to our customers, we strengthen BWCS’s presence within the markets it serves.

WTT: So other companies under the Barry-Wehmiller umbrella manufacture presses and Baldwin provides auxiliary solutions.

PK: Baldwin’s goal is to provide innovative, efficient, sustainable solutions to customers throughout the world. This would include meeting BW companies’ needs and their customers as well. We remain Baldwin but are working to position our brand to better service our customer base.

WTT: When you’re talking about going after new customers, where are you looking? Where do you see the growth in the industry?

PK: We grew up in the offset space and that has been an area, especially through COVID, that has really struggled. But it is a very large market. People say, “Oh, print is a dying industry.” It’s not, by any means. Is it seeing double-digit growth? No. But the offset space is a very robust industry that is seeing flat growth, but it’s where we cut our teeth. It’s a huge portion of the market that we serve. Where we see a lot of the potential is what we call “growth print,” such as flexographic and digital. A lot of our focus is around those industries and we’re also going after adjacent markets where you see different applications and printing methods being adopted. We have some great relationships with various OEMs in the curing space. In terms of UV curing, EV batteries have a significant requirement for UV curing. Then we talk about film extrusion, so anything involving film and sustainable plastics, those are the types of things that are really seeing good signs of growth. Within that, there’s a lot of change. Our philosophy is “change for a better world.” Change is inevitable, but our product solutions allow our customers to change to meet their future demands.

WTT: What’s your outlook for 2024? What do you think are some of the challenges and what do you think some of the opportunities for the next year are going to be?

PK: It’s a mixed bag. There’s a lot of uncertainty in the market. I’d say there’s also a lot of optimism—I think the market is more stable than people expect. But inevitably—and you see it in different regions, such as in Europe—there’s a lot of angst around situations which influence Europe, both in terms of technology and money that’s fed into the economy. We see a lot of customers are holding back on large capital expenditures, which is not necessarily a bad thing for us as they may be holding back on larger investments, but they’re moving forward with a lot of their maintenance, repair and operational budgets. It’s all about increasing the efficiency of their existing machines, and since we sell auxiliary equipment, we see that demand. Like a tale of two cities— we’re seeing some large opportunities where we’re talking about upgrading every machine in a customer’s facility and it’s a multimillion-dollar package, but they’re also saying, “This machine is about to die, we need to extend the life of it.” That’s where we’re really trying to leverage the potential of upgrades on our machines. Even with our existing customers where we’ve had solutions out there for 15 plus years, we’re doing a lot of service visits and control upgrades to ensure the system stays running. We definitely expect another good year, a lot of growth, and as part of BWCS, we’re getting a lot more potential to be in front of customers, especially from an aftermarket and service aspect. One thing we really pride ourselves on is the relationship aspect of our business. When you’re in front of customers, you’re asking them questions; that’s when opportunities arise and relationships are strengthened.

WTT: Is there anything else you’d like to add that we haven’t touched on?

PK: It’s always a journey. And even though we’re now part of an over-three-and-a-half billion dollar company, you still get the entrepreneurial feel of a small business wanting to grow. We’re in a good spot, but we have to continue to challenge ourselves to innovate for our customers because change is inevitable.