Recent supply chain issues and geopolitical developments, along with the increasing focus on sustainability, have created challenges for printers seeking a reliable supply of plates from suppliers focused on minimizing their carbon footprint. In light of these challenges, KODAK SONORA XTRA Process Free Plates, manufactured at Kodak’s Columbus, Georgia, facility are a smart choice for any printer.

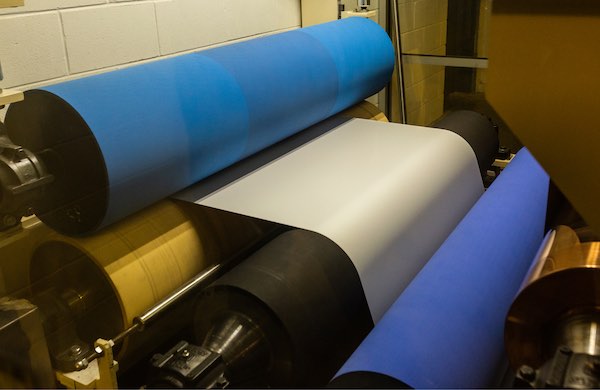

Kodak has a long history of manufacturing high-quality and technologically advanced offset printing plates to exacting standards. Kodak’s state-of-the-art plate manufacturing plant in Columbus, which has been making offset plates since 1991, underscores the company’s commitment to greener, local production of consumables. Thanks to the production facility in Columbus, Kodak is the only remaining manufacturer of aluminum-based offset printing plates in the U.S. and can reliably supply printers in the United States and Canada.

The location on the North American continent and the well-established supply chain and logistics infrastructure in the country ensure that KODAK printing plates made in the USA can be shipped quickly and efficiently in all required formats and quantities so that customers across North America are supplied on time.

In contrast, the purchase of plates shipped from certain Asian countries may be impacted by extended shipping times, potential delays at customs and other uncertainties, which may thwart timely delivery of the indispensable consumables to printers.

Local Manufacturing + Process-Free = Compelling Sustainability Benefits

The procurement of plates from domestic manufacturing reduces the carbon footprint due to significantly shorter and more efficient transport routes. In addition, in the case of SONORA XTRA Process Free Plates, the product itself is considerably more sustainable and has a more favorable ecological footprint compared to traditional wet processed plates.

The switch from processed plates to SONORA XTRA Plates eliminates electricity, water, developer, replenisher and gumming solution, and clean-out finisher required for traditional plate processing. Since there isn’t any chemistry used, and no plate processor in need of cleaning and maintenance, there are no waste chemicals or contaminated residual liquids to be disposed of. Furthermore, printers benefit from more consistent and stable plates that enable more reliable press make-readies and no downtime and paper waste due to plate processing defects. Logically, this also means that SONORA Plate users can streamline their platemaking operations enormously, get to press much faster, and reduce job turnaround times.

All of this can make a huge difference in terms of carbon footprint. For example, Kodak estimates a large printing operation can cut its CO2 footprint by 483,203 kg per year by transitioning from traditional processed plates sourced from China to SONORA XTRA Process Free Plates manufactured domestically in Columbus—a 37% CO2 saving! This reduction in CO2 emissions from just one print shop is equivalent to not burning 541,262 pounds of coal per year.

Plates from the Local Market for the Local Market

Zhijun Zheng, Site Director at Kodak’s Columbus Plate Plant, answers a few questions regarding the production of SONORA XTRA Plates at Kodak's plant in Columbus and their delivery to customers.

Zhijun Zheng, Site Director at Kodak’s Columbus Plate Plant, answers a few questions regarding the production of SONORA XTRA Plates at Kodak's plant in Columbus and their delivery to customers.

Why is it important for Kodak to continue manufacturing plates in North America?

Kodak’s name and logo are American icons. Kodak’s success in the United States highlights the idea that hard work and ingenuity can fuel a successful recreation of a company’s brand. Our lithographic plates are just one example of Kodak’s new, successful product lines. By maintaining local plate production in Columbus, we can ensure a reliable supply of high-quality KODAK Plates to printers domestically and in other countries in the Americas. It also allows us to keep the specific expertise and technical skills for plate manufacturing in the country and secure close to 200 jobs in the local Columbus community.

From a sustainability perspective, it should be obvious that aluminum-based plates trucked throughout the United States from a local manufacturing source will have a lesser environmental impact than plates that are either shipped or flown into the country, only to then also be trucked to their final destinations. For the Columbus site, Kodak’s, as well as the State of Georgia’s focus on sustainability, are very much in alignment with Georgia being ranked as number six in the United States in the Forbes Sustainability Index.

What are the benefits to U.S. printers of using Kodak plates made domestically?

With many of Kodak’s customers keeping tight control of their inventory and attempting to keep inventory low, a domestic source is the logical choice to quickly replenish those inventories in the event of inventory disruptions or sudden increases in demand. Kodak’s domestic customer support and field service engineers provide quick and effective support for printers throughout the United States. With support scattered across the country, technical assistance is only a quick phone call away with little impact due to time zones or other barriers to a quick response.

What processes have been implemented at the Columbus plant to ensure the most eco-friendly/sustainable and high-quality plate production possible?

KODAK Plates produced in Columbus fall under the site’s ISO 14001 program, ensuring consistency in our commitment to environmental, health and safety standards. The site continually strives to reduce its environmental impact. Virtually all aluminum consumed at the manufacturing plant leaves in the form of either offset plates or is sent to a local recycler. Not only does this make economic sense, it also eliminates the need for any valuable aluminum disposal in local landfills. Chemicals used in plate manufacturing are recycled back into the process not only to manage costs but to also reduce waste disposal volumes and environmental impact. Air emissions are minimized at the site due to oxidizers which prevent the escape of volatile organic compounds (VOCs) into the environment. Kodak’s commitment to the environment as well as to our customers in the printing industry goes hand in hand by considering waste reduction and recycling wherever possible.

Why are SONORA XTRA Process Free Plates manufactured at the Columbus plant a better solution for printers in the Americas than any other “process free” plates on the market?

Kodak is the inventor of the true “process free” thermal photopolymer printing plate. In 2005, Kodak launched the first commercially successful process free plate, the KODAK THERMAL DIRECT Non Process Plate. In 2012, Kodak introduced the first SONORA Plates which, due to expanded capabilities, made process free a reality for a larger population of printers. Since then, SONORA Process Free Plates have been through many generations of improvement to meet a wide range of customer requirements. The most critical feature of SONORA Plates is to enable printers to run their businesses more sustainably and eco-friendly without having to compromise on image quality, productivity and run length stability. SONORA XTRA Process Free Plates manufactured at our Columbus site combine advantageous sustainability properties with multiple quality and application benefits such as fast imaging, high resolution, excellent reproducibility as well as improved handling robustness that no other plates on the market can offer.

An Obvious Choice

All things considered, one thing becomes clear: By opting for KODAK SONORA XTRA Plates produced in Columbus, printers are making a very wise choice. They use the most technologically advanced process free plate, manufactured to the highest environmental standards. In addition, they can be assured of reliable supply and receive a high-quality plate product with unmatched sustainability benefits in daily use.