By Dieter Finna

Several new developments from Xeikon set fresh highlights in digital printing. On the one hand, the speed-trimmed LX3000 digital press offers higher productivity in label printing, then there’s TITON toner technology, which opens up new areas of application in flexible packaging as well as in print finishing, and finally, a fundamental improvement in the sustainability of the dry toner process itself.

Dry toner technology has had a decisive influence on the success of digital printing processes for more than two decades. Dry toner stands for process stability in printing as well as for high levels of food safety. Both of these properties have contributed significantly to the continued organic growth of the process. What was missing until now was the developmental push towards higher printing speeds and higher productivity. Xeikon is now fulfilling this. This development is driven by intensive research work in industry and the availability of new materials. However, legal requirements and changing market conditions are also forcing the development of the process.

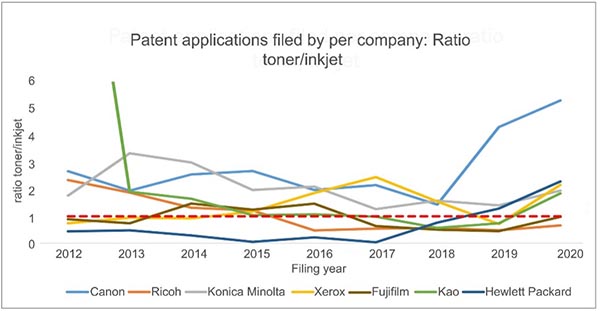

Patent Situation

The dry toner process has a consistently high potential for innovation, which is also reflected in the patent application situation. The chart below shows the number of patent applications of international companies which are active in both inkjet and toner processes. A number above 1 in the graph means that a company is filing more toner patents than inkjet patents. The timeline shows that inkjet filings of these companies outweighed patent filings until around 2017/2018. Since 2018/2019, the ratio of toner patents to inkjet patents has increased significantly. This shows the increasing relevance that toner patents have for these companies today. While the development of inkjet processes is about to reach physical limits in terms of speed, toner processes are only now experiencing the anticipated boost in terms of a combination of productivity increase, portfolio expansion, sustainability, and food safety.

Since 2018/2019, the ratio of filed toner patents to inkjet patents from international companies active in both, toner and inkjet has increased significantly. (Source: Xeikon)

Xeikon LX3000

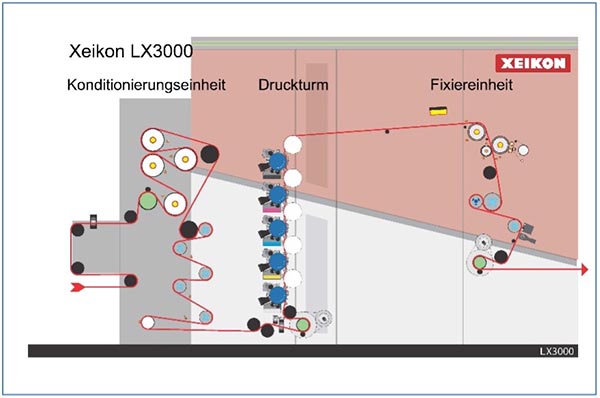

With the LX3000 digital press trimmed for higher speed, Xeikon is taking an important step towards increasing productivity in dry toner printing. The machine is designed as a high-end solution for the self-adhesive label market. It prints at a maximum speed of 42 m/min (137 ft/min), 40% faster than comparable machines, and a 1200 dpi print resolution meets the high demands in the field of high-quality labels. The LX3000 digital press has five printing units; CMYK + White and is designed for a web width of 330 mm (13"), with a print width of 322 mm (12.67").

Construction details of the high-speed dry toner press LX3000 with conditioning unit, print tower and fuser unit. (Source: Xeikon)

Packaging Printing with TITON Dry Toner Technology

In addition to increasing productivity, Xeikon also succeeded in expanding the process to new, food-safe applications. This was implemented through a further development in the toner area, which is on the market under the name TITON Toner.

TITON toner was developed for printing on fibre-based substrates such as barrier papers in flexible packaging. For this purpose, the toner is equipped with the necessary seal resistance when sealing the printed packages in the filling machines, which conventional dry toner types do not have. The heat seal resistance is achieved through cross-linkable polymers in the toner's formulation, with the cross-linking taking place in the press through an additional LED curing step.

TITON toner is seal-resistant, in contrast to conventional dry toner, which have insufficient seal resistance when used in flexible packaging, as can be seen in this photo. (Source: pack.consult)

This cross-linking step in the press immediately after fusing, makes TITON toner heat-seal resistant and resistant to mechanical and thermal stress, giving the properties required for use in flexible packaging. The printed toner layer is completely odourless and differs in this respect from conventional ink systems in packaging printing, which can contain residues of solvents in the dried ink film.

The Xeikon TX500 digital press has an LED unit on board for crosslinking the TITON toner, which happens after the powder image has been transferred to the paper-based substrate and the toner components have been fused to the printing material at a temperature of approx. 100°C. (Source: pack.consult)

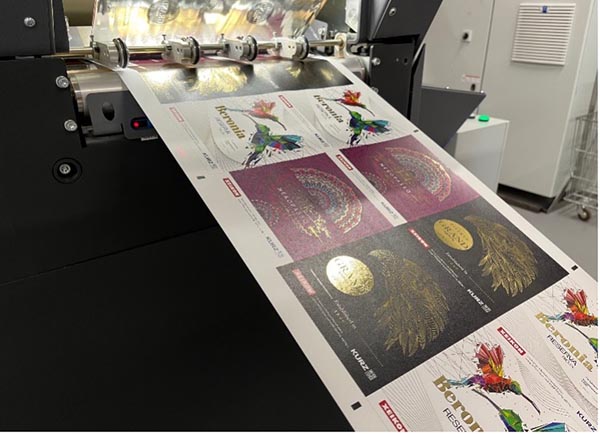

Print Finishing

Another area of application that TITON toner opens up due to its temperature resistance is in print finishing for labels. For printers who already produce digitally printed labels using the toner process and are looking for extended design options for their customers, TITON toner offers the possibility of digitally finishing labels and packaging inline, in one production run. This is done using a finishing module from Kurz, which is installed inline behind a Xeikon TX500 digital press.

In the prototype of a Kurz finishing module shown here, the finishing foil is applied to the substrate. (Source: Xeikon)

The printing tower of the TX500 digital press has five printing units, four of which are equipped with the process colors of the TITON toner. In the fifth printing unit, an imagewise dry toner layer is applied with the well-known QB-CH toner. When the web then enters the Kurz finishing unit, the image elements printed with TITON toner are heat-stabilised, while the toner layer printed with QB-CH toner is melted by a heated roller. It forms the imagewise and fully variable transfer layer for the finishing foil, which thus bonds to the substrate.

Numerous different coloured finishing foils as well as hologram foils are available for print finishing. (source: Xeikon)

Improved Sustainability with ECO Toner

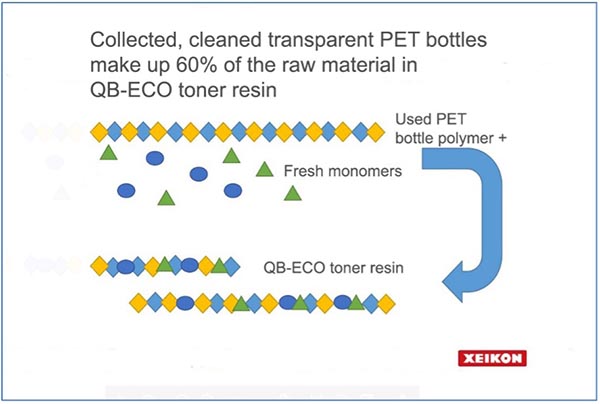

An innovative leap in the dry toner process lies in the improved sustainability that the new generation “ECO Toner” has. The advantages that the new resin used for this purpose offers during its production affect the sustainability of the dry toner process as a whole.

In the modified ECO Toner manufacturing process, around 60% of the polyester comes from previously collected, cleaned, transparent PET bottles that have been

fed through a chemical recycling process to manufacture the ECO toner resin, with the same properties, composition and purity as fossil-based resin, but with a reduced carbon footprint.

60% -weight percent of the toner resin renewable carbon is coming from collected and cleaned transparent PET bottles. (Source: Xeikon)

The resin is made even more sustainable by introducing other renewable monomers alongside the reused monomers coming from the cleaned transparent PET bottles, increasing the renewable carbon content of the resin to 66.9%.

Since the resin makes up the largest part of the toner recipe, this development has a very significant impact on the sustainability of the dry toner process. Xeikon states that by using ECO Toner, the carbon footprint of the dry toner printing process is reduced by 10%.

What Does the Market Demand?

Xeikon is introducing its innovations and inventive strength to the market at a time when the dry toner process has to assert itself more robustly than before, against other digital printing processes. They face the need for solutions in a market environment that is characterized by the demand for more flexibility in the supply of labels and packaging, shorter lead times and greater agility, as well as the shortest possible call-off times for the exact quantities needed. In this situation, for many converters, the answer lies in higher print speeds and higher productivity. With the new, faster LX3000 dry toner machine, Xeikon can have its say.

At the same time, the expansion of the dry toner process to new areas of application increases the attractiveness of the process. Users have the opportunity to serve the market with an expanded portfolio. And when entering digital printing or adding new press technology to the printshop, greater market prospects make it easier to decide on an investment in new machine technology.

Xeikon attaches great importance to improving the sustainability of the dry toner process. Greater sustainability increases the acceptance of the process in the market at a time when the idea of sustainability is becoming more and more important. For Xeikon, the newly developed ECO toner is already an important part of making the process more sustainable.

Questions of ecology require transparency in order to be able to compare technologies. Xeikon is currently working on a comparative tool that shows how large the carbon footprint of each digital printing process is. It is a comparison under defined conditions, to which Xeikon invites other printing press manufacturers and interested parties to participate. It’s a tool that enables the greatest possible transparency when evaluating the digital printing processes with regard to their sustainability.

Dieter Finna is a printing engineer with a broad expertise in the label printing and packaging industry. In his many years at Flint Group, he held various positions in the printing plate and ink business. He founded pack.consult in 2016, a platform for content marketing and packaging printing consulting.