Background

As digital printing for commercial and packaging production continues to increase, the need to inspect the print for defects before it comes off the press and into finishing or converting is becoming an essential function. While press manufacturers have integrated various levels of inspection into the printing systems, most of them are targeted at registration, color, and, in some cases, nozzle outs. However, as we see an increase in speeds and variable data printing, the need for ultra-high-speed on-the-fly content inspection is increasing.

Lots of data

Press speeds, resolutions, and the use of variable data are growing. According to Eric Worrall, Global Graphics Software VP, “Industry data rates are accelerating as press resolutions are moving from 600 dpi to 1200 dpi and speeds are increasing up to one thousand feet (300 meters) per minute quadrupling the amount of data.” Today’s presses can be up to 13 feet (4 meters) wide for packaging and industrial print applications like flooring and décor. Compound that with the use of extended gamut (ECG) inks and multi-level screening becoming more commonplace, the amount of data being sent to printheads is unprecedented.

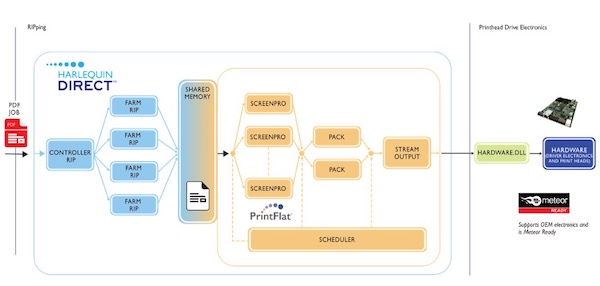

If you add variable data into that mix, it requires even more significant and costly hardware to keep up with the presses. It is creating a need for server farms to drive these presses which are beginning to look as big as the press, and adding a significant expense to a press equipment cost. Putting a supercomputer at the front end of a production system is not practical, which is why Global Graphics developed Harlequin Direct.

Global Graphics and partners have been testing Harlequin Direct with desktop class Intel i9 CPUs and have been able to process 1200 x 600 dpi page images to a press running at one thousand feet per minute with a 20-inch-wide print bar at press speed. While that is only one color, and for four colors you would require four CPUs, these are inexpensive desktop class CPUs, not expensive Xeon server class. You can expect to see presses using this new technology introduced later this year.

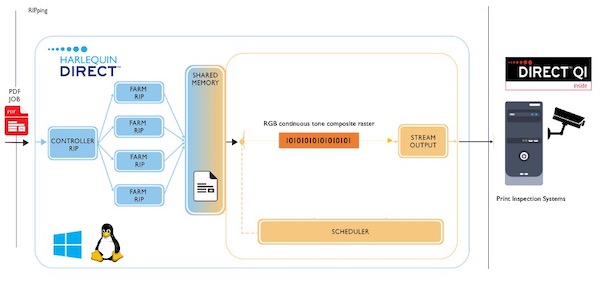

For content inspection, getting the data to the printhead only addresses part of the problem. How do you process, synchronize, inspect, and compare all of that content on the fly at press speeds? While all VIS (visual inspection solution) companies use cameras to capture the streaming content, they may need to process many different reference file formats to compare those results against. Furthermore, it requires the processing of an image of the printed page at a relatively low resolution so that what the camera sees can be compared to what a human would see. For example, the colors that emerge from the combination of tiny dots of color that are actually put down on the page to produce color. That is what the VIS is ideally looking to compare and analyze, all at machine rated speeds.

Mako

After studying this problem, Global Graphics found that their Mako SDK could be used to help address content inspection requirements where the applications are static data or offline variable data. David Stevenson, product manager for Global Graphics Smart QI, explains that “Mako’s DOM (document object model) can convert and rasterize a wide range of PDLs (page description languages), including; PDF, PS, XPS, PCL5, and PCL/XL at extremely high speeds to RGB and ensure that the rendering of those document objects are accurately captured. Mako can further analyze all of that content including pages, images, vector content, text, metadata, annotations, bookmarks and links for processing and comparison against the video stream.”

Direct QI with a SmartDFE

The Global Graphics SmartDFE suite was designed to be part of a fully automated manufacturing solution supporting Industry 4.0 telematics and MIS integration, plus connectivity with automated manufacturing lines via OPC UA. It brings together the creation of optimized print-ready PDF files; workflow and job automation to connect with enterprise IT systems; RIPping; screening; optimized image quality; and, via Harlequin Direct™, driving the print data directly to the printheads at ultra-high speeds through Meteor software and electronics or through Xitron’s Navigator DFE platform all in one powerful solution.

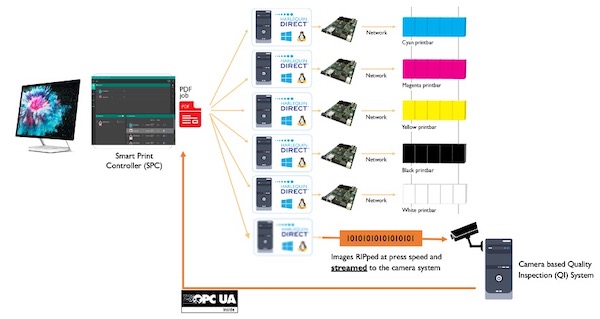

One of the SmartDFE components, Direct QI was designed to solve the ultra-high data rate inline quality inspection (QI) challenge. By combining Direct QI with a SmartDFE system, you are able to take advantage of the optimized system benefits and easily integrate the quality inspection. Since SmartDFE uses the OPC protocol, it provides industrial interoperability so it is possible to create a feedback loop from the inspection system that alerts the press which could then be directed to make adjustments, reprint pages, etc.

As seen below you could have four machines for running the different process colors, and then a fifth that is generating an RGB image from the same PDF data to generate a reference image that could be compared by the VIS. Many of the VIS systems use OpenCV, an imaging library, which can be used to compare images and through ML (machine learning) provide the systems with information that can be used to control machines and to do it at operating speed.

Designed for Integration

Smart QI is a bundle of the two products Mako and Direct QI. Mako is for static and off-line variable data. Direct QI is for high-speed inline variable data.

Smart QI is licensed based on a three-year agreement which includes maintenance and support including release updates every quarter.

There are no additional royalties including for SmartDFE customers. For use with other non-SmartDFE customers, there is simple device based licensing.

Mako is written in C++ and built for multiple platforms including; Windows 64-bit, MacOS, iOS, Android, and LINUX server, desktop, and mobile devices. It supports multiple language bindings including C# API, Java, and Python.

More to Come…

I would like to address your interests and concerns in future articles as it relates to the manufacturing of Print, Packaging, and Labels, and how, if at all, it drives future workflows including “Industry 4.0.” If you have any interesting examples of hybrid and bespoke manufacturing, I am very anxious to hear about them as well. Please feel free to contact me at [email protected] with any questions, suggestions or examples of interesting applications.