It seems like everyone is talking about “OEE” these days. I admit that, until a customer first mentioned it some five years ago, I was not aware of it. OEE is a standard way to measure the “overall equipment effectiveness” of a manufacturing process—in our case, the printing process.

OEE takes into account availability, performance and quality and has been around as a standard metric since the 1960's. The term was first coined by Seiichi Nakajima, who pioneered concepts in the efficiency of manufacturing systems.

Calculating OEE

An OEE score of 100% represents perfect production: manufacturing as fast as possible, with zero downtime with perfect quality. Of course, this is an ideal that can only be approached but never reachable in the real world.

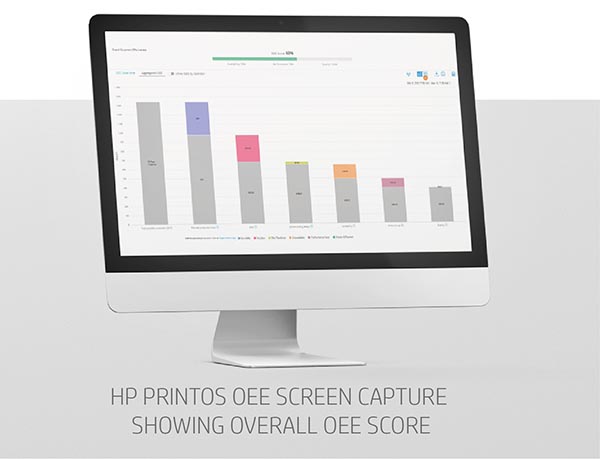

When measuring OEE, the objective is to identify and eliminate the causes of the losses (i.e. machine halts, reduced speed, changeover, breakdowns, stops due to rejected prints, reprints).

A typical OEE for offset or flexography presses is around 25%. This is due to required setup time to mount plates, set registration, set color, unload plates, etc. A typical HP Indigo press has an OEE of 35%. However, with some focus and attention, HP Indigo customers reach 50% and 60% within a few weeks, and some even get to an average of 70%.

HP PrintOS OEE Screen Capture Showing Overall OEE Score

This means, effectively, that they double the yield of their press, without investing any dollars in additional equipment. The big question, is, of course, how to accomplish this.

- First, the adage “you cannot improve what you don’t measure” is very true. More than that: often measuring something “magically” improves it. For example, if you ask your team to weigh the waste, you’ll very quickly have less waste. Therefore, measuring OEE is the first step to improvement.

- To measure your OEE, collect data from your production floor and then aggregate the data into the OEE categories. This method reveals facts and trends that otherwise you wouldn’t be able to identify. For example, one of our customers discovered that he spends 20 working hours per week bringing paper from the warehouse. Changing the paper delivery process and adding a few paper shelves near the press dramatically reduced the time to just two hours per week. This is 18 additional “freed up” hours of work for his staff each week!

- Collecting and recording the production events can be done manually, but it requires a high effort. Even worse, it’s error prone. Using an OEE tool is highly recommended, especially one that is integrated with the press and automatically records key events such as printing, consumable replacements, set-up, maintenance, etc. Note, however, that the operator will still need to manually report events like a break, or “waiting for customer approval.”

Measuring OEE may look a bit “out of context” in these pandemic days, where many printing operations are facing a decline in print volume. However, these less-busy times can be used as opportune windows of time to improve processes, increase efficiency, and get much more out of your existing presses and workforce.

To view the entire Workflow Chef series and other relevant sponsored content from HP Indigo, visit https://whattheythink.com/topic/hp-workflow-chef/