- Although over half of PSPs own a print MIS solution, many of these systems are not used to their full capacity.

- Each application and market will bring a distinct set of requirements and challenges for the business to manage.

By Ryan McAbee

Introduction

The landscape for print management software is becoming more complicated as the convergence of print applications and technology continues.As print service providers (PSPs) onboard more applications supporting a diversified set of customers and industries, it becomes more of a challenge to manage the unique requirements of those industry segments with a single business management tool. PSPs and vendors may find that traditional business management systems and existing software partners are not suitable for the expansion opportunities in tangential print manufacturing segments.

Current Use and Adoption of Print MIS Solutions

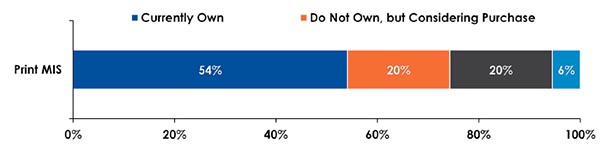

The majority of PSPs own a print management information system (MIS) solution. According to annual research by Keypoint Intelligence, the current ownership rate in the US stood at 54% for 2020. At the same time, however, adoption is only part of the story. Past research has determined that there was a high level of underutilization of the print MIS solution for many printers. Generally speaking, PSPs use the “core” functions of estimating, quoting, and job ticketing but are less likely to use some of the additional modules like scheduling, shop floor data collection, shipping, and dashboards/business intelligence.

Print MIS Adoption in the US

Source: NA Software Investment Survey; Keypoint Intelligence 2020

It is precisely these underused components that are critical for business expansion. Scheduling provides insight into production demands and capacity levels. Shop floor data collection is critical for powering reporting and reviews of key performance indicators like profitability, on-time performance, and costing. Without these fundamentals in place, adding new applications in adjacent print segments (e.g., wide format signage, packaging) is akin to making a guess without having the evidence to support it. Industry convergence forces PSPs to know their numbers.

Types of Business Management Systems

While a print MIS solution is a common software component for managing a printing business, it is not the only one. This is particularly the case if we expand into printing segments beyond commercial printing. Other potential business management tools include enterprise resource planning (ERP), product lifecycle management (PLM), and manufacturing execution systems (MES). The Table below offers an overview of the printing segments that often use this type of management tool.

Common Business Management Solutions in the Printing Industry

|

Solution |

Description |

Applicable Printing Segments |

|

Print Management Information System (MIS) |

Solution designed for bespoke manufacturing based on specific functional modules, such as estimating and accounting. The solution is order driven. |

Commercial, publication, direct mail, and in-plant |

|

Enterprise Resource Planning (ERP) |

A collection of applications to collect, store, manage, and interpret data across many business activities. The solution is order/financially driven. |

Sign and display graphics, functional, labels, folding carton, some in-plants |

|

Product Lifecycle Management (PLM) |

Connects complex supply chains from the point of ideation to creation and (in some cases) disposal/recycling. |

Textiles and apparel |

|

Manufacturing Execution System (MES) |

Tracks and documents the transformation of raw materials into finished goods. The solution is process driven in real-time. |

Corrugated converting |

The Impact of Convergence

The printing industry continues to converge. The traditional definitions of print establishments—like commercial printers—are blurring. Many PSPs now own multiple types of printing technologies and output a diverse set of products, including signage to direct mail and everything in between. Each application and market will bring a distinct set of requirements and challenges for the business to manage. For example, installation services are not common for commercial printers, but they are for certain types of signage. Will you manage local staff or outsource these services? Your current business management solution may not be able to adequately support the new functions that are needed. To ensure that you can manage the new business opportunities and lines of business, start by identifying the new expectations of your customers and the subsequent processes/tasks involved with meeting those expectations.

The Bottom Line

Entering a new market to supply printed products involves much more than just acquiring the best printing equipment. PSPs that are looking to expand into new markets and applications must first make sure that their business management system is adequate for these new printing requirements. Today’s business management system must be agile so they can adapt to support all of the necessary applications.

Ryan McAbee is a Director for Keypoint Intelligence's Production Workflow Consulting Service, which focuses on providing technology, business, and market insights to clients in the Digital Marketing & Media and Production Workflow markets. In this role, he is responsible for conducting market research, market analysis and forecasting, content development, industry training, and consulting with print service providers.