So what will the theme be for 2012? The clearest theme to emerge is that there will be themes rather than one over-riding theme in 2012.

“It will be the & drupa,” says Kodak EAMER managing director Philip Cullimore. “The media is an & world – print & apps, print & online, print & tablets, print & mobile. And, it’s not just print & other media. There’s also the combination of different print processes, where the sum equals more than the parts. It’s digital and offset.”

Transformation and transition are also emerging as themes for drupa 2012, and how vendors can help with that change through business development tools.

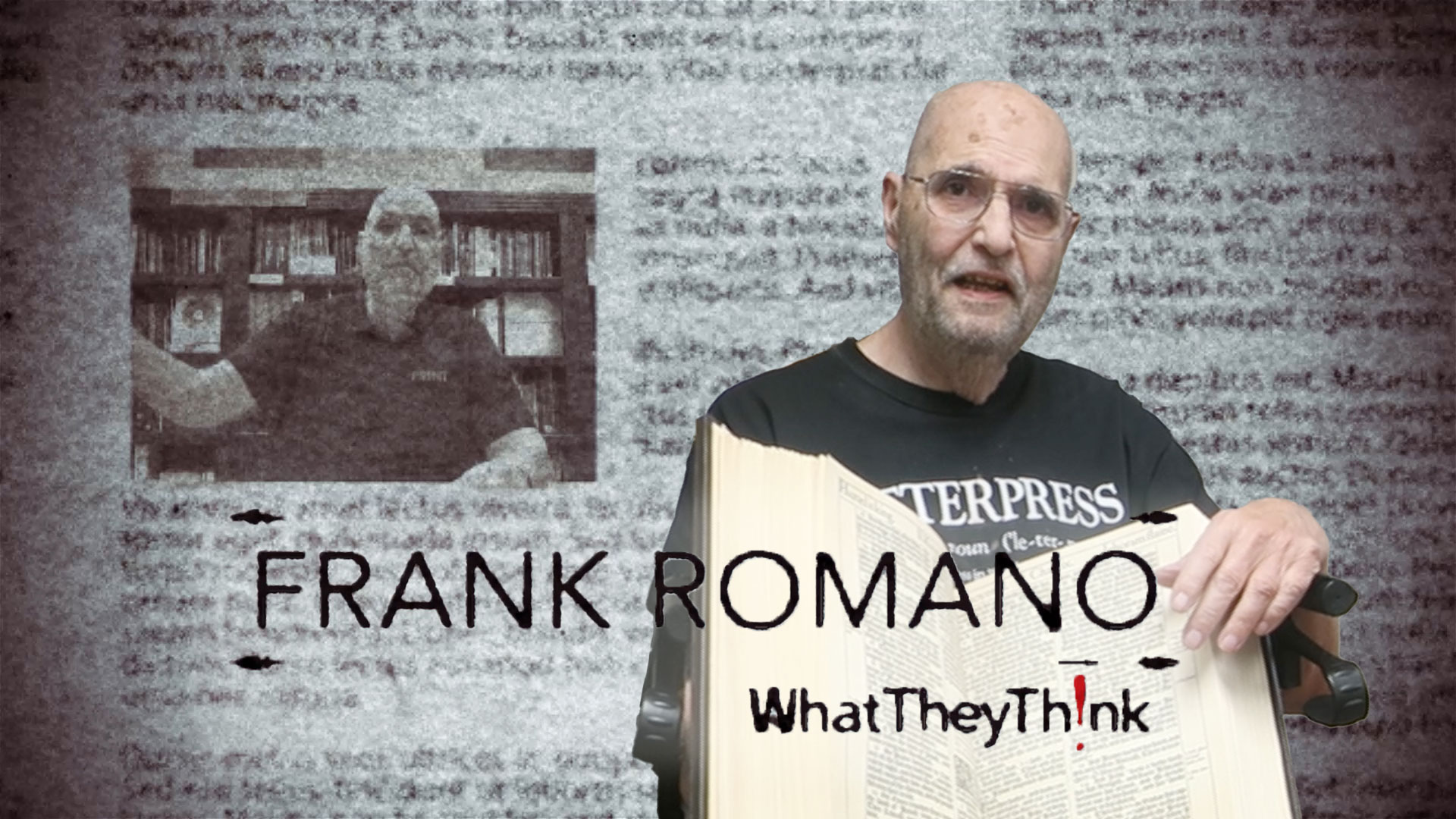

Professor Frank Romano's drupa through the ages

1972 - The small commercial press drupa

1977 - The colour electronic prepress drupa

1982 - The phototypesetting drupa

1986 - The fully-composed-film drupa

1990 - The digital drupa

1995 - The improved productivity drupa (CTP, DI presses, digital colour printing)

2000 - The press and workflow automation drupa

2004 - The JDF drupa

2008 - The inkjet drupa

2012 - The inkjet on steroids and inline finishing drupa

"At Ricoh we believe that drupa 2012 will be about transformation,” says Ricoh Europe Director of Production Printing Business Group Graham Moore. “Technology will continue to progress but the challenge for the print service provider is bringing it all together and getting the real business development support to manage change. Examples of that transformation are from offset or digital to offset and digital, from supplying just print to supplying cross media services - and the related transition from print service provider (PSP) to marketing services provider (MSP)."

Maps and guides to the new business landscape

“For printers to become marketers they need a lot of help, which is where the business development tools of the vendors become important,” says industry analyst Andy Tribute. “Historically drupa has been a technology show but it’s also about business processes and innovation ,” says Canon Europe Professional Print Director David Preskett. “We will show how our clients have innovated in business processes; visitors can get a taster that may we hope will inspire them and lead to further things.”

There is a recognition that for print to play its part in the cross-media world it has to prove that it is effective against, and with, other media. One of the phrases that will be everywhere at the show is ROMI – return on marketing investment.

HP GSB worldwide marketing director Francois Martin believes that the perception of print by brand owners is already starting to change. “It is moving from being seen as slow moving medium in competition with on-line that also creates waste to one that adds value with desired documents that create positive feeling and emotion when properly used,” he says. Alongside the increased focus on the purpose and the business of print there will, of course, be lots of the latest technology on display, as whatever application you print and whomever you produce it for, better tools are an essential way of meeting the latest challenges.

Offset stands its ground

Digital, and inkjet in particular, may have been in the limelight at the last drupa, and will be this time, but it’s important to remember despite the inroads digital print has made just how much printing is still produced using analogue processes, and isn’t ready to go digital yet either. We’re nowhere near the turning point where digital print volumes overtake offset argues Agfa Graphics Head of Product Marketing Ralph Hilsdon. “The change is coming but you will see offset standing its ground.”

The focus in offset press development has been to improve the automation, which can reduce operating costs. Much of that focus is on reducing make-ready and changeover times to support shorter runs and quicker turnaround times. It isn’t the only benefit though. Every step towards automation helps to reduce the unit cost of the printed piece, an important factor when fighting to maintain a margin and print itself needs to prove its cost-effectiveness as a marketing medium.

“We will see improvements in sheet fed offset, to the point where you can almost eliminate the operator,” predicts Andy Tribute. He believes features such as on-press measurement, will evolve to measure and control colour faster, and to be able to read the whole sheet to identify print quality defects such as hickeys. These developments will help to continue to reduce the run length at which offset is viable to a couple of hundred sheets, firmly in the territory occupied by digital today.

Reducing makeready and changeover times through automation is crucial for getting work through the press hall quicker but is only of limited use if the sheets then need to sit around for an age before they are dry enough to be handled for the next stage of production. Look out at drupa for several different approaches to eliminate that dead drying time. One approach is through UV-cured ink. The latest generation of lamps and associated inks are designed to run cool and long, promising low power consumption, longer lamp life, wider stock choice and no need for expensive cooling and ozone extraction. UV is just one option and may only be practical if you are investing in a new press. Those not in the market for a new press should check out the latest development from ink suppliers, which promise rapid setting of conventional inks in some of their latest formulas. You can bet that even if they cost more than a bog standard offset ink, in comparison to toner or inkjet their price pales into insignificance. Another example of how offset suppliers are making the process more viable for shorter and shorter runs and quicker and quicker turnarounds to fight against the encroachment of digital.

Web-offset will also see developments. “The focus is on reducing waste, labour and ultimately the cost needed to produce a given volume of pages, whether that is through bigger presses or through automation,” says Goss International Marketing Manager Greg Norris, who believes the next step may eliminate some changeovers and make-readies altogether.

This more agile form of web-offset may mean it can win some work that used to be the preserve of sheet fed presses too, proving that it’s not just analogue vs. digital but it’s also important to consider the type of paper transport employed and whether it makes sense to use sheet fed/cut-sheet or web-fed/continuous feed.

The inkjet drupa (again)

If 2008 was the inkjet drupa, then what will 2012’s predominant digital theme be? It will be the inkjet drupa, again. “2008 was the inkjet concept drupa, 2012 will be the inkjet delivered drupa,” predicts Fujifilm Europe Graphic Systems Marketing Communications Manager Graham Leeson. “On show will be more inkjet machines for many more applications.” In the past four years, inkjet has made significant inroads into the digital printing market and is set to continue.

“In 2008, high-speed production inkjet printers only accounted for about 10% of the global digital colour print volume,” says InfoTrends Group Director Jim Hamilton. “That figure is rising rapidly and by drupa 2012 will be a quarter of the total volume and by 2014 will be more than a third.”

Developments in continuous feed inkjet have been rapid with most suppliers such as HP moving from a single machine to a range of widths, speeds and capabilities. Tribute believes that the next category of inkjet presses to emerge will be for more affordable continuous feed products with a speed of 50m/m with a price tag of $500,000, extending the range of printers who will buy the devices, the applications they are used for and the volumes of print produced using this technology. But what of the cut sheet B2 inkjet machines? Leeson explains: “Continuous feed got off to a quicker start after the last show because the quality requirements and therefore technology employed is less cutting-edge than for sheet fed.”

The question is, will Fujifilm and Screen’s machines be joined by other B2 sheet fed inkjet machines? At the time of writing it was too early to call, although there will be developments. The picture that is emerging is that the next generation digital presses, which we may see at drupa 2012, will be aimed at the applications that are currently the mainstay of the market, and as such are produced on B2 sheet fed offset presses. However, just because that is the form factor of the leading litho technology, doesn’t mean that it necessarily follows that whatever replaces the B2 offset press as the printing industry’s workhorse needs to be the same in all respects except the imaging method.

Automation and integration

Regardless of the printing processes employed joining up – that is integrating – the ordering, managing, producing and distributing a job are crucial to meet demands for lower cost, more effective and faster to market printed products. Once those processes are integrated, it also makes it easier to automate them. “One key aspect of digital print that is often overlooked is its ability to be used in automated workflows,” says InfoTrends' Hamilton. Reducing operator intervention and expanding the tasks that a single operator can handle holds critical importance in today’s production environments.”

But it’s not just in production where the benefits can come from automation and integration. As run lengths reduce and the number of jobs swell administration and customer service become increasingly significant costs of each job, putting the emphasis onto upstream systems and how you deal with clients. “We will continue to see further automation in the workflow, and more integration of systems, especially beyond the walls of the business to customers and between content systems and business processes,” says Agfa’s Hilsdon.

Hybrid printing, more than the sum of the parts

There is undoubtedly competition between digital and analogue print processes. The wise visitor to drupa will investigate thoroughly the latest developments - whether it is offset’s shift to shorter runs, or digital’s migration to higher volume - which may mean that they need to reconsider their own production capabilities. At the same time, it is becoming clear that it isn’t just an either or situation but as Kodak’s Cullimore said it’s the & drupa. There are benefits of using the two technologies together. That may be in hybrid printing systems that use digital to overprint variable data onto offset, or by running both analogue and digital presses and routing the work to the most appropriate for that job.

“The transformation of printed pages to digital is not a jump from analogue, it includes blending and merging,” argues Cullimore. “For some printers it’s just not possible to move their applications totally digital, hybrid systems that use digital to customise higher-volume products, can add something to litho. Goss’ Greg Norris adds: “We see an opportunity to integrate web offset with digital print in hybrid systems.” While there may still be a battle between the two processes in certain sectors, there is also agreement that they each have strengths, and the best approach is to combine them.

“We describe the job splitting between offset and digital printing as follows: printers can use their offset press for long-run jobs,” says manroland Vice President Corporate Marketing and Communications Thomas Hauser. “Consequently, when they also have a digital printing press, their offset operations are more profitable. The workflow is the central point in a mixed production environment. We want our customers to use existing workflows with a joint metadata workflow that controls the digital printing press and finishing equipment. Thus offset users can remain in their familiar environment with the digital printing press seamlessly integrated in the offset dataflow.”

manroland isn’t alone in that. While it’s partnership with Oce may have been the first to be announced between an offset and a digital vendor it was followed by Heidelberg teaming up with Ricoh, and KBA with RR Donnelley, the former to resell Ricoh digital printers to complement offset and the latter to develop new digital printing platforms that combine KBA’s prowess for building presses with RR Donnelley’s digital and hybrid printing experience and intellectual property. There may yet be more alliances where firms that were thought of as adversaries become partners.

Many themes = many reasons to go

“To benefit from a trade show, one needs to get away from the day-to-day pressures of business and take the chance to meet people and exchange ideas,” says Canon’s David Preskett. You can see applications, you can network allowing you to share information. Big exhibitions are one of the few opportunities to get away from your business and gain a clear insight to future business ideas and innovation.”

Canon’s Preskett adds: “I think it’s difficult to call a theme. It only really becomes apparent a few days into the show when it becomes clear what it is that the visitors have come to see.“

Whether it’s automation drupa, the & drupa, the cross-media drupa, the inkjet drupa, the litho strikes back drupa, the transformation drupa, or any other drupa, the show is what you make it. To make the most of it you have to be there to experience first-hand, to form your own opinions and to take away what is relevant to your business. It’s your drupa, see you in Dusseldorf.