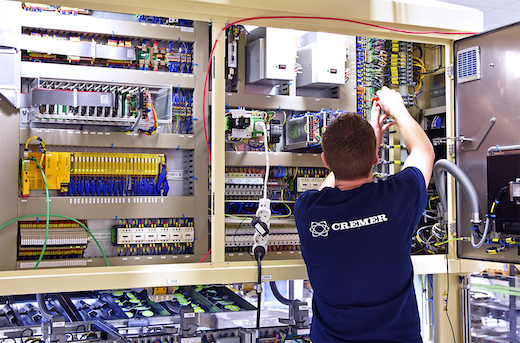

Cremer Streamlines Aftersales Service, Including Additional Personnel and Enhanced Remote Capabilities

Press release from the issuing company

Approach complements overnight parts delivery, in-house components manufacturing and customized retrofitting for company’s premium counting machines for industrial and food sectors.

Towaco, N.J. – Cremer, a leading supplier of product counting machines in the U.S. for a wide array of applications, has further streamlined its already-robust aftersales capabilities for North American customers. Among other initiatives, the upgrades expand the company’s team of sales and service professionals, and extend remote capabilities to a broader range of servicing needs.

The improvements build upon Cremer’s strong aftersales reputation – one earned, in part, because its reliable equipment portfolio is known to limit maintenance needs, often going years between even scheduled servicing appointments. The resulting minimized downtime is one reason the company’s counters quickly recoup initial investment.

For instances when spare parts are needed, Cremer offers overnight delivery in most cases, leaning upon a stocked warehouse of available components ready to ship immediately upon order receipt. Important for a segment as niche and customized as counting machines, Cremer also has the capability to self-manufacture some 90% of the parts commonly found in its equipment – including HMI components and other incorporated electronics. Not only does this in-house system best ensure parts availability – a key benefit especially given the recent pandemic-related supply chain challenges – it also helps assure that spare parts and upgrade components offer peak performance and reliability.

Cremer’s tight oversight of its aftersales program also leads to truly customized retrofitting that helps existing machines evolve to meet needs for heightened throughput and expanded product portfolios. For example, if a customer ships a product it wishes to be counted on an existing counter, Cremer engineers can investigate that product’s feasibility for that machine and, upon confirming its viability, design new vibratory plates that align with the machine’s parameters while being ideally suited for the new product.

Cremer’s aftersales services are available for its full library of equipment, including its recently introduced HQ Series, a line of compact counting and packaging machines designed for unmixed, single type or single flavor products. The servo-driven three-model portfolio provides fast, reliable and cost-efficient counting solutions for primary or secondary packaging of candy, confectionary, and chocolate, as well as non-food products such as medical parts, hardware and detergent pouches.

“Especially considering the travel and supply chain challenges many companies experienced during the pandemic, the ability to tightly control our customers’ equipment maintenance, servicing and upgrade needs is a true differentiator,” said Brian Pomponio, Business Development Manager of Cremer North America. “Our overarching approach is based on one principle: that customized machines require customized servicing, spare parts and retrofitting programs.”

For more information, visit www.cremer.com.

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free