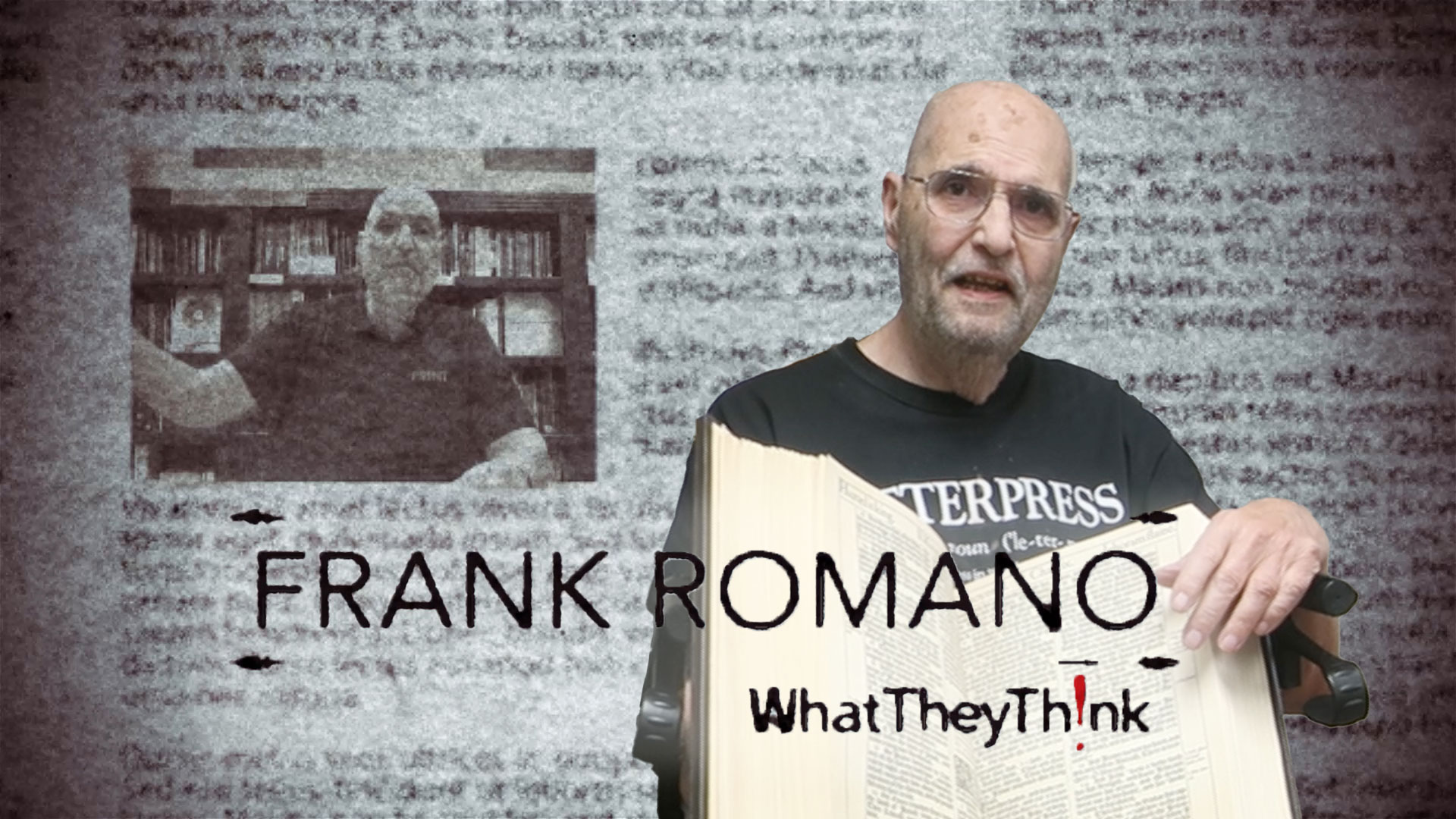

PREMIUM CONTENT

Our mission is to provide cogent commentary and analysis about trends, technologies, operations, and events in all the markets that comprise today’s printing industry. Support our mission and read articles like this with a Premium Membership.

TO READ THE FULL ARTICLE