Arden Dies Tests the UK Market with Solidplate Dies

Press release from the issuing company

A new die-making product could soon be heading to the UK market after some successful trials by Arden Dies.

Arden Dies, which has been a leader in the die-making and packaging industry in the UK for more than half a century, is running trials of its new Solidplate Dies.

The move comes after die making innovators, Marbach, which has been a partner of Arden Dies for more than four decades, has been enjoying global success with its Solidplate Dies, prompting Arden to test the UK market.

The first trials have taken place with Essentra Packaging in Bradford, who converted a 30 up RTE Pharmaceutical Carton layout, running on their Bobst Expertcut 106 PER at 8970 SPH.

Ben Nappey, Site Manager at Essentra, said: “This is a great product and we are very impressed with the results, we’ve never had performance anywhere near this before.

“Arden suggested Solidplate Dies as an alternative tooling package for us and it’s certainly delivered in terms of press performance and the potential commercial benefits and savings. We’d be keen to use more of this type of tool in the future for our multiple up layout ranges, particularly if similar run speeds can be achieved.”

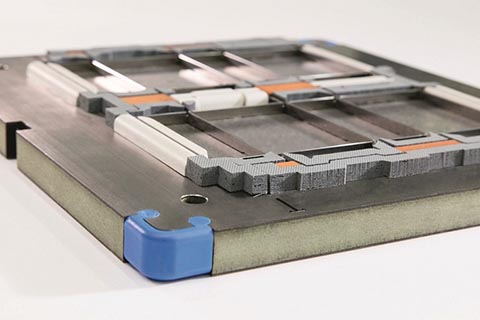

The Solidplate Die is branded by Marbach as ‘The Accurate One’ due to its dimensional stability, allowing excellent registration between engraved counter plates and die, and delivering high-quality creasing results.

As the entry level model in the field of dimensionally stable die boards, it’s affordable, high-performing and robust enough to deliver multiple re-knives.

Simon Lynch, Operations and Sales Director at Arden Dies, said: “Having supplied Performance Duramar Dies and Engraved Plates to several UK convertors, including Essentra, for many years, we are now proud to trial this relatively new product in the UK and Irish market, offering an alternative and competitive stable tool option to carton convertors.

“Our partners Marbach have enjoyed global success with Solidplates, so we are confident there will be a real appetite for this alternative tooling solution.

“Trials are ongoing with several more UK-based customers, and if they continue to be as successful as we’ve seen so far, then we will be investing further in the manufacture of Solidplates at our purpose built factory in Greater Manchester enabling us to deliver such tooling in the shortened times scales demanded by the market.”

The Solidplate Die.

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free