Flexible Packaging: 100% Inspection System Takes Quality Control to the Next Level

Press release from the issuing company

Plastics Packaging Technologies monitors the production of flexible packaging at its site in Columbus, Ohio (USA), with the PrintSTAR 100% inline inspection system from ISRA VISION.

More brand owners than ever are relying on the striking impact provided by flexible packaging in order to further solidify their presence at the point-of-sale. Despite the high demand for innovative packaging solutions, manufacturers still face stiff competition, as the requirements placed on high-quality printed products are constantly increasing. In order to meet the growing customer demands, US packaging manufacturer, Plastic Packaging Technologies (PPT), relies on the PrintSTAR 100% inline inspection system from ISRA VISION, the world’s leading provider of inspection systems.

With great passion and experience, the team in the print department at Plastic Packaging Technologies produces flexible packaging for foods, snacks, and pet food. While this has always been the case, the path to defect-free print quality has improved significantly over the years. In the past, eagle-eyed and highly focused operators would constantly view a monitor screen to catch and identify print defects at an early stage. This approach was not reliable as the operators were often burdened with other tasks. In order to modernize the quality control procedures from offline to inline, the decision was made to integrate an automatic 100% vision inspection system. The inspection should retrofit properly into their Uteco press, but also would need to be economical. As part of their selection criteria, PPT also considered other factors, such as the requirement to properly classify defects, as well as user-friendly operation and hassle-free installation.

Impressive properties of the inspection system

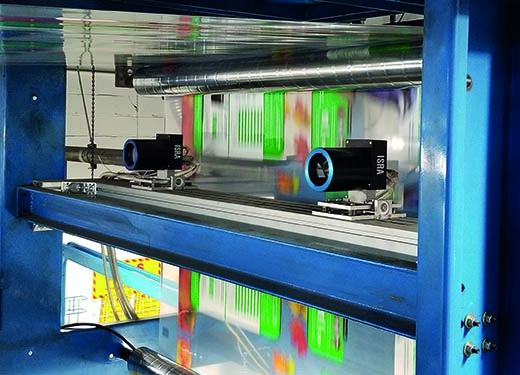

During the search for a suitable system, PPT discovered the extensive product portfolio from ISRA VISION, the leading supplier of inspection systems, and decided to procure the 100% inline inspection system, PrintSTAR. The system, that is d deployed around the world, guarantees complete 100% inspection, even at full speed, in order to achieve error-free printing results with proven reliability. The easily configurable dual-camera system was installed just after the last printing station making excellent use of the available space.

By deploying high-resolution, embedded line cameras combined with special and ultrabright LED lighting, the PrintSTAR system detects and classifies both unique and recurring defects in real time. The smart all-in-one camera with embedded color camera technology combines sensor, processor and interface in a compact and robust enclosure. Thanks to its high resolution of over 8 megapixels and its extremely fast frame rate, the embedded camera delivers image data with the very highest level of detail. The intelligent inspection system not only reliably detects all defects, but also ensures that predetermined standards and tolerance limits are adhered to by immediately comparing the print result to the customer’s PDF file. At Plastic Packaging Technologies, the new system helped the team discover many print misregistrations and omissions.

High level of acceptance for the inspection system

The inspection system was ready for operation shortly after installation. The machine operators and production managers were quick to approve as the system is not only easy to operate but ensures maximum productivity within a short period of time. The reliable capture and identification of defects helps the print department meet their quality goals. In addition, the operators now have more time to dedicate to other printing tasks and quality control measures, now that they are free from depending on a monitor to personally catch a problem. If a relevant defect is discovered on the printed film, the inspection system automatically triggers an alarm. Remaining relevant defects are recorded and classified for analysis. The data is used to examine the production process and decide on maintenance and production workflow improvements.

Deploying the PrintSTAR inline inspection system also offers other crucial benefits for the user: The option of modifying an acceptable defect size enables the operator to decide if and when to stop the press to rectify a defect, thus preventing unnecessary downtime in production. PrintSTAR helps to reduce waste by immediately informing operators to the start of a problem so it can be quickly rectified.

Fewer complaints lead to cost benefits

The PrintSTAR inspection system enables the customer to precisely classify different defects by size, color or even catagory, such as streaks, splashes, register defects and color deviations. Customer directives and tolerances can thus be determined for every print job, while limit values can be entered in a job-specific profile. Defects which exceed the tolerances are displayed to the operator, enabling them to intervene in the printing process to prevent waste and avoid complaints. This enormous improvement at PPT can be seen in concrete data, with the cost associated with customer complaints dropping over 80% between 2019 and 2020. In addition to the cost benefits, the company also benefits from an improved reputation amongst its customers – a factor which is ever more important in light of the stiff competition in the printing sector.

Summary

Due to its wide range of inspection solutions, ISRA has an appropriate inspection system for every printshop. And there are no compromises when it comes to ISRA Vision system components or installation and service support. The simple system operation and thorough on-site training combine to ensure PrintSTAR inspection systems can be integrated and operational within a few days.

PrintSTAR users benefit from a reliable vision inspection system proven to provide maximum process efficiency for their printed and coated webs. PrintSTAR records all events enabling analysis of the production process, and providing operators and supervisors the ability to ship the highest quality product to their customers. Using an ISRA inspection system will reduce print rejects and complaints, thereby lowering costs. Less material waste, improved quality and time savings will also ensure a quick return on investment.

- Inkjet Integrator Profiles: DJM

- Spring Inkjet Update – Webinar

- Security Ink Technologies for Anti-Counterfeiting Measures

- Komori unveils B2 UV Inkjet

- Keeping Nozzles Fresh with Flow

- Komori to Unveil the J-throne 29 Next Generation Digital Press at drupa 2024

- Inkjet drives convergence of transactional and graphic arts applications

- The Inevitability of Technology Shifts and How to Communicate with Credibility

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free