Packaging Producer Plastica Proves You Can ‘Have It All’: Lower Costs, Higher Productivity, AND Higher Quality

Press release from the issuing company

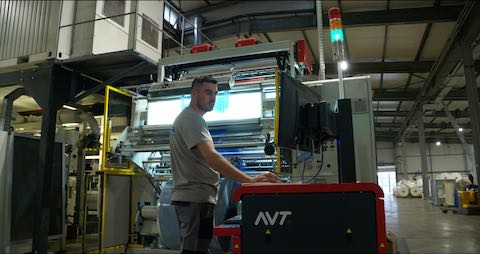

With AVT print inspection solutions, Plastica cut production costs by 25% and raised productivity by 30%.

Hod-Hasharon, Israel – Hats off to SC Plastica SRL, a Romanian packaging specialist coming up to its 30th year, for its long history of visionary investments.

Founded as a family company in 1992 by Ioan Holdis and his wife, Plastica originally focused on producing polyethylene packaging. Then, as the market developed and Plastica won large retail jobs, the Holdis family realized they would need to invest in state-of-the-art printing equipment. Several rounds of major investments between 1997 and 2013 were instrumental in propelling the company toward its current focus on producing packaging for the pharmaceuticals, food and agricultural products industries.

Looking beyond printing capabilities

Having acquired some of the most advanced printing and laminating solutions available, Plastica soon saw that its printing equipment lacked vital capabilities in the areas of print process control and error detection, tracking, selection and marking. Ioan Holdis, Plastica’s General Manager, says they decided that the next investments would have to bring them those missing capabilities.

Fast-forward to 2018, when the Plastica management team decided to make new investments, this time, to help control and optimize the entire production process. A review of the market soon drew Plastica’s attention to AVT, a leader in print process control, quality assurance, and press control.

At that time, the company added an AVT Argus Turbo HD 100% Inspection system to its existing Comexi printing press, to detect, record, mark and eliminate defects in the production process.

Dramatic bottom line benefits

Soon after installation, the AVT system’s advantages were strongly apparent. Mr. Holdis says: “With this easy-to-operate system, we were able to reduce production costs by 25%, increase productivity by 30%, and also reduce preparation time for all jobs.”

The clear benefits of the AVT Argus Turbo HD installation prompted Plastica to invest in additional AVT solutions. First, Plastica added AVT’s Workflow Link to connect its printing and finishing equipment. Then, it installed the AVT Apollo Multi-Stop inspection and waste control solution.

“Through these AVT solutions, we eliminated all the faults we had in the production process. As a result, customers are now 100% satisfied with the delivered products,” notes Mr. Holdis.

“We now have 100% print inspection and 100% error detection. With these advantages, we are able to produce more, and we have completely eliminated the risks of non-compliant products.”

Ultimately, the printed film rolls are delivered to the customer without any defects.

“With AVT, we have managed to deliver the perfect package and achieve 100% customer satisfaction.” concludes Mr Holdi?.

Watch this video to see how Plastica has done it all, with AVT.

A word about Plastica’s AVT solutions:

The Argus Turbo HD automatic 100% inline Inspection, AVT’s flagship solution, delivers a unique combination of 100% high-resolution print inspection and superior zoom process control, to detect imperfections in real-time.

AVT’s Workflow Link is the link between printing and finishing. It automatically stops the rewinder at the relevant defect location for fast and efficient waste removal, to ensure shipment of defect-free material.

The Apollo Multi-Stop is an inspection and waste control solution offering unprecedented rewinder workflow integration and efficiency at both high resolution and high speeds.

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free