At Pack Expo, IMA DAIRY & FOOD to Highlight Multilane FFS Machines for Sachets and Stick Packs, Among Other New Solutions

Press release from the issuing company

New M-Flex Series of multilane form-fill-seal machines offer single-roll operation for expanded printing choices; New format flexible Indexing Platform for pre-formed cups; P-Series of portion pack machines combine precision, speed and ease of use.

IMA DAIRY & FOOD, whose equipment solutions comprise the long-established brands Gasti, Hamba, Hassia and Erca, will introduce new and recently enhanced packaging machines at Pack Expo, September 23-25 in Las Vegas. At Booth C-3200, the equipment provider will debut its M-Flex series of multilane form-fill-seal machines, its EFS – a new fill and seal machine for pre-formed cups, as well as two updated units in its P-Series line of portion pack machines.

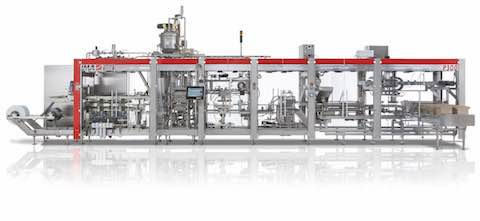

Hassia’s form-fill-seal (FFS) M-Flex Series F600 Sachet Machine produces four-sided sealed sachets at a speed of up to 80 cycles per minute, and on as many as 16 lanes. Among other differentiators, the F600 offers single-roll functionality, an improvement over two-roll formats. The units run a single wide roll, which is located at floor level for easy changeover and front-and-back sachet registration – an option offering more printing choices than traditional two-roll machines. The F600 can handle rolls as wide as 1,200 mm with a diameter of 800 mm, which can yield up to 16 hours of run time between roll changes; the result is significantly reduced downtime and boosted productivity.

The F600’s careful product handling places a premium on quality assurance, and its CIP and SIP-suitable dosing units can be adjusted per specific product requirements. Exemplary filling accuracy and hygiene standards are assured, and the hermetic pack seal produced by the F600 is secure yet easy to open for consumer convenience.

The F600 is also flexible: A range of pack designs are possible, and sizes can be configured to align with production capacity. The machine’s control concepts are highly versatile, and include opportunities for integration with customer-specific systems. The unit can handle all common packaging materials suitable for heat-sealing.

At Pack Expo, Hassia also will showcase the other member of the M-Flex Series, the S600 Stick Pack Machine, a multilane FFS module for the production of three-sided stick packages. With a typical processing speed of up to 42,200 stick packs/h, the S600 can be designed to comply with customer/product-specific requirements.

Hassia also will showcase the P500 Portion Pack Machine, part of its P-Series line of FFS portion pack equipment. Capable of handling web up to 590mm wide at forming depths up to 40mm, the high-performance P500 is suitable for a broad variety of cup designs and materials, including PS, PET and PP. The unit offers maximum accuracy, precise product cutoff and gentle product handling.

A key benefit of the P500 is its use of comparably less packaging material. This is due to a combination of attributes, including its use of forming material of minimal thickness to avoid overpackaging; minimal punch waste from the low-waste punch unit; and volume-saving overlapping packing configuration for boxes and trays. Depending on the specific product, the P500 can achieve speeds up to 108,000 cups per hour.

The P-Series of portion pack machines also includes the P300, and both units come into Pack Expo sporting new enhancements. The P300 features a new frame and guarding package for easier machine accessibility, and both the P300 and P500 offer hygiene levels up to FDA-filed, low-acid aseptic. Both also incorporate a new “cell board conveyor” discharge that controls round cups through case packing.

Erca will showcase the EFS, the recently developed new format flexible indexing platform for pre-formed cups. Utilizing new technology enhances the available options and ease

of operation and maintenance procedures. Modular in design with stainless steel construction and servo-operations, it allows for flexibility with filling stations, pre-fill and post fill for wet or dry ingredients. The chainless solution for cup transportation enables format flexibility and precision index positioning throughout the machine.

Capable of filling cups up to a diameter of 130mm, the EFS filling and sealing machine is suitable for a broad variety of products such as yogurt, fresh cheese, white cheese (curd), cottage cheese, single and multilayer desserts, aerated mousse products, deli salads, dips, dressings, hot filled sauces, soups, jams, fruit purees, tomato paste, sweet spread, baby food, pet food, etc.

Key benefits of the EFS are the format flexibility (quick release, tool free), the chainless drive (no chain stretch, no regular adjustment, less cup cassettes), the modular design and construction, the recipe functionality, the multi-fill possibilities (over track or remote fillers), and its improved hygiene options (UVC, Pulse light, H2O2). The machine will be available in hygiene levels Clean or Ultra-clean.

- March 2024 Inkjet Installation Roundup

- Inkjet Integrator Profiles: Integrity Industrial Inkjet

- Revisiting the Samba printhead

- 2024 Inkjet Shopping Guide for Folding Carton Presses

- The Future of AI In Packaging

- Inkjet Integrator Profiles: DJM

- Spring Inkjet Update – Webinar

- Security Ink Technologies for Anti-Counterfeiting Measures

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free