New On-Line Service Calibrates Inkjet Presses in Minutes

Press release from the issuing company

- Unveiled at Hunkeler Innovationdays, the www.printflat.com portal enables presses to be calibrated with a simple upload

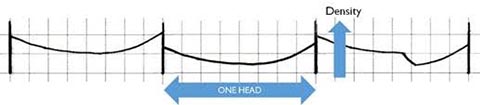

- Powered by PrintFlat™ technology that smooths out printhead non-uniformity or banding

Cambridge UK – PrintFlat™, the ground-breaking screening software that mitigates banding in inkjet output, will be unveiled as an on-line service for press vendors and their customers at Hunkeler Innovationdays.

Developed by Global Graphics Software, www.printflat.com uses PrintFlat technology to generate a customized calibration that will mitigate the banding that occurs when a print-bar is first built and also as inkjet heads begin to wear or are replaced. Users of the service simply upload a scan of the print bar to the web site via their user account, and PrintFlat works behind the scenes to generate a correction that can be applied directly to the press by the ScreenPro™ screening engine.

Visitors to the Hunkeler Innovationdays will be able to see a demo of www.printflat.com in operation.

Martin Bailey, the chief technology officer at Global Graphics Software, says, “PrintFlat.com introduces a step by step process for calibrating an inkjet press. It can work with any press that has the ScreenPro engine installed. That means that any press vendor and their customers can benefit because ScreenPro can be applied to any print industry workflow, either to a press that is already on the market, or one that’s still on the drawing board. It can be used with any RIP software and any combination of inks, substrates, printheads and electronics.

“So just as you would apply color management to your press, now vendors and their customers have a process for applying calibration that mitigates reduces non-uniformity across the web, which can be difficult and expensive to correct mechanically.”

Ellerhold AG, the market leader in Germany for indoor and outdoor advertising with an approximate 70% share of the German billboard market, is using ScreenPro™ with PrintFlat™.

“When the quality was ‘not passable’ for difficult jobs, for example images with lots of blue sky” comments Maximilian Ellerhold, CEO, Ellerhold AG, “it is now very acceptable, even for the most difficult jobs. Any residual visible banding has been removed. We’re now achieving 100% customer satisfaction and have increased our market share of outdoor advertising products in digital printing.”

ScreenPro™ is an ultra-high-speed screening engine tuned to smooth out imperfections in inkjet output and, in addition to reducing banding, addresses chaining and mottling by applying Advanced Inkjet Screens. ScreenPro is the recipient of several industry accolades such as the InterTech Technology Award in 2018, an Angel Award by Image Reports magazine, and featured in the top ten technologies of 2018 by Sean Smyth writing in Digital Labels and Packaging Magazine.

ScreenPro with PrintFlat technology reduces non-uniformity, commonly known as the inkjet smile.

Global Graphics has a long history in screening innovation dating back to its patented FM or stochastic screening technology of the 1990s. In the age of digital printing, and inkjet in particular, Global Graphics has developed new screening technologies from the ground up in response to press manufacturers’ concerns about image quality in single pass inkjet applications.

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free