Printer Manufacturer Leibinger Expands in France

Press release from the issuing company

Partnership with French printing specialist Capcod strengthens service in France

Tuttlingen – In view of offering quick service to its industrial customers in France, German printer manufacturer Leibinger is establishing a service network in the neighboring country. New on board is Capcod, a printing specialist based in Montreuil. In the future, the company will be responsible for taking on service assignments in the Greater Paris area.

Especially in the Paris area, the industrial heart of France, it was important for Leibinger to be able to offer outstanding service to all its customers with top-trained experts. “Our products are now established in numerous companies in the Paris area. Operators of complex production environments expect not only reliable printers, but also long-term support from specialized service technicians,” maintains Günther Leibinger, Managing Director of Paul Leibinger GmbH.

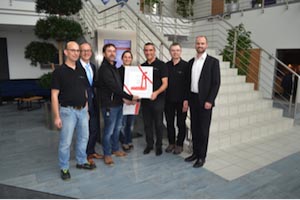

With a handshake into a common future: French printer specialist Capcod is now a LEIBINGER certified partner (from left to right: Achim Trivigno, Alexander Deuchert, Wolfgang Pfindel, Aurélie Clemenceau, Emmanuel Desfond, Vincent Dosière, Patrick Quentin).

Since Leibinger does not have a subsidiary in France, it trains partner companies in the use of their printer technology. “We look forward to working more closely with Capcod, a printing specialist based in Montreuil near Paris.” Capcod is privy to the secrets of Leibinger technology and will help industrial companies in France integrate the printers from the Black Forest manufacturer into production environments and to offer responsive service on a daily basis. Capcore receives support from Encore, a Lyon-based printing specialist that is already a partner in Leibinger’s service network.

“I see excellent opportunities to establish German workmanship in France.”

The heart of Leibinger printers is the continuous inkjet (CIJ) print head. 120,000 drops of ink shoot out of a tiny tube opening every second and fly through a high-voltage field. During printing, the field charges individual droplets. They change their trajectory, land on the product surface and dry within one second.

The remaining drops fly into a second tube opening and circulate in the system. “The training sessions in Tuttlingen were an opportunity for our employees to develop detailed understanding of the printer technology,” says Emmanuel Desfond, Managing Director of Capcod. “Leibinger is one of the pioneers in CIJ technology. I see excellent opportunities to establish this German workmanship in France.”

Capcod technicians complete their training in Tuttlingen

To receive certification, service engineers from Capcod took part in in-depth technical training in Tuttlingen. Specialists from Leibinger familiarized the technicians with the technological secrets of the JET3 up and JET2 neo – printers that use flying ink drops, for example, to apply the use-by dates to beverage cans and keeping up with conveyor speeds of up to 10 m/s.

Capcod technicians learned how to maintain the highly sensitive technology, how to integrate the devices and their software into production lines, how to work the printers together with robots, and to become part of automated Industry 4.0 production landscapes. This was followed by theoretical and practical final tests, which all Capcod technicians passed with flying colors.

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free