All Color Doubles Their Capacity with Heidelberg’s "Push to Stop" Speedmaster XL 106-6+L

Press release from the issuing company

Kennesaw, Ga. – All Color, a family owned and operated print shop in Deer Park, New York, recently replaced their former sheetfed presses with the Speedmaster XL 106-6+L with “Push to Stop” technology from Heidelberg.

The Secret to All Color’s Success

After maximizing their capacity with two older sheetfed presses, All Color decided to make the switch to a Speedmaster XL 106-6+L in order to lower costs and drive growth. Since installing the press in May 2017, All Color has been able to increase the size and capacity of the shop.

“Providing high quality print jobs means having a high quality press,” said Steven Bogue, President of All Color. “Within the past 3 months, we’ve been pushing the press. As far as productivity, I expect to just hang and bang plates, changeover jobs within 3 or 4 minutes, and constantly produce 18,000 sheets an hour — just this past month we have reached 2 and a half million impressions.”

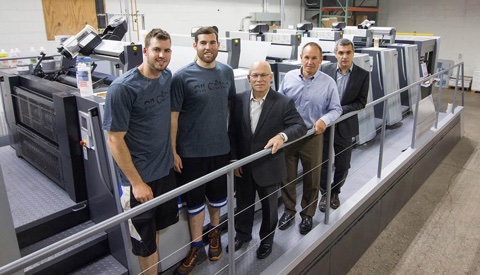

(Photo: from left to right: Will Bogue, VP of All Color; Steven Bogue, President of All Color; Marty Moran, Regional Vice President at Heidelberg; Dan Maurer, Vice President of Digital Product Management at Heidelberg; and Jordi Giralt, Director of Strategic Accounts for Primefire at Heidelberg with All Color’s Speedmaster XL 106-6+L with “Push to Stop” technology)

(Photo: from left to right: Will Bogue, VP of All Color; Steven Bogue, President of All Color; Marty Moran, Regional Vice President at Heidelberg; Dan Maurer, Vice President of Digital Product Management at Heidelberg; and Jordi Giralt, Director of Strategic Accounts for Primefire at Heidelberg with All Color’s Speedmaster XL 106-6+L with “Push to Stop” technology)

Reducing makeready times from 8 minutes to 3 minutes, All Color is able to handle even the most complex job changes at the fastest speeds possible. Thanks to Prinect Inpress Control 2, the Speedmaster XL 106 delivers the first measuring results in less than 30 sheets and the run is ready to start in less than 1 minute.

“Inpress Control is the greatest thing in the world — I would never buy a machine without it,” said Bogue. “It’s given us a great control of consistency that allows us to know what we are going to produce day in and day out — this has really led to our success.”

Equipped with the latest Push-to-Stop technology, the Speedmaster’s jobs are autonomously changed over without operator intervention and will continue to print until the operator interrupts it. The Push-to-Stop technology is made possible with Prinect workflow in combination with Intellistart 2, a new unique integrated software system for effective job preparation, which greatly reduces the number of operating steps during a job change.

The Most Automatic Equipment

All Color is a complete Heidelberg shop equipped with a POLAR cutter, Suprasetter CtP, Prinect workflow, Stahlfolder TH 82 and TH 66, Speedmaster SM 102, a Speedmaster XL 75, and uses Heidelberg Saphira Consumables.

“Using Heidelberg’s consumables ensures that when we put a job on, it will be correct,” said Bogue. “Our consistency with Heidelberg Saphira Consumables: ink, fountain solution, wash-up cloths, alcohol replacement, and proofing paper, always remain consistent.”

Being a complete Heidelberg, fully automated shop, All Color is at the leading edge of the most productive and efficient print shops in the industry.

“We’ll continue investing in the most automated equipment because it allows us to continue to decrease costs for our customers,” said Bogue.

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free