Long KBA Rapidas in demand for sophisticated packaging and commercial work

Press release from the issuing company

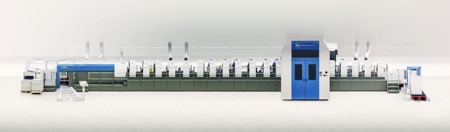

High-tech presses with up to 19 printing and finishing units

Back in 2012, it was still quite a sensation when KBA announced the installation of a Rapida 106 with 19 printing and finishing units at Amcor Tobacco Packaging in Switzerland. In the meantime, investments in medium-format sheetfed offset presses with 10, 12, 14 or more units are no longer so unusual. And that is true for both packaging and commercial printers in many parts of the world.

In 2013, for example, KBA delivered a 10-colour Rapida 106 in a double-coater configuration, i.e. 14 printing and finishing units in total, to a Russian packaging printer. In that same year, the packaging company Yuri Gagarin in Plovdiv/Bulgaria purchased a similarly configured press with an additional facility for cold foil transfer. A further 14-unit Rapida went on stream in 2015 and is now producing high-quality covers for the Appl Group in Wemding. With four printing units and a drying tower ahead of perfecting, followed by six further printing units and a combination of drying, perforating and coating towers before the final extended delivery, it is almost 99ft (30 m) long.

USA: Long is beautiful

Long presses are even more popular in the USA. In 2014 a packaging printer in Massachusetts received a Rapida 106 with a total of 15 printing and finishing units. The configuration with ten printing units, drying tower, coater, two further drying towers and a second coater is geared to high-quality inline finishing, as is the case with almost all long presses. The company has already been using an almost 131ft (40 m) long large-format Rapida with eight printing units, two coaters, three drying towers and a triple-length extended delivery, i.e. 13 printing and finishing units, for several years. Two sheetfed offset presses with a total of 28 units in one printing plant – that is indeed something special, even today.

The next long Rapida 106 from KBA-Sheetfed Solutions will already be setting off across the Atlantic soon. The press comprises six printing units and a coater plus drying tower before the perfecting unit, six further printing units, double-coating facilities with two intermediate drying towers and a three-section extended delivery, and is to be used to print commercial and advertising products for a print group with global operations. With its 18 printing and finishing units, the latest addition to the list of long Rapidas is almost the length of the legendary 19-unit press at packaging specialists Amcor in Switzerland.

These extraordinary configurations underline the outstanding competence of KBA-Sheetfed Solutions when it comes to complex sheetfed offset installations. These are not presses “off the shelf”, but rather highly automated production systems which are tailored precisely to the requirements of a particular application and enable the user to remain successful with customer-oriented solutions in a competitive market.

- Inkjet Integrator Profiles: Integrity Industrial Inkjet

- Revisiting the Samba printhead

- 2024 Inkjet Shopping Guide for Folding Carton Presses

- The Future of AI In Packaging

- Inkjet Integrator Profiles: DJM

- Spring Inkjet Update – Webinar

- Security Ink Technologies for Anti-Counterfeiting Measures

- Komori unveils B2 UV Inkjet

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free