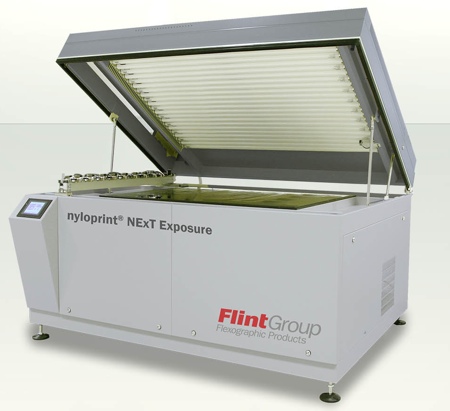

Flint Group Presents nyloprint® NExT Exposure for Letterpress Printing Plates

Press release from the issuing company

UV LED Exposure Technology for superior reproduction and production consistency

Flint Group’s innovative exposure technology, nyloflex® NExT,has been globally established for flexographic printing and offers a variety of advantages to the user. It shows outstanding results in the reproduction of flexo printing plates and significantly improved printing quality. For flexible packaging, it enables an excellent ink transfer, particularly in solids. In corrugated printing, a considerable reduction in fluting can be observed. nyloflex® NExT technology provides high reproduction quality and long-term stability. Moreover, all the advantages of Flat Top Dots and surface screening can be utilised.

Now with the new nyloprint® NExT technology, Flint Group Flexographic Products launches an exposure unit for letterpress plates, which is targeted to the security and banknote printing as well as the high-end segment of labels, tubes, cups and can printing.

The innovation is based on the latest generation of UV-A LEDs (> 250 mW/cm²), which allow a more precise image reproduction of the finest relief elements and gradations. Compared with conventional light sources, the high-power LEDs enable a virtual 1:1 copy of the digital data onto the printing plate, thus optimising the reproduction accuracy of the digital data. The exposing speed of the LED bars can be customised to specifically define dot shape and shoulder angle. Additionally, the finest highlights and open shadows increase the image contrast.

The constant UV output of the UV-A LEDs during the complete life cycle of the nyloprint® NExT exposure results in among the highest long-term repeatability, especially for rework. In this application, it shows clear advantages against the conventional tube exposure as well. The temperature control of the exposure bed ensures consistent production conditions. The new exposure unit is suitable for processing every high quality photopolymer letterpress plate up to a maximum size of 1200 x 960 mm (47.2” x 37.8”).

The new technology can be used for all digital letterpress plates, regardless of plate thickness and format. It is compatible with all standard prepress and HD software and can be easily implemented into the existing digital workflow.

This innovation has been presented for the first time during the SDW (Security Document World Conference) from 21 to 23 May 2013 in London. Furthermore, interested customers can convince themselves of the nyloflex® and nyloprint® NExT Exposure technology by visiting Flint Group Flexographic Products’ Technology Centre in Stuttgart (Germany).

More information about Flint Group can be found on the internet at www.flintgrp.com or contact [email protected].

WhatTheyThink is the official show daily media partner of drupa 2024. More info about drupa programs

© 2024 WhatTheyThink. All Rights Reserved.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free