While some analysts indicate that digital textile printing only comprises about 4% of the global market now, with adoption much faster in Europe and Asia than in North America, it’s a large and dynamic market with lots of exciting new developments.

I recently came across an Israeli startup founded in 2015 that is poised to add significant value to the on-demand production of a wide variety of textile-based products. Twine, who will ship its first beta machine in February 2018, enables digital coloring of thread, where the color penetrates the fiber itself.

Today, thread and yarns for a variety of uses is dyed in bulk. This requires that cut-and-sew, embroidery and knitting operations maintain large thread inventories. If they underestimate the quantity required for a project, it results in delays and penalties. If they overestimate—and typically they will order 5–10% extra–it results in inventory with its associated costs and inventory obsolescence risks. Plus, states Yariv Bustan, Vice President of Product and Marketing for Twine, “Conventional textile dyeing has significant negative environmental impact. Textile dyeing is responsible for 20% of water pollution globally, according to the World Bank. Conventional processes use a huge amount of water; in fact, the equivalent of the entire volume of the Mediterranean See is polluted every two years.” While Twine won’t be able to impact all of that pollution, it offers another step along the way to reduce the environmental impact of the textiles industry.

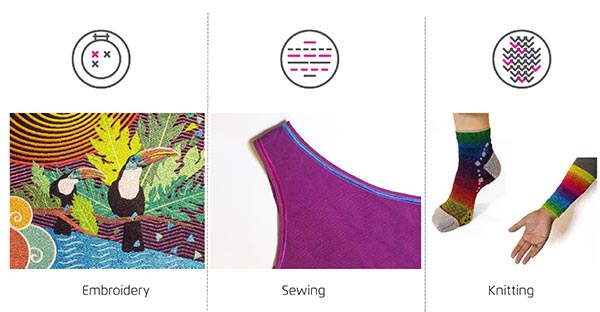

What Twine is offering is not only on-demand dyeing of raw and off-the-shelf white thread in the desired color and in any required length, but the ability to incorporate multiple colors into a single strand (and spool) of thread. Imagine a multi-color embroidery project. Today, this requires a multi-head embroidery machine or multiple passes with a single head, and the process has its limitations. With digital coloring, the exact amount of thread required for each color can be calculated in advance, and the thread can be placed onto a single spool for single-pass multi-color embroidery. This enables complex patterns that were impossible to create in the past. And it is applicable not only to embroidery, but to sewing and knitting as well. The company is currently focused on polyester threads, but one could imagine that will be expanded in the future.

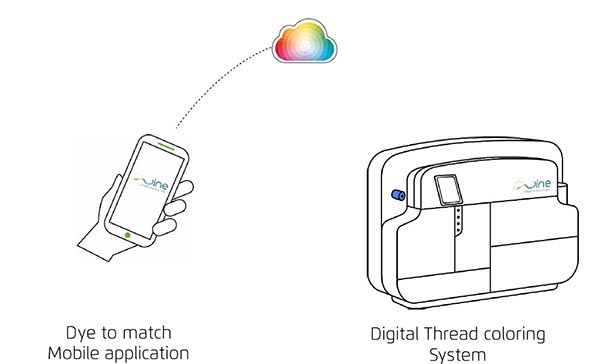

Twine will also offer a digital dye-to-match mobile app. This brings a process that would normally require a lab environment into the hands of production professionals. Users simply use the app to take a picture with a small, business-card-sized calibration card. The resulting data is sent to a cloud-based algorithm resulting in the identification of the exact color and the recipe is sent to the digital thread coloring system, all this in less than 30 seconds. No fuss, no muss. No water usage or pollution. In effect, this moves the dye house In-house, eliminating a step in the supply chain and helping improve time to market as well as reducing transportation costs since ordering traditional thread can take anywhere from two to eight weeks. The system uses proprietary digital ink with a base of cyan, magenta, yellow and black (CMYK). The plan is to make custom colors or gamut expanding colors available as well. Colorants are certified OEKO-TEX 100 Product Class 1 and Intertek Grade 5.

Twine anticipates its digital thread coloring system will be commercially available in early 2019, with its formal launch at ITMA 2019.

For more information, visit www.twine-s.com, or watch these informative videos.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free