Graph Expo 08 turned up some totally unexpected tidbits.

Graph Expo 08 turned up some totally unexpected tidbits. As I rounded the corner on one of the aisles, I nearly tripped over an old Phillipsburg inserter proudly on display. These are pieces of equipment that you can't kill, mostly can't use, and generally have tucked away in a warehouse under a tarp because there are much newer, "smarter" inserters out there.

But wait, one of the most basic tenants of "going green" is to reduce, recycle, or

reuse the things you use everyday. Sometimes we forget that the simplest solutions can be to reuse something rather than to try to figure out a way to recycle it on replacement.

Larry Miyasaka, Clear Image Technologies

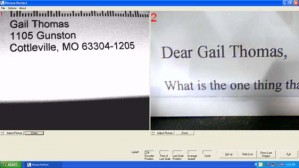

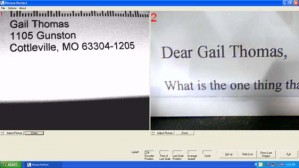

Larry Miyasaka, Clear Image Technologies, gives new life to old inserters with an elegant solution that includes cameras and a computerized matching system. The match system can be used to monitor all insertions in real time, or to sample every one to twenty cycles for quality control.

The age old problem of matching a personalized letter to a closed face, addressed envelope meant either using an "intelligent" inserter, putting personalized direct mail into a window envelope, hand matching and inserting, or carefully monitoring on a "dumb" inserter, like the Phillipsburg, with the full knowledge that mis-matches were likely to happen.

Now it is possible to eliminate the mis-matches and produce a high-quality personalized direct mailing without having to resort to window envelopes or to investing in expensive new insertiing equipment.

Because the Clear Image Technologies solution eliminates the need to make an investment in new equipment, mailing operations can manage personalized direct mail with older inserters that may already be in use or in storage. AND go green by reducing the carbon footprint that can result from replacing old, perfectly servicable equipment with new, more expensive, more technically advanced equipment.

Reduce, recycle, and REUSE - don't forget the third "R"!

Larry Miyasaka, Clear Image Technologies, gives new life to old inserters with an elegant solution that includes cameras and a computerized matching system. The match system can be used to monitor all insertions in real time, or to sample every one to twenty cycles for quality control.

Larry Miyasaka, Clear Image Technologies, gives new life to old inserters with an elegant solution that includes cameras and a computerized matching system. The match system can be used to monitor all insertions in real time, or to sample every one to twenty cycles for quality control.

The age old problem of matching a personalized letter to a closed face, addressed envelope meant either using an "intelligent" inserter, putting personalized direct mail into a window envelope, hand matching and inserting, or carefully monitoring on a "dumb" inserter, like the Phillipsburg, with the full knowledge that mis-matches were likely to happen.

Now it is possible to eliminate the mis-matches and produce a high-quality personalized direct mailing without having to resort to window envelopes or to investing in expensive new insertiing equipment.

The age old problem of matching a personalized letter to a closed face, addressed envelope meant either using an "intelligent" inserter, putting personalized direct mail into a window envelope, hand matching and inserting, or carefully monitoring on a "dumb" inserter, like the Phillipsburg, with the full knowledge that mis-matches were likely to happen.

Now it is possible to eliminate the mis-matches and produce a high-quality personalized direct mailing without having to resort to window envelopes or to investing in expensive new insertiing equipment.

Because the Clear Image Technologies solution eliminates the need to make an investment in new equipment, mailing operations can manage personalized direct mail with older inserters that may already be in use or in storage. AND go green by reducing the carbon footprint that can result from replacing old, perfectly servicable equipment with new, more expensive, more technically advanced equipment.

Reduce, recycle, and REUSE - don't forget the third "R"!

Because the Clear Image Technologies solution eliminates the need to make an investment in new equipment, mailing operations can manage personalized direct mail with older inserters that may already be in use or in storage. AND go green by reducing the carbon footprint that can result from replacing old, perfectly servicable equipment with new, more expensive, more technically advanced equipment.

Reduce, recycle, and REUSE - don't forget the third "R"!