For decades, printers and packaging converters have made their living by producing client projects. Sometimes they are involved in the concept and design; often they are only brought in when the concept is ready for production. While this may appear to be a reasonable workflow from the perspective of the printer and the client, it’s really not. In a dynamically changing world with a rapid pace of technological change, those responsible for concept and design may not realize all of the options that are available to them.

In a recent WhatTheyThink article, Boutwell Owens CEO Ward McLaughlin said, “When you have a structural designer that been told for so many years that you can’t do certain things, today it is all feasible and the handcuffs are off. The world is open; we are no longer restricted by tooling and cost. People can do things they never before imagined!”

Companies like Boutwell Owens pride themselves on staying on the bleeding edge of technology and taking the risk of investing in those technologies for which careful analysis reveals a new and unique business opportunity.

So let’s take the handcuffs off – for ourselves and for our customers – and leverage the amazing capabilities available in the market today for the betterment of all.

A great place to start is thinking about how paper, a pretty basic element of the printing and packaging industry, can be used differently. We all use it. We print on it. We use specialized finishing techniques to dress it up. We cut it and crease it and fold it and glue it to make unique products based on customer concepts and designs. But there is likely much more than can be done. By combining our knowledge of available technologies with the creativity of customers, designers and artists, we can do some amazing things that will ensure that paper is here to stay as a core element of communication, whether it is on a product package, a point-of-sale display, an art exhibit, a greeting card, or any manner of other ways it can be used to get a message across.

Couture in Bloom

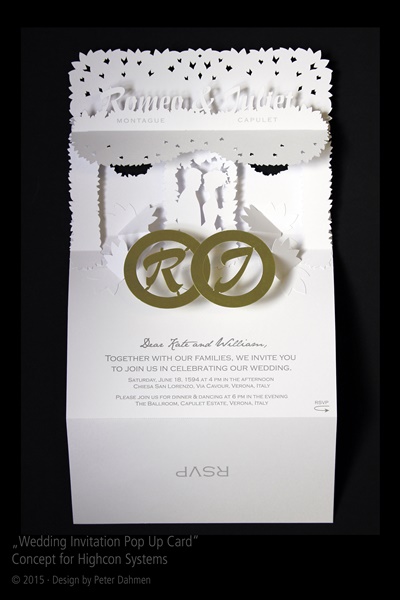

One great example Is a concept pop-up wedding invitation designed by paper artist and pop-up designer Peter Dahmen. A video showing all aspects of the design can be found here. Dahmen also designed an innovative pop-up car key box concept.

Another example from earlier this year was the Chanel garden-themed Paris fashion show. Fashion icon Karl Lagerfeld created a stunning handcrafted paper garden as the backdrop for exquisitely handcrafted fashion.

Greetings to Be Remembered

Perhaps a little closer to home for our audience is the work going on at American Greetings, a 109-year-old company headquartered in Cleveland OH, employing 17,600 people and generating more than $2 billion in annual revenue.

The company’s CEO, Zev Weiss, stated in a recent interview: “There is a symbiotic relationship between design and production. Design knows what can be produced and works to design within those constraints to ensure that costs are not out of control.”

Weiss and his team spend a great deal of time looking for new technologies and capabilities that can advance the business. “We first came across the Highcon Euclid at drupa 2012,” he says. “We immediately saw the possibilities for our business. The decision for us was pretty simple: We could get tremendous quality – in some ways better quality than traditional die cutting – at very low runs, a powerful combination.”

He adds, “We sat down with our design team and showed them how we could do things in ways we couldn’t historically do. It really opens things up and it is very exciting for them. It gives our designers broader capabilities than they ever thought they would have, and they love it.”

American Greetings is producing both samples and production runs on the Euclid with product produced on offset, flexo and digital. “The flexibility of the sheet size is important here,” Weiss says. “The Euclid has a larger sheet size is a huge plus that you don’t see in all digital converting solutions.”

Not requiring dies is another huge benefit, according to Weiss, saving both time and money for the company.

American Greetings has run almost a million sheets through its Euclid since it was installed and is running three shifts. It has enabled the company to bring to market new concepts for cards and other products that have exquisite lacy patterns and other complex die cuts in order quantities as small as one, through full production runs. In addition to new applications, it has enabled the company to take advantage of the Long Tail aspect of its business, basically enabling them to never have to remove a design from the market. “It’s also great for testing purposes,” Weiss says. “In a day, we might run as many as 15 to 20 tests of 400 units each. That scope was next to impossible using conventional techniques and has given us a great deal of freedom to try new things with limited risk.”

Pop-ups is another area of opportunity Weiss identified. “In addition to the short runs, pop-ups are another thing you can do with this technology where historically you would have had to go to China to get it done. It is both a cost and lead time advantage. We can do short runs. We can do them more cost-effectively. We get a 3X or 4X benefit by bringing this work in house.”

Highcon has been looking into some of these extreme designs as well, to build a body of knowledge that will be helpful to its customers. In fact, in May of this year, Highcon announced that Peter Dahmen joined Benny Landa, Zev Weiss and Mike Ferrari on Highcon's Advisory Board, saying, “Peter's passion for paper, combined with the digital capabilities of the Highcon Euclid, has resulted in extreme designs that totally prove the potential of our digital cutting and creasing technology.” In addition to the examples above, you may have seen some of those designs at recent shows, including large, complex pop-ups, and three-dimensional re-creations of architectural icons such as the Eiffel Tower and the Washington Monument.

No Limits

While not every printing and packaging business may be able to tap into world-famous paper designers, they can tap into the creativity of their teams and their customers, using some of these examples as a launching pad. They can also collaborate with design schools in their area to latch on to the creativity of young designers in training.

Taking paper to the next level in this way opens the door –and as McLaughlin said, takes off the handcuffs – broadening the revenue and margin opportunities for print and packaging companies, as well as for businesses like American Greetings whose products are paper-based. It’s a brave new world of paper creativity out there. We’re looking forward to seeing how this type of digital finishing capability will bring changes to the world of print, packaging and beyond.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free