This article is sponsored by Highcon.

Massachusetts-based packaging converter Boutwell Owens is not new to packaging innovation. In fact, the first packaging job the company undertook was the Victrola needle package around the turn of the century – that’s last century, not this one! Boutwell Owens is a privately held company that began as a newspaper printer. Today, Boutwell Owens has more than 200 employees in two locations. Founded in 1887, the company has only had six CEOs. Its current CEO, Ward McLaughlin, says, “We have always stayed on the bleeding edge and embraced technology. But the real difference between us and others is our people. Any of the manufacturers from whom we purchase equipment will tell you our people are outstanding, understand what their futures are, and are dedicated to pushing the limits with a goal of bringing better value to customers.”

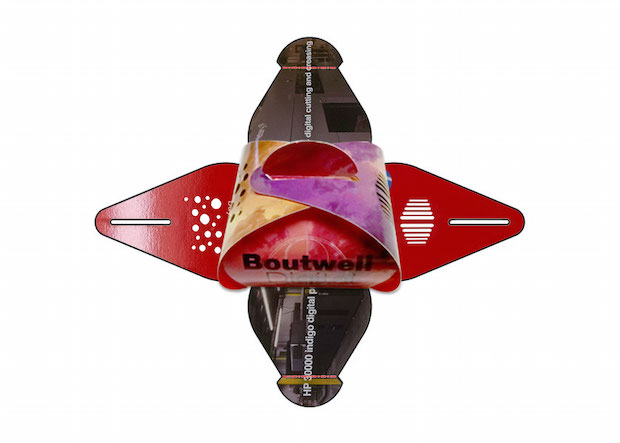

In the spirit of embracing technology, Boutwell Owens was the first North American packaging converter to implement the Highcon Euclid, a fully digital cutting and creasing machine for converting paper, labels, folding carton and microflute. Why? McLaughlin explains, “The biggest attraction is that since it is all digital, there are no tooling costs. This means that we can replace time-consuming manual processes for prototypes and samples, as well as cost-effectively accommodate runs as short as one. This is truly revolutionary for our industry. We can now do the onesies and twosies as well as shorter production runs, prototyping, phase ins/phase outs, and presentations for customers. Since it is all digital, variable data is built in for etching and cutouts. The bottom line is that we can do things that everyone has always been told you couldn’t do.”

Boutwell-Owens used its Highcon Euclid digital cutter and creaser to produce this unusual self-promotional piece

Another innovator is UK-based Glossop Cartons, the first company in the world to install a Euclid. “We looked at the Euclid at drupa 2012,” says Jacky Sidebottom-Every, Sales Director. “You wouldn’t expect a modest company in the UK to be the first to buy that type of groundbreaking technology.” Glossop aggressively promoted the Euclid prior to its install so that work was waiting for it when it was ready to go in the summer of 2013. Now 10% of the company’s converting work is run through the Euclid, and that percentage will continue to grow.

For both companies, one of the biggest advantages of digital finishing is the ability to get involved with clients further upstream. Now concepts can be printed on target substrates, creased and die cut without expensive, time-consuming manual processes. Mock-ups look more realistic and are cost-effective, allowing brand owners and designers to experiment with more concepts without a huge dent in the wallet. Clients can also do customer presentations with production quality pieces. Boutwell Owens has invested in an HP Indigo 30000 digital folding carton press to address short run printing requirements, generating even more volume for the Euclid.

Glossop Cartons has invested in a Xeikon 3300 digital press to address its short run and personalized packaging offering.

For both companies, the sheet size was important. At 28" x 40", the Euclid can accommodate larger press sheets with board weights up to 24 point and microflute up to 47 point.

Both companies peg the average crossover point between digital and analog at about 2,000 sheets, though Sidebottom-Every points out, “We do much higher runs when the cuts are too intricate for conventional processes or items are personalized.” McLaughlin adds, “We have done runs well in excess of 10,000. The DART (Digital Adhesive Rule Technology) polymer used to create crease lines from digital data is rated at 10,000 sheets and we have been able to get a little more than that. But each digital creasing plate costs about $40, and adding another one to complete a long run is not a big deal in the scope of things.” Sidebottom-Every cites a project the company produced within the first month of having its Euclid, saying, “We produced a run of 32,000 cartons for a chocolates carton set consisting of outer sleeve, inner tray and lid as a favor to another carton company. It included very intricate cuts of a flowering trellis leaf pattern. It was a gorgeous piece. We also did a flowering trellis leaf carton for a launch of chocolates in Australia for Christmas 2013, again, a very intricate package. The inner tray was produced in very bold Pantone colors that you could see through the leaf pattern, making for a very striking visual experience that denotes a luxury product.”

Intricate diecuts and vivid colors are among the special effects that Glossop Cartons achieves with its Highcon Euclid system

One unique capability that is changing the way structural designers think about their work is the ability to cut very intricate designs that simply were not possible before. These can be changed from sheet to sheet and really make packages stand out on the shelf. And Glossop is taking this to another level by getting into entirely new revenues from the bespoke wedding business. Sidebottom-Every explains, “We received a call from a designer that produces unusual card products and wanted to do something unusual for an upcoming wedding. We jumped right in, and the result was fabulous. We were able to produce 250 intricately cut invitations, a series of matching die cut wedding lanterns that would each hold a candle and light the path to the altar, and matching round card baubles to affix to chair backs with a ribbon. This opens up a brand-new business stream for us and is something we don’t think anyone else in the UK can do.”

Boutwell Owens is now marketing specialized packaging for golf balls. McLaughlin says, “We can do small quantities of customized packaging for use at golf events and by individual country clubs that allows them to have unique give-aways or to generate revenues by selling commemorative items. This is business we never would have had without the Euclid.” The company has also found a good market in pharmaceuticals, especially when the product is being shipped to countries with small populations or the companies wish to test products with intricate packaging. We see companies taking advantage of this for both over-the-counter and ethical products as an affordable way to try out new things or accommodate shorter runs.”

I found it interesting that both companies used one word to describe the impact this technology has had on their businesses: Phenomenal … I talk to a lot of users of different technology, and that’s not really a word you hear that often. McLaughlin says, “Our Euclid was up and running within three days of delivery. The Highcon team was so well-prepared, their training and support have been outstanding, and when we have questions, we get answers in hours, not days. I have never had an installation go this well.”

Sidebottom-Every comments, “The Highcon folks just don’t say no. They are very proactive and very passionate about moving the technology forward. They have a strong vision of where they want to go, a great deal of conviction, yet they are so open to new ideas from us. It’s been an incredible experience.”

Boutwell Owens’ McLaughlin concludes, “When you have a structural designer that been told for so many years that you can’t do certain things, today it is all feasible and the handcuffs are off. The world is open; we are no longer restricted by tooling and cost. People can do things they never before imagined!” Sidebottom-Every adds, “The Euclid is an exciting addition to our family that has really put us on the map. It’s one of the best things we have done in 32 years.”

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free