HP may have its share of problems in its overall business, but its maniacal focus on expanding its footprint among existing analog wide-format graphics print applications is not affected. At FESPA, it introduced two new high-volume wide-format printers, its most productive latex and UV-curable ink jet printers to date aimed at expanding HP’s footprint among wide-format analog graphics print applications.

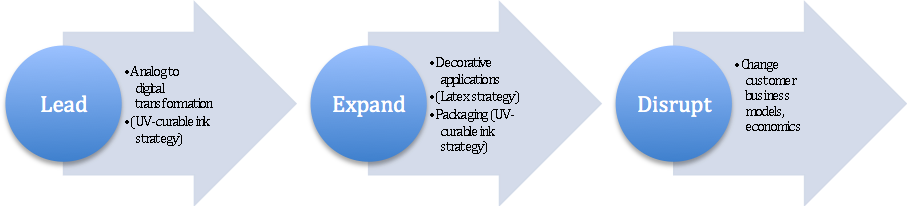

HP’s recipe for its strategic direction is simple:

Leading with UV-Curable Printers—FB10000

Following corporate naming policies, the new HP/Scitex FB10000 is HP’s fastest UV-curable printer to date. At maximum speeds, it prints at 6730 square feet per hour (625 m2), which is the equivalent of 125 5 x 10-inch (1.6 x 3.2m) sheets per hour.

The FB10000 complements the FB 7500/7600 product line introduced four years ago at FESPA 2009 in Amsterdam. Since that time, HP claims to have shipped more than 175 units of the FB 7500/7600 series, cumulatively printing more than 1 billion square feet of UV-curable inkjet output to date consuming 300 metric tons of ink (about 350,000 liters) in 2012 alone.

The six-color FB10000 (but no white ink available yet) is expected to open up further the market for printing of corrugated point-of-purchase display stands and a few retail-ready corrugated boxes (such as consumer electronics boxes where the corrugated box is the primary box). HP believes the FB10000 has the print quality to meet brand owner expectations due to the new printheads incorporated in this model.

Aside from productivity another major breakthrough on the FB10000 is a new set of UV-curable inks. The new inks feature an amazing amount of “stretch,” allowing corrugated POP displays to bend without the ink cracking. Simultaneously, HP claims they also have very high adhesion, even on acrylics. The monomer-based inks cured with cold-mirror arc lamps have an improved formulation that elongates the polymer chain. While HP is careful not to disclose the exact changes, we suspect it may have something to do with an increase in oligomers, which enables greater ink stretch/flexibility. Using a delayed cure feature, the FB10000 can also create matte, satin, or high-gloss finishes without using a spot varnish. Depending on the effect, the area where the effect is desired may have to be printed twice. This does slow down the printer, but the decrease in productivity is directly correlated to the area coverage of where the custom finish is desired. For most images, the decrease in speed will not be significant.

The FB10000 is intended to “lead” in helping analog corrugated display converters shift to digital inkjet printing. HP believes that combined with its marketing muscle and the FB10000’s productivity and print quality digital printing is now within reach of corrugated converters.

Expanding Applications—Latex 3000

HP introduced its latex ink technology at DRUPA 2008; since that time, well over 1 billion square feet of output has been printed cumulatively on the 15,000 latex printers installed. Latex ink technology has been so important to HP, the time has come to rebrand the entire portfolio, eliminating the L-series identification for one/two-tier distribution and LX-series identification for mainly direct sales (in Western economies). Henceforth, HP will have three wide-format printer lines: DesignJet (aqueous inks), Latex (latex inks), and Scitex (UV-curable inks).

Figure 1: Latex Model Portfolio—2013

|

Old model name |

New model name |

|

DesignJet L26500 |

Latex 260 |

|

DesignJet L28500 |

Latex 280 |

|

DesignJet LX 820 |

Latex 820 |

|

DesignJet LX850 |

Latex 850 |

|

Latex 3000 |

The Latex 3000 is the fastest HP Latex printer to date, printing up to 1950 square feet per hour. It is intended to replace older UV-curable roll-to-roll printers, remaining aggressive solvent printers, as well as to open up new markets enabled by its throughput and running cost efficiencies.

The Latex 3000 features seven HP thermal printheads. The seventh printhead is for what HP calls an “optimizer” fluid, effectively a pre-coat that prevents dot gain before curing. The optimizer immobilizes the pigments chemically in the printzone and enables the faster throughput speeds while simultaneously reducing the heating energy required from 15 kWh in other Latex models to 9 kWh.

Of note is that high print speeds result in moisture vapor occasionally floating up from the printer. The 12 800W fans can create—depending upon the substrate—more vapor than the 15L vapor/condensation collector can absorb. HP expects the 15L tank to be emptied about every three weeks, highly dependent on a range of factors. Incidentally, IT Strategies calculates that at 9 kWh, the drying cost at a U.S. average $0.15/kWh is going to represent well under 0.5% of the total cost of print.

Newly formulated inks also feature a “slip agent,” a polymer that aids scratch resistance. Effectively, it creates an encapsulating film protecting the colorants and the substrate much the same way a coating on a watch crystal prevents scratches. The main benefit is that it helps prevent damage during the installation process of the print. The formulation reduces the coefficient of friction at the surface without preventing lamination for those applications that still benefit from lamination (for gloss, etc.).

Bottom Line

HP is pushing the productivity envelope with its new wide-format graphics printers. Clearly its R&D activities have not slowed since DRUPA 2012. We can only wonder when all these advancements will trickle down to the other side of the product portfolio.

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free