Billions of dollars a year are on the line for companies as they seek ways to ensure that the products sold with their logos and branding are authorized and authentic. The proliferation of counterfeiting requires brand owners and their converter/printer partners to work together to create a multi-layered protection plan so that their packaging and labels protect their brands and deter those trying to profit at their (and their reputation’s) expense.

Counterfeiting’s Toll

Counterfeiting is a global problem that is growing by leaps and bounds every year. The International Anti-Counterfeiting Coalition (IACC) estimates that since 1982, worldwide counterfeiting has grown from a $5.5 billion per year industry to a $600 billion per year industry, and that it costs U.S. businesses between $200 billion and $250 billion annually.

Counterfeiters have become so good at their illegal jobs that spotting the difference between a legitimate and counterfeit product can be daunting. They have many ways to subvert legitimate brands. They may take an out-of-date – but legitimate - product and sell it in packaging and labels that have been faked. Sometimes, everything – including the packaging, labels and product itself – is counterfeit. Criminals might also use legitimate packaging with knock-off products.

Brands Have the Means to Fight Back

Using today’s digital printing technologies that build security and anti-counterfeiting measures into the design of the packaging and labels from the beginning can substantially increase a brand owner’s confidence that their products won’t be stolen or their reputation damaged. The investment in these measures is quite reasonable, and many of these measures are integrated directly into the digital printing process.

Microtext

Commonly used with currency and bank checks, microtext is text or coding that is printed at about one point size, so small it cannot be seen except with a magnifying glass. Microtext is very difficult to replicate or copy without using advanced detection equipment. Microtext characters can be inserted into overt images, text and other design elements without the consumer being aware of them. Counterfeiters don’t have the capability to reproduce microtext, and will simply copy the visible elements. A handheld magnifying glass can tell an examiner that a product is authentic or not.

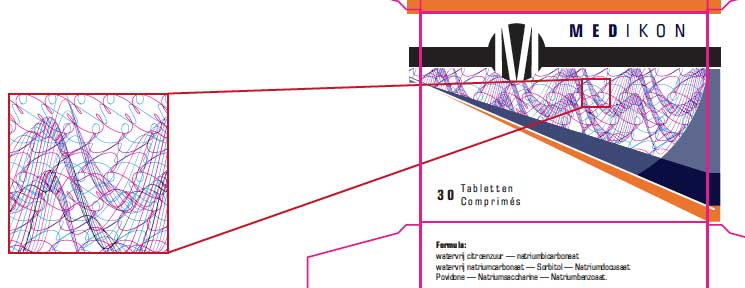

Guilloches

Guilloches are highly complex and very fine, curved bands of lines, commonly included in documents such as bank notes to prevent forgery. They can also be used in the background of a package design, and are very difficult for counterfeiters to replicate using ordinary equipment, such as a color copier.

Variable Images and Illustrations

Variable data printing is the ability to introduce elements (such as text, images or graphics) that are unique to each piece in a single production run. For security, variable printing makes counterfeiting much more complex.

One effective example of variabilization is the use of cryptographs. A cryptograph is a series of dots, each about 20 micron, that are printed on a package in a random pattern which can only be authenticated by a digital scanner using specialized software. Typically, in a digital printing environment, the designer includes the cryptograph pattern in the artwork file that is sent to the printer.

Authenticity can be determined by sending the image with the cryptograph for computer-aided verification.

Security Substrates

Packaging and labels that require a high level of security need to start with a high quality substrate. Leading fine paper producers offer substrates with advanced security measures, including:

- Fluorescent fibers: These are fibers that have been mixed in to the pulp during the paper manufacturing process and are not visible unless viewed under a special light.

- Microprinting fibers: These small, embedded fibers are randomly distributed throughout the paper and can only be seen upon close inspection.

- Reactive anti-fraud chemicals: These are chemicals which cause a reaction, such as a stain to appear, if a label is tampered with.

- Watermarks: Watermarks can be embedded into the design of the package to authenticate products. These can be either generic or customized for a brand, and can be very cost-effective when built into the prepress process.

- Taggants: Taggants are microscopic substances that can be either added to the substrate itself, or to the ink or toner, to act as a trace. Taggants don’t impact the quality of the ink or the substrate, but cannot be removed. It takes a specialized taggant reader to detect taggants and verify that a product is authentic.

- Embedded holograms: Two-dimensional holographic images can be embedded into the substrate either overtly or covertly and can be used for product authentication. They are very difficult to duplicate.

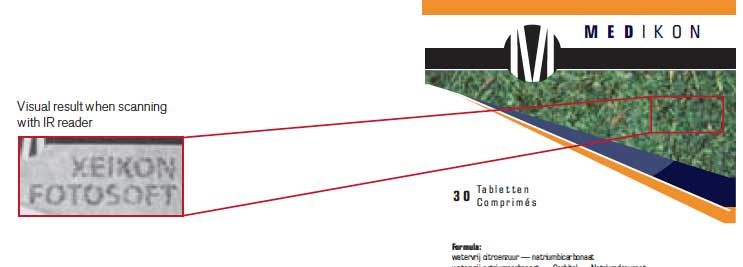

Toner Technology

Dry toner-based digital printing offers multiple brand protection features that converters can provide to their brand owner clients. It enables the use of currently used security substrates which simplifies the process. Unlike the dry toner, other types of toners/inks cannot print on existing security substrates. Clear toner is one of the most widely used among these security features. It’s transparent and ultraviolet reflecting, and can be used to create watermarks that can only be seen by a human looking at the image from a certain angle under a light source, but won’t show using a copier or scanner. Other spot colors are possible as well. That includes custom made toners produced to the requirements of the end-customer.

Taggants are microscopic chemical markers that can be added to the substrate or the toner itself, to allow various forms of verification. They are already used for banknotes, identification documents and value papers as well as packaging for tobacco products, alcohol or pharmaceuticals. Taggants are invisible to the human eye in print and can only be detected by special readers. They are not removable and they are very difficult to reverse engineer. Taggants are embedded in the toner during the production process. Once the taggant toner is ready, it is only distributed through a specialized service provider who has expertise in managing security solutions and has a strict chain of custody. If taggant toner is being used to print variable information it makes the packaging virtually impossible to duplicate.

In addition, if a digital press has the required combination of resolution, precise pixel placement and toner handling then raised images can be produced. Printing text or graphics in black using four toners on top of each other creates a tactile height difference that cannot be reproduced by a photocopier.

Bar Codes

Two-dimensional barcodes and quick-response (QR) codes are used throughout the packaging industry to track and trace items. Digital printing technology is attractive for these applications because the printer can create unique bar codes for each unit. If a reader scans a bar code that is duplicate or invalid, it can identify an item that is suspected of being counterfeit.

Printing in the Vanguard

Package printing stands on the front line of the fight against counterfeiting. By using technology printers are striving to make the bar so high and the process so expensive that it becomes impractical for counterfeiters to make money. With today’s digital printing technologies, converters can incorporate multiple layers of security, combining multiple security features into the prepress process to discourage those who would make or sell counterfeit products.

Further Information

Readers who need more information on this topic can contact Andy Dwivedi at [email protected]

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free