Two weeks from today, drupa will open with its traditional profusion of printing equipment: prepress, press, and postpress machinery as far as the eyes can see, the feet can walk, and the brain can comprehend. The “big three” German press manufacturers, Heidelberg, KBA, and MAN Roland, will march at the head of the quadrennial iron parade as they always do—but equipment won’t be the only aspect of the message that each hopes to convey at the show.

Driving equipment sales alone no longer suffices as a strategy for survival in the North American marketplace, where the long-term outlook for equipment sales growth is modest at best.

This year, the three companies are emphasizing business consulting services as key elements of their offerings to customers. Each comes to drupa with an expanded menu of programs for analyzing and optimizing its customers’ operations not just in terms of production hardware, but with an eye toward improving general business management as well.

The programs are new, having been launched or rebranded within the last year. All, however, reflect their owners’ understanding that driving equipment sales alone no longer suffices as a strategy for survival in the North American marketplace, where the long-term outlook for equipment sales growth is modest at best.

The programs are similar in operating on a fixed fee-for-services basis and in being available to any printing company that wants to use them, regardless of the brand of equipment that the printer happens to operate.

The organizational models differ. At Heidelberg, the consulting arm is an internal business unit. MAN Roland offers what it offers through an owned but independently operating subsidiary. KBA has partnered with an MIS developer and several other graphics system suppliers to create a separate entity for consulting services. The programs are similar in operating on a fixed fee-for-services basis and in being available to any printing company that wants to use them, regardless of the brand of equipment that the printer happens to operate.

Retooled and Ready

Although the big three have been offering business support services of one kind or another for many years, the consulting programs that they will bring to drupa are recent creations in their present forms.

Steen Jensen, in charge of the Business Consulting services unit at Heidelberg, says that the program was launched in the U.S. about a year ago after an auspicious start-up in Australia. There, says Jensen, Heidelberg was able to “increase its market share significantly” after assisting Down-Under printers in business analysis projects related to M&As. The tools and procedures developed in these assignments became the basis of what is now available to printers in the U.S.

In January of this year, MAN Roland combined all of its consulting services for web and sheetfed offset printers under the “printadvice” brand, an element of its “PRINTVALUE” brand family of customer support services. Assistance from printadvice is delivered by a subsidiary that has been in existence far longer than the brand: Eurografica Systemplanungs GmbH, founded by MAN Roland in 1970 to provide consulting, architectural, and engineering services to newspapers and commercial printers.

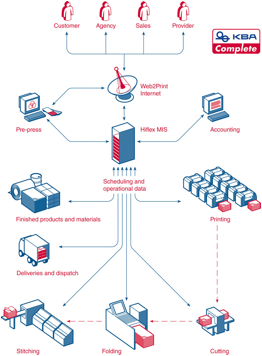

Newest of all is KBA Complete, a 50/50 joint venture launched by Koenig & Bauer AG and the Hiflex Group on March 31. Also participating as technology partners are Kodak, MBO, Muller Martini, IPM, and ClimatePartner, whose systems are compatible with MIS solutions from Hiflex. As an independent consultancy, KBA Complete offers help in implementing JDF workflows, MIS, print process management, process standardization, and climate-neutral print production. “Our mission,” says Thomas Göcke, director of marketing, “is to make our customers more profitable.”

No Shortage of Takers

Profit-seeking printers have been keeping the three programs busy. According to Jensen, Heidelberg’s consulting unit completed 16 business audits in the U.S. during its first year of operation, catering to a “mixed bag” of printers by size and specialty. Thomas Schonbucher, director of the printadvice program, says that Eurografica typically handles about 150 consulting projects per year, with six to 10 of them occurring in the U.S. About 60% of the assignments take place at newspapers, 25% to 30% at commercial web plants, and the remainder at sheetfed firms. Göcke reports that KBA Complete—in business for six weeks as of this writing—has landed its first U.S. consulting job at a commercial plant on the West Coast and is discussing projects with several other stateside printers.

Although the types of services rendered vary from program to program, the consulting methodologies are more or less the same. Heidelberg’s principal focus is on helping printers to shape and carry out equipment investment plans by analyzing current operations and forecasting future needs. After making an initial presentation either on site or by webinar, Heidelberg’s consultants amass volumes of production data that let them scrutinize plant operations all the way down to a shift-by-shift, operator-by-operator level of detail.

Among the many factors weighed, says Jensen, are makeready and washup times, color and coating profiles, and seasonal volumes—anything and everything that will support a fully fact-based recommendation for the kinds of production capability that the customer should acquire. The Heidelberg analysts then “clean” the data to eliminate errors and discrepancies. The customer is expected to participate by completing a spreadsheet that seeks detailed information about job planning and execution.

What Are the Options?

Gathering the data, says Jensen, typically takes from one to three months; the crunching can be done in five to 10 working days. Plant tours and operator interviews are also parts of the process, but Jensen emphasizes that the heavy reliance on verifiable production numbers is what sets Heidelberg’s consultation apart. Now the customer can be presented with an “analysis of options” that compares current production costs to those that can be anticipated with new equipment. The analysis, says Jensen, can be done for prepress, postpress, and workflow systems as well as for presses.

If the customer desires, he adds, the consultation also can examine work volumes performed for individual clients—the first step in understanding the extent to which each account contributes to the printer’s overall profitability. Benchmarking the printer’s performance against standards at comparable operations is something else that a consultation might include, as is advice on material handling and plant layout.

On behalf of MAN Roland, Eurografica consults in five areas: investment planning; production facility design; organization and management; production system design; and process optimization. Although helping customers plan their future capabilities is the essence of any consulting assignment, says Schonbucher, it’s equally important to help them make the best possible use of the resources they already have. That may mean focusing not just on equipment, but also on the human element: “ Eighty percent of the problems we deal with are people issues,” Schonbucher says.

“360º View of Consultancy”

Striving for what Schonbucher calls “a 360º view of consultancy,” Eurografica looks as closely at a customer’s table of organization as at its list of equipment. What every printer should have in place, he says, is a flat management structure that embraces clear job descriptions and equally specific standards for qualified personnel—matters that should be addressed before a major investment in equipment is contemplated.

Like Heidelberg, Eurografica relies upon detailed fact-finding in a process that draws its conclusions strictly from real performance data: for example, actual vs. promised delivery dates, the frequency of web breaks, manning levels, labor rates, energy costs, and other hard information from the production floor. Depending on the nature of the assignment, says Schonbucher, the information-gathering phase could be over in few weeks or extend from two to six months. In the most intensive assignments, Eurografica representatives might spend up to 14 days at the customer’s site observing both day- and night-shift operations as needed.

The deliverable, says Schonbucher, is a step-by-step guide to process optimization in which “all of our improvements will be valued.” This means that ROI calculations will be attached to each recommendation, enabling the customer to see how much will be saved, for example, by measures taken to reduce waste.

There is little point in achieving a five-minute makeready on a press “if you don’t know where the paper and the plates are.”

For KBA Complete, the consulting keynote is MIS. Without it, notes Göcke, a printing business cannot be profitable even if it operates the most up-to-date production equipment—a scenario that applies to many printers still struggling with spreadsheets and other MIS substitutes in vain attempts to keep their production activities in view. There is little point, as Göcke puts it, in achieving a five-minute makeready on a press “if you don’t know where the paper and the plates are.”

KBA Complete proposes to keep printers out of the islands-of-automation trap either by optimizing the MIS assets they already have or by recommending a solution from Hiflex, a German software developer that claims to have conducted more JDF-compliant installations than all other MIS vendors combined. In every case, says Göcke, KBA Complete will insist that the solution be truly open and fully JDF-compatible, as opposed to “an open system in a closed room” that can integrate only devices from the same manufacturer.

Quick Check, Then Deep Dive

A “quick-check” analysis completed in one or two days gets the process started by identifying the customer’s existing MIS capabilities—assuming that there are any—and estimating the time it will take to implement the solution that KBA Complete recommends. Then, says Göcke, at the customer’s invitation, the consultants can “dive deeper” in an end-to-end investigation of the plant’s workflow and each staff member’s role in it.

They also will try to gather as much production data as they can, given the extent of the plant’s record-keeping. In situations where numbers are hard to come by, says Göcke, it may be possible to form a reliable picture by combining benchmark data from trade associations with whatever details the customer can provide.

KBA Complete merges all of this input in a formal proposal either to upgrade the plant’s current MIS capability or to install a first-time system that meets the customer’s needs. This may involve recommending MIS products from Hiflex, or it may not. “If the customer has it, we’re okay with it,” says Göcke, adding that Hiflex products will be advocated when it can be shown that they will outperform the best that an existing system can be optimized to do. What’s more important is convincing the customer that a well-chosen MIS solution can, as Göcke asserts, “easily” deliver a triple-digit ROI in five years.

Brand agnosticism is a trait shared by all three programs, which don’t discriminate on the basis of customer relationships.

In fact, brand agnosticism is a trait shared by all three programs, which don’t discriminate on the basis of customer relationships. Schonbucher says that when Eurografica offers investment advice, it does so only in terms of capability—no brand specifications of any kind are made. As a result, he says, the consulting report can be presented as a “neutral document” that lets the customer think about what equipment to buy, not whose.

Anyone and Everyone

Jensen says that Heidelberg will consult “for anyone out there” and that going into a plant full of another manufacturer’s equipment doesn’t faze it—about one-quarter of the consulting unit’s assignments to date have been performed for competitive accounts. Schonbucher notes that while Eurografica provides printadvice consultation under contract to MAN Roland, it also has executed “stacks” of confidential projects for printers using Goss, KBA, and Heidelberg products.

KBA Complete’s very first MIS installation took place in a MAN Roland-equipped commercial plant near Munich, Germany. “We really don’t care what the customer has in the shop,” says Göcke. If anything, the more mixed the environment in terms of branded equipment, the more satisfying the consulting assignment—there’s that much more opportunity for system integration.

The three programs charge flat rates for their consulting services after assessment of needs. The fee can be can be bundled in the purchase price of new equipment from Heidelberg and MAN Roland (although Schonbucher says it’s “unlikely” that Eurografica would structure the payment in this way). KBA Complete bills for the initial “quick-check” analysis and then quotes a fee based on the estimated number of days needed to install whatever the consulting proposal calls for. As a part of its ROI calculations, Eurografica may suggest that it be paid a percentage of the savings that will realized over time by implementing its recommendations.

Three Good Reasons

It’s clear that these consultancies will never be the kinds of moneymakers that can rival what the big three can earn from selling equipment. Why, then, are any of them in the consulting business in the first place?

Although the spokesmen for the programs requested that the dollar and euro amounts of their fees not be published, it’s clear that these consultancies will never be the kinds of moneymakers that can rival what the big three can earn from selling equipment. “We are not a money-spinner,” Schonbucher says of Eurografica. “We are a break-even company.” Why, then, are any of them in the consulting business in the first place?

Jensen speaks for everyone in answering that nothing deepens a relationship with a customer more thoroughly than a result-getting consulting assignment. “The more successful our customers are, the more successful we’ll be,” he says, adding that consultations sometimes can turn into a sales opportunities for support services, training, and other Heidelberg offerings in addition to equipment.

According to Göcke, KBA has lent its name and its resources to KBA Complete because it realizes that a business strategy based solely upon selling state-of-the-art equipment is no longer enough. “Printers want options, and we must sell open systems,” he says, adding that plants operating only one brand of production machinery are rarities nowadays.

Schonbucher points out that when MAN Roland sells a web press to a newspaper publisher, 20 or more years may pass before that customer is ready to purchase again. There’ll be much relationship maintenance to perform in that long interval, and printadvice, as provided by Eurografica, is MAN Roland’s answer for keeping the ties strong.

Throughout drupa, MAN Roland will be promoting printadvice and the rest of its PRINTVALUE brands at stand D28 in hall 6. Heidelberg will showcase all of its services at a pair of business and information areas in the centers of halls 1 and 2. KBA will have a video lounge for KBA Complete at stand B45 in hall 16. For the sake of getting the big picture of the big three at the big show, visitors shouldn’t overlook any of these essential presentations.

Please offer your feedback to Patrick. He can be reached at [email protected].