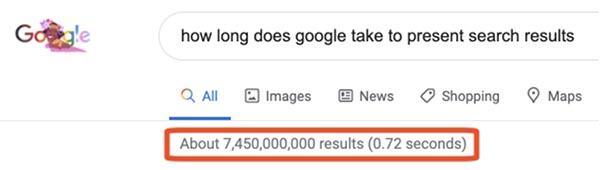

Do you know where your customers get their expectations for speed and responsiveness?

They type anything into Google and it gives the user the perception of searching the entire internet (doesn’t really do that) and then returns the results in a fraction of a second. A fraction of a second. This timing meets the expectations of the most impatient among us.

OR possibly this…

If you enable Amazon’s patented 1-Click (Amazon's U.S. patent expired on September 11, 2017), you find what you’re looking for and in one click you have placed the order using the defaults you set up in your Amazon account.

These are two pretty steep expectations set by two of the most successful companies on the planet. I’m not saying you have to meet these expectations. I only use these as a reference point because many of us are still measuring our estimate/quote turnaround times in days and we require the customer to exchange several emails, look at an attached PDF, provide approval or changes, and spend a lot of their precious time.

The estimating process is one of the most frustrating parts of purchasing print. Think about your shopping experience; how many of us get annoyed when you can’t easily get the price of something? When I run into “call or email for a quote” on any website, I typically move on to find an alternative. We are in a unique position because printing is a custom manufacturing process so some quoting is absolutely necessary.

The estimating process is one of the most frustrating parts of purchasing print. Think about your shopping experience; how many of us get annoyed when you can’t easily get the price of something? When I run into “call or email for a quote” on any website, I typically move on to find an alternative. We are in a unique position because printing is a custom manufacturing process so some quoting is absolutely necessary.

I was taught a very important lesson by a category procurement officer at one of the largest US banks. Under his category management, the spend he managed was in the billions (with a B). He said, “We have a policy for three quotes per procurement event, but nothing says we have to wait for all three to come in before we make a decision.” Estimating is a race; if you continue to measure it in days you’re not going to win very many estimating races.

A custom estimate on every job is a security blanket that the print industry has been holding onto well into their teen years. We should have given that blanket up as a toddler; it's embarrassing that we’re walking around with it in high school. I know what you’re thinking: “This woman doesn’t know what she’s talking about; how else are we going to make sure we’re making money if we don’t precisely estimate each custom job?” I am not advocating for “no estimates”; I am advocating for a lot fewer estimates and when an estimate is needed for it to be a lot faster.

Let’s begin with doing a lot less estimating. This is the best way to speed estimates up: reduce the number of estimates you’re asking your estimators to do so that they can turn them around quicker. You have to break down your attachment to every job needing an estimate. Every job doesn’t deserve an estimate for the following reasons.

- Doing an estimate costs you money. Doing an estimate on some jobs will essentially make them not profitable (if you’re accurately calculating labor costs).

- Please don’t tell me that your estimators are sunk costs. If they are doing an estimate on every job and therefore the jobs that actually warrant an estimate can’t get turned around in less than 48 hours, then the opportunity cost of your slowness is costing you real money.

- Doing an estimate costs your customer time. You will lose and/or frustrate customers if you require an estimate on every single job.

- You know when a customer wants their price? Immediately. Not in a few hours, not tomorrow, and not in two business days. They want to know right now because they need to make business decisions based on that price.

- There is a portion of your business that you can price without doing a manual estimate.

You have to look at your business and realize that there are patterns that can be identified and then build out processes that allow as many jobs as possible to skip the estimating department. I know you’re a custom manufacturing business, but you can “productize your business” by looking at patterns. These patterns are similar manufacturing specifications that can be pre-priced and they don’t have to be fixed prices. You can have multiple prices based on the customer’s standing with you. This requires upfront work: identifying the patterns, calculating your costs, and then setting your pricing based on the margins you want to achieve. Why would you invest time and money to do this work? When you do this work once, you are then allowing a segment of your business to bypass estimating. This gets the pricing out faster to sales and customers and frees up time of your estimators so they can respond in hours rather than days.

One of the ways this whole idea gets a lot of resistance is that the very first thing people bring up (which you might be thinking of right now) is the most complex and complicated job you can think of. It usually goes something like this: “You don’t understand our business. Let me tell you about this 17-part, six-figure job we just spent three full days estimating!” I am not talking about that job—I am talking about all the repeatable jobs that get in the way of your estimators who really need to focus on the complex jobs where job engineering is key.

Another fear is that if we don’t estimate every single time we’ll lose out because we aren’t constantly updating our costs (e.g. stock prices change). Again, I think we discount that estimating costs you money and your customers time. I was working with three different labels and packaging printers—here’s the range of how they approach pricing in a segment of the print industry that is 85% re-orders!

- Printer #1 estimated just three quantities: a minimum, a normal, and an exceptionally high quantity (for example, 5,000, 50,000, 200,000). Their web-to-print solution used this pricing for online ordering. In the calculation of the prices over a six-month period, 98.5% of the pricing was around the 50,000 quantity rate (their normal rate). On only a very few occasions did they order a lot less or a lot more and got the other pricing. So the printer didn’t do one estimate for reorders and the customer got pricing as they were checking out. No emails, no quote approvals, just placing the order and getting an email confirmation.

- Printer #2 had a policy that if the customer didn’t order exactly the quantity that was quoted they re-quoted at the quantity requested. This means they did a quote most of the time because they quoted again when the customer ordered 55,000. This slowed down the ordering process, and added more labor to customer service and estimating. Their thinking was that they needed to give the customer a precise quote for the precise quantity. Yet, the Print MIS where the pricing was being stored allowed you to set up to 18 price breaks for each product!

- Printer #3 was convinced that all reorders should be quoted because they were afraid that stock costs could rise and then prices would not be properly adjusted. They wanted to set up their web-to-print solution and allow customers to place orders, but all of them would require quoting. My take on this is that if you want to really frustrate your customer ask them to use your online ordering system (make it look like you care about their time), then frustrate the hell out of them by not providing pricing!

I tell you the story of these three printers because they are in a very similar market. When I look at their customers, I see all the same segments there. Their different approaches reflect leadership. Are you setting up your business to be as easy as possible on your customers? Web-to-print in the reordering process should bypass both estimating and customer service. If you can allow your customers to place re-orders and have them go directly into production because they have both pricing and artwork already agreed upon, you are basically creating an express lane to your presses (skipping the carpeted area of your print business).

Estimating is a race. You should be looking at your print business to figure how to create express lanes that skip the estimating department all together. In fact you should task your estimating department on finding ways to set up the Print MIS tool you’re using for estimating so that more and more jobs do not require a human estimate.

Discussion

By Robert Lindgren on Jul 09, 2020

Jennifer...

This line is the gem of your whole wonderful article:

You can have multiple prices based on the customer’s standing with you. This requires upfront work: identifying the patterns, calculating your costs, and then setting your pricing based on the margins you want to achieve.

Multiple prices based on the customer's standing with you is the key to getting as much as the customer is willing to pay but also getting the order. An enormous amount of printer money is wasted on estimates that either don't turn into an order or leave money on the table because they are focused on arbitrary and usually outdated concepts of "cost" and which ignore the value to the customer and competitive alternatives.

By Dave Hultin on Jul 10, 2020

This is article contains gold-standard thinking! Jennifer, lots of good wisdom here!

And the picture that these words paint...

>> A custom estimate on every job is a security blanket that the print industry has been holding onto well into their teen years. We should have given that blanket up as a toddler; it's embarrassing that we’re walking around with it in high school.

...will be bouncing in my thoughts for many days to come!

By Jennifer Matt on Jul 13, 2020

Dave and Robert - what I like about what covid-19 is doing to us is really looking at our "this is the way we've been doing it" behaviors. The world has changed rather dramatically in our life times; primarily due to the crazy-making pace of technology. We have to adapt our processes to take advantage of new tools and to meet customers updated expectations. I don't aspire to be "cutting-edge" because that takes lots of effort but what you don't want to be is a laggard - remaining with processes you used 20 years ago without questioning them.

Jen

By Dave Hultin on Jul 13, 2020

Agreed! Leaving the world of estimating for a moment, think of all the electricity and advertising dollars pumped into high-traffic venues like NY Times Square. So much of that is just wasted because people are walking around with their noses down in their phones. (Not judging, I'm guilty too!) Both covid-19 and technology have almost certainly led to "recalibrating" some of those advertising dollars.

By Scott Sutton on Jul 20, 2020

I think this pertains to B2C printers much more than B2B. Instant quoting might be nice for the person looking to get 250 business cards, but it also turns printing into a commodity. You wouldn't expect a construction company to give you an instant price on home remodeling, because that's a value-based service. If you want to be paid what you're worth, don't try to imitate VistaPrint, just provide better value.

By Robert Lindgren on Jul 20, 2020

Actually, it's just the reverse. You do want to be paid for value--what the job is worth to the buyer. That's the point of disconnecting pricing from "cost" defined by BHRs and materials markups and on to customer relationships and job importance. Jennifer's article noted the capability of the estimating package to differentiate between customers and/or jobs. The goal of a pricing system should be to charge as much as the customer is willing to pay which is a function of the benefits conferred on the customer by the job in question--is it a key component of a new product launch or a throwaway package insert.

By Jennifer Matt on Jul 20, 2020

Scott,

This article is about making Estimating faster and less of a burden for the customer. It is not about "not estimating anymore". You have to estimate but you need to look at what you are estimating - not every job deserves an estimate. Too many printers are still estimating every single job.

Jen

Discussion

Join the discussion Sign In or Become a Member, doing so is simple and free